Method and apparatus for monitoring the deviation of an object from a sequence and corresponding control system

A technology for items and sorting systems, applied in the direction of conveyor items, general control systems, conveyor control devices, etc., can solve problems such as inability to detect incorrectly executed item sorting, and achieve the effect of reliable inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

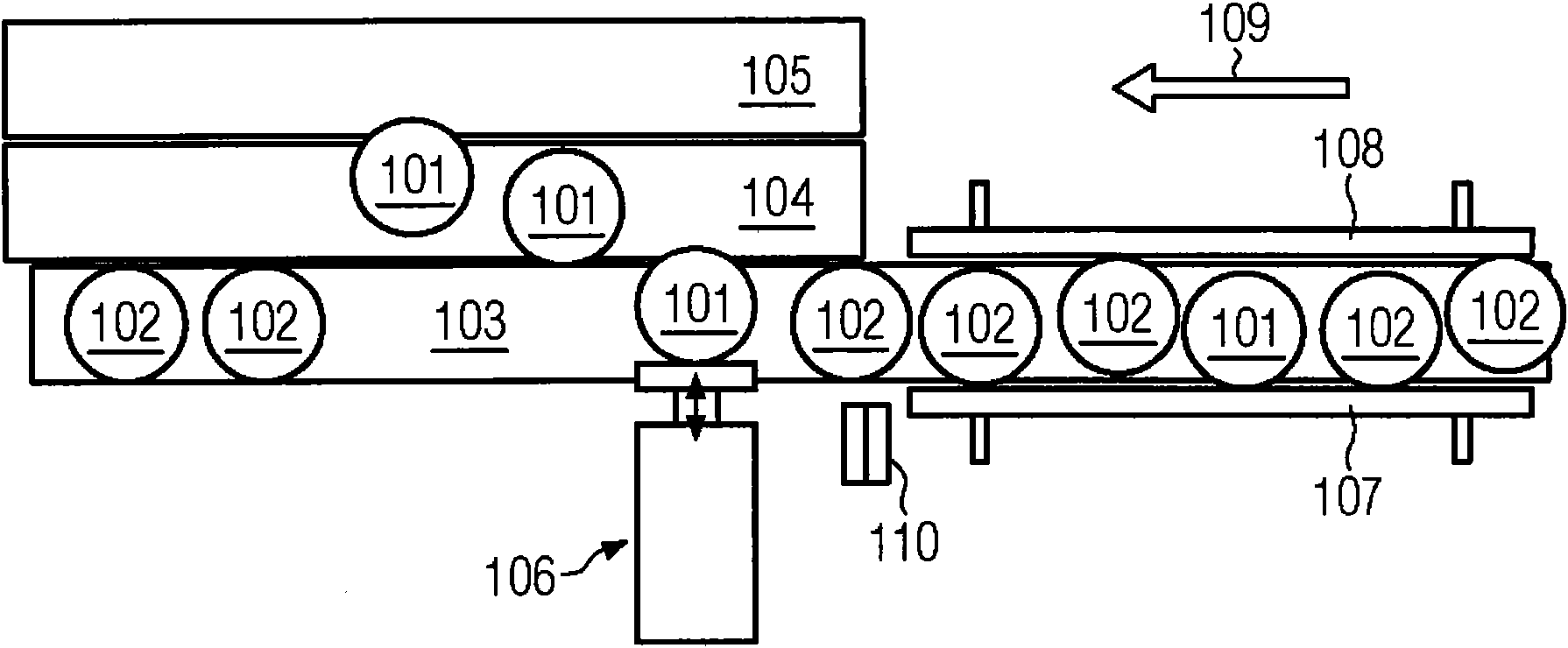

[0058] figure 1 An exemplary sorting system is shown. in addition figure 1 A sequence of items is shown, including items to be sorted, such as defective items 101 , and items not to be sorted, such as non-defective items 102 . In a conveying direction 109 , the sequence of articles is conveyed on a conveying element 103 , for example a conveyor belt. figure 1 Also shown is a sorting system 106 comprising pushers defined by electronically controlled linear motors.

[0059] By means of the pusher, in particular by means of contact elements of the pusher, such as pusher plates, the objects 101 can be sorted from the sequence of objects and arranged on the conveying elements 104 and 105 respectively from the positions from which they can be ejected . Arranged upstream of the sorting system 106 in the conveying direction 109 of the sequence of items is a sensor 110 which is realized and / or configured such that it can identify the items 101 to be sorted. The sensor 110 may be, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com