Paired film glove production line

A production line and film technology, applied in gloves, clothing, apparel, etc., can solve the problems of unpairing, discarding, waste, etc., and achieve the effect of smooth loading into the packaging box, flat and neat stacking, smooth stamping and ironing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

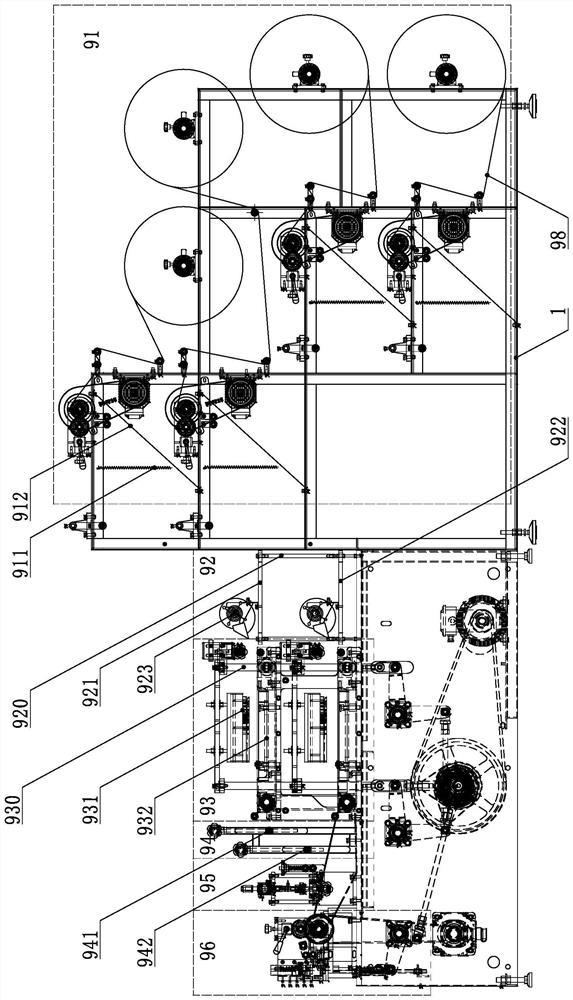

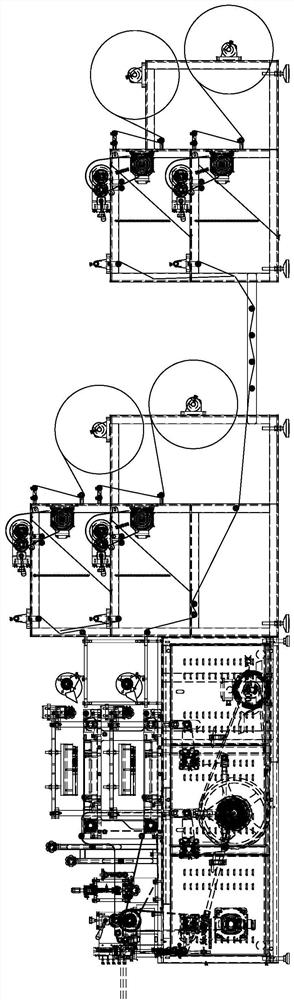

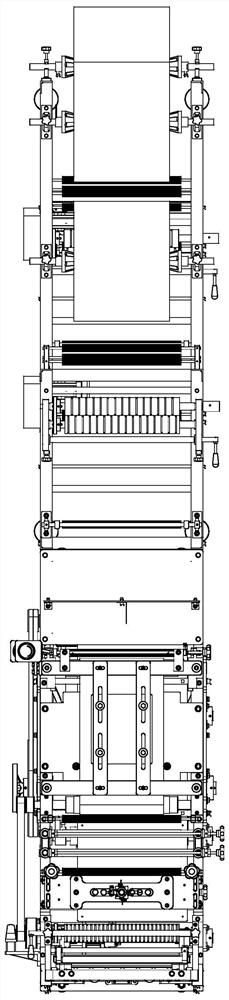

[0026] Such as figure 1 and image 3 As shown, the paired film glove production line of the present invention includes: a frame 1, on which a film discharge device 91, a material guide device 92, a glove forming device 93, a semi-finished product Guide device 94, as well as ironing and punching device 95 and glove cutting and material receiving device 96, the film traction device (belonging to the usual technology in the art, which is no longer used here) for driving film 98 to advance is also provided on the frame 1. Expand description); The film feeding device 91 includes: two double-layer film feeding units, each double-layer film feeding device includes: upper and lower film feeding mechanisms, and upper and lower two-layer film 98 are merged together and output the double-deck film merging output mechanism (belonging to the common technology in this area, no longer expand description here); Upper and lower layer film feeding mechanism are respectively provided with verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com