Spot ironing and punching device

A punching device and spot ironing technology, which is applied in metal processing, household components, household appliances, etc., can solve the problems of not being able to be neatly stacked, not paired, and waste, so as to achieve regular ironing and punching, and packaging Smooth box, stamping and ironing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

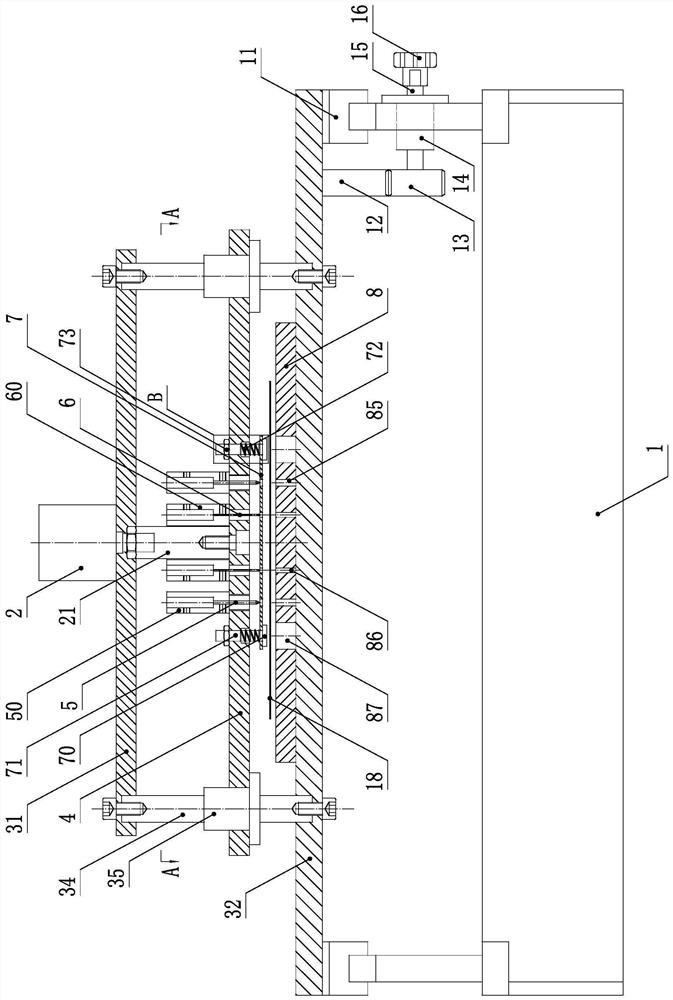

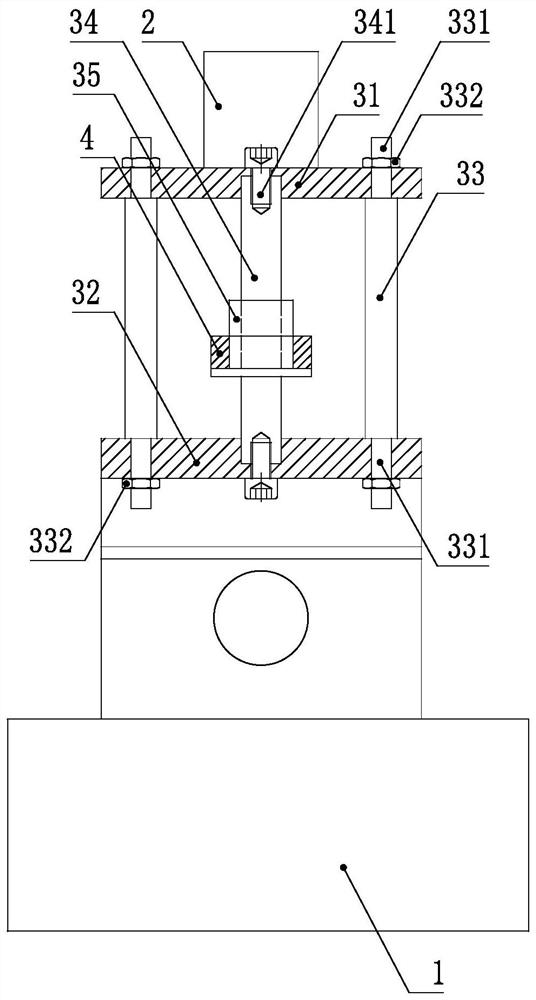

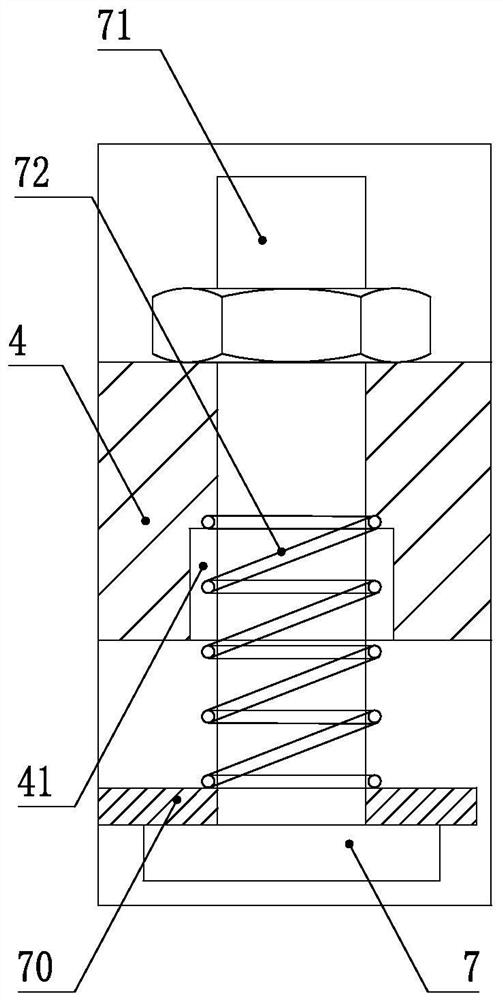

[0022] Such as figure 1 , figure 2 and Figure 4 As shown, a kind of ironing and punching device according to the present invention includes: a frame 1, on which a pair of linear bearings 11 parallel to each other is slidably provided with a lower fixing plate 32, and the lower fixing plate 32 is provided with a The mounting bracket, the specific structure of the mounting bracket includes: an upper fixing plate 31 positioned directly above the lower fixing plate 32 and parallel to the lower fixing plate 32, and four upper ends thereof are arranged in the upper fixing plate 31, The lower end is arranged on the fixed strut 33 in the lower fixed plate 32, and the upper and lower ends of the fixed strut 33 are respectively provided with a columnar extension 331 with a diameter smaller than its body, and the columnar extension 331 is provided with a threaded section. The upper and lower fixing plates 31 and 32 are provided with installation through holes that match the columnar ...

Embodiment 2

[0026] Such as Figure 5 As shown, another kind of spot ironing punching device described in the present invention, except that elastic pressing part wherein is different and needn't offer cap installation hole 87 on described working platform 8, all the other structures are identical. The elastic pressing member in the present embodiment comprises: the elastic soft pad 9 that is arranged on the back side of the slide plate 4, the elastic soft pad 9 is provided with punching pin via holes corresponding to all the punching pins 6 one-to-one, and is connected with all the thermal pads 6. Pin 5 has a one-to-one correspondence with thermal pin vias.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com