Demoulding stacking machine

A stacker and demoulding technology, applied in the field of demolding stacker, can solve the problems of increased maintenance cost, neatness, poor reliability, etc., and achieves the effect of reducing maintenance cost, stacking neatly, and improving reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

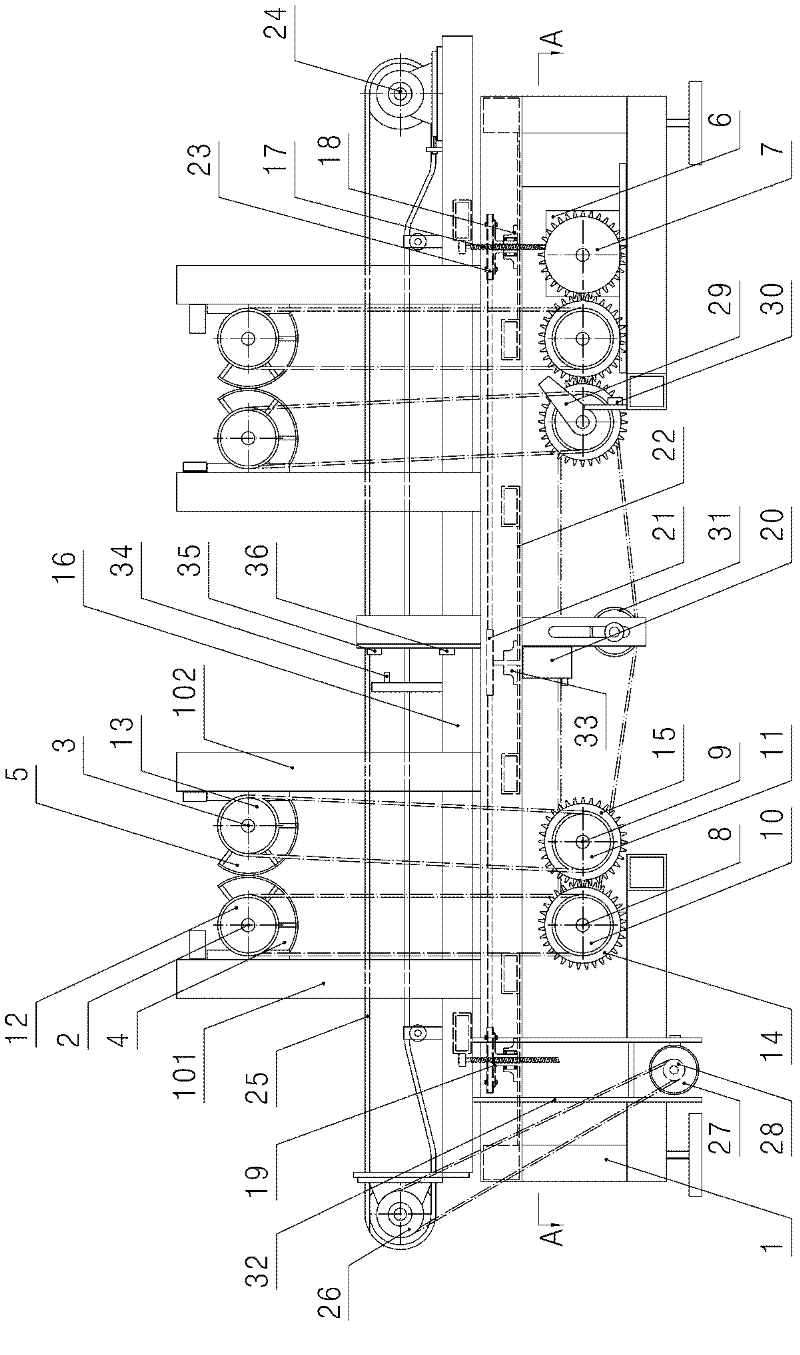

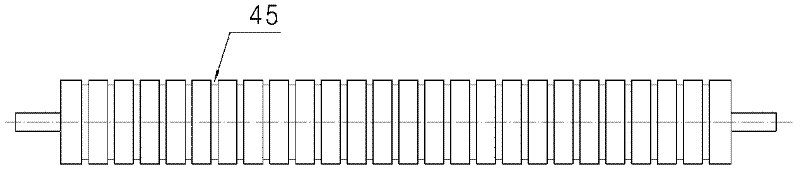

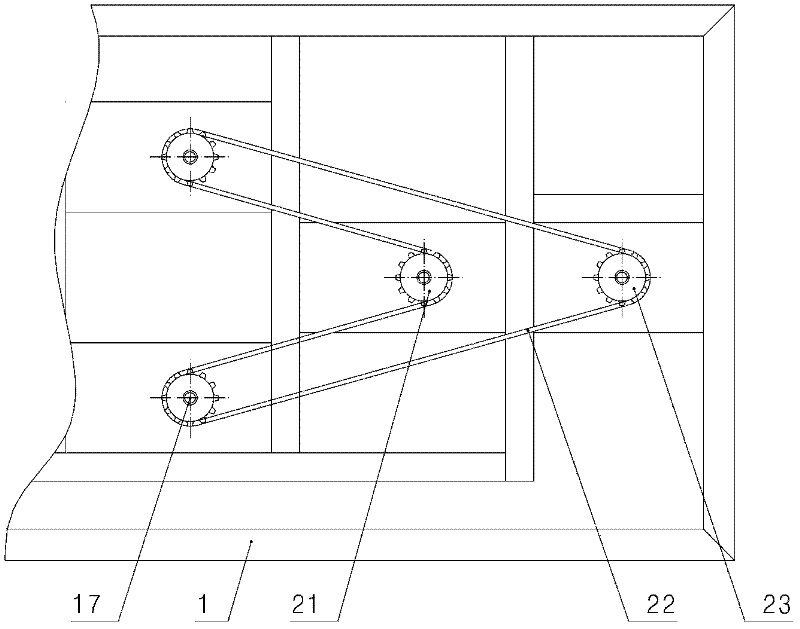

[0019] Such as figure 1 As shown, a demoulding and stacking machine according to the present invention includes: a base 1 and two sets of unloading devices arranged on the base 1, and each set of unloading devices includes: a pair of left and right brackets 101 and 102, the left support 101 is provided with a left disengagement main shaft 2, and the right support 102 is provided with a right disengagement main shaft 3 which rotates synchronously with the left disengagement main shaft 2. 3 is provided with a right unloading roller 5, and the cross-sections of the left and right unloading rollers 4 and 5 are mutually symmetrical crescent shapes (a corner is missing relative to the full moon), and one of the left and right unloading rollers 4 or 5 Several transverse grooves 45 are uniformly opened on the surface—see figure 2 As shown, each transverse groove 45 runs through the surface of the left and right unloading rollers 4 or 5; the base 1 is provided with a shaft for drivin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com