Method, device and system for detecting vibration of arm frame of engineering machine, and engineering machine

A technology of engineering machinery and boom, which is applied in the field of vibration parameter measurement, can solve the problems of difficult and unfavorable data collection, difficult to determine the position of the measured point, etc., achieve accurate detection results, facilitate detection, and avoid manual recording of the coordinates of the end of the boom the effect of the work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

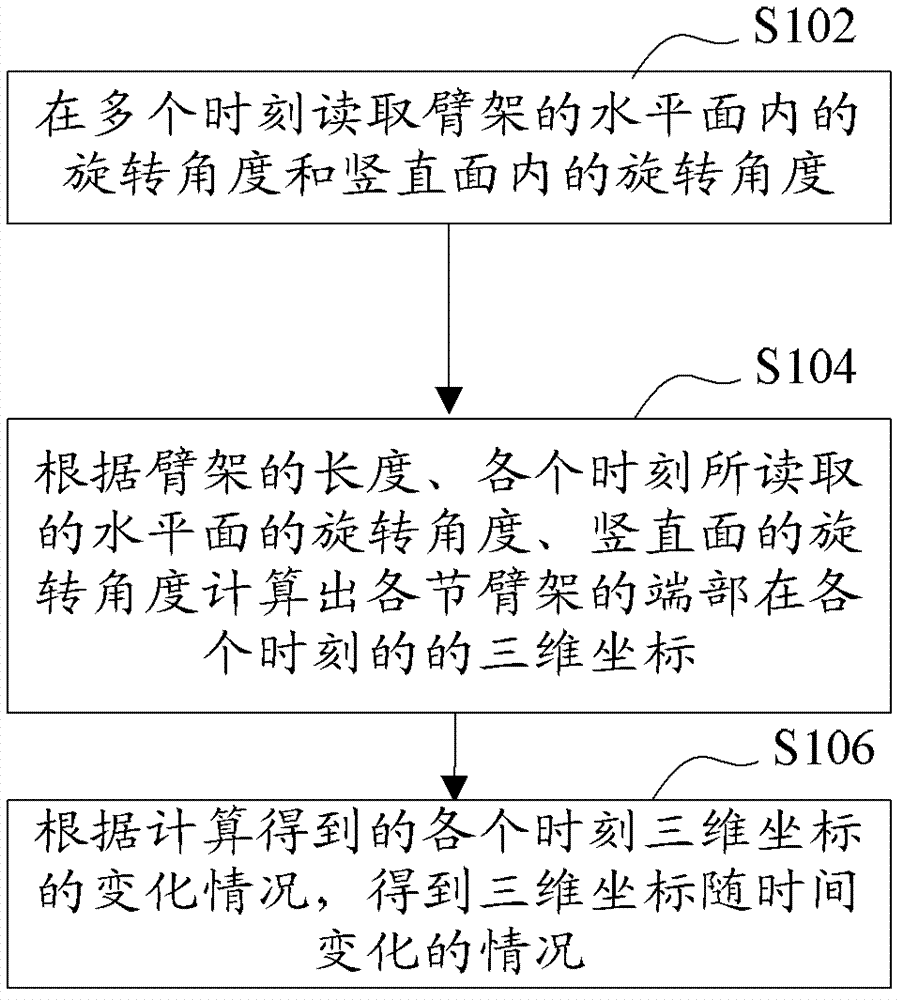

[0025] Such as figure 1 As shown, in the first embodiment according to the present invention, the construction machinery to be detected is the boom of the concrete pump truck, and the method for detecting the vibration of the boom of the concrete pump truck includes:

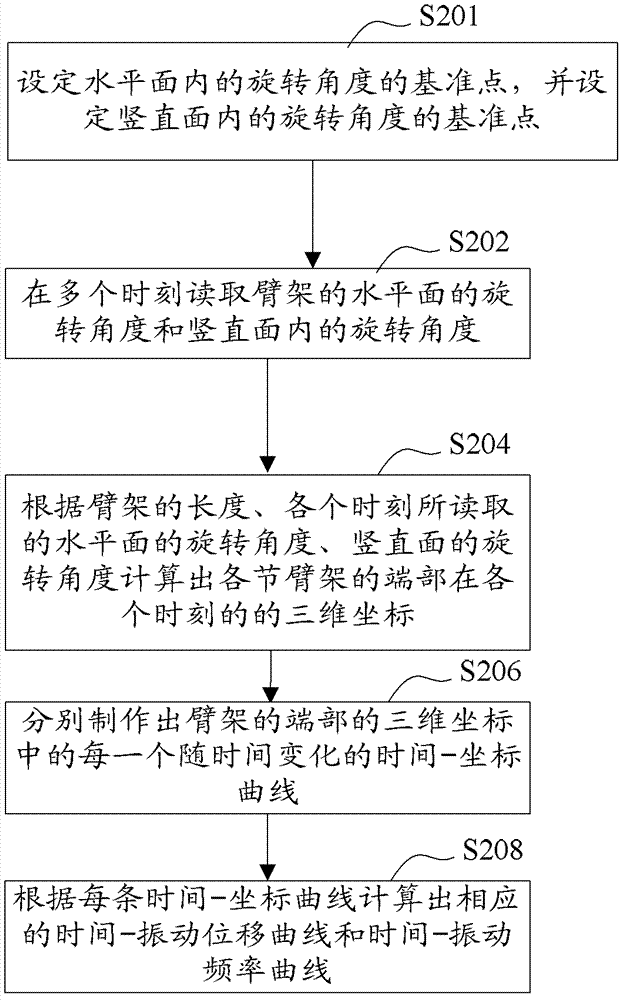

[0026] Step S102: Read the rotation angle in the horizontal plane of the jib and the rotation angle in the vertical plane of the jib at multiple times;

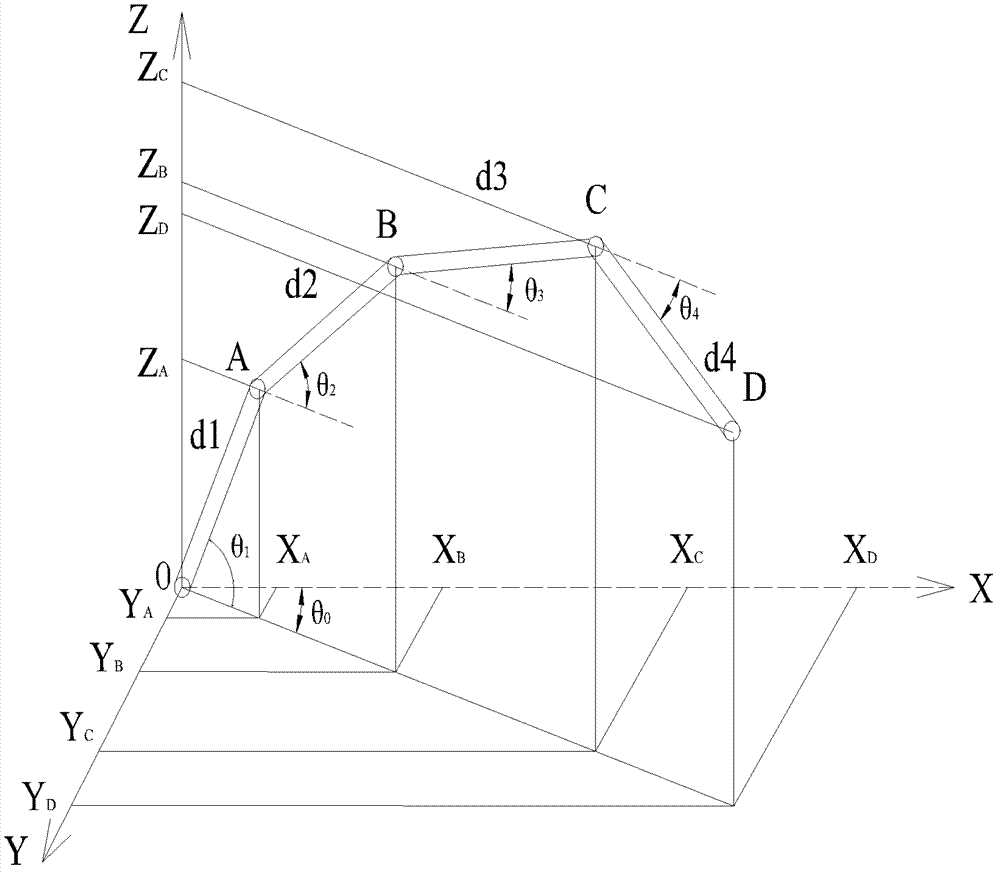

[0027] Step S104 executed thereafter: calculate the three-dimensional coordinates of the end of the boom at each moment according to the length of the boom, the rotation angle of the horizontal plane read at each moment, and the rotation angle in the vertical plane;

[0028] Step S106 to be executed afterwards: According to the calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com