Angle piece template with adjustable angle

A technology of angle and corner fittings, applied in the direction of formwork/template/work frame, building components on-site preparation, construction, etc., which can solve the problem that the corner fitting formwork can only be used on the corner of a fixed angle value, etc. problem, to achieve a firm and reliable hinged effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

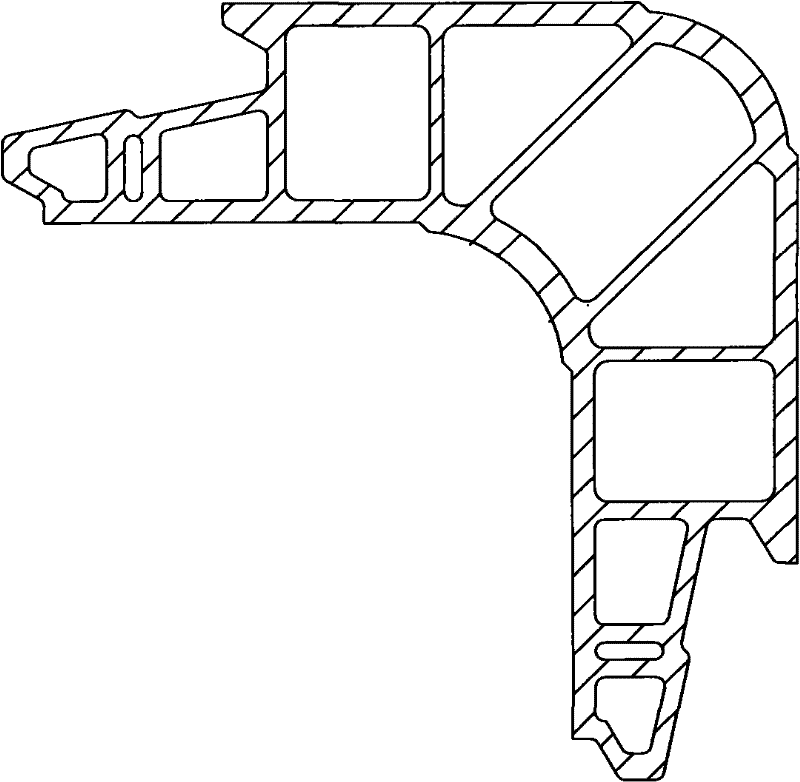

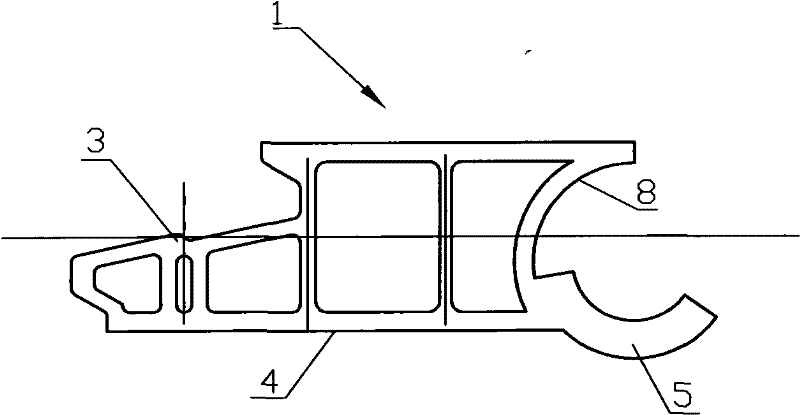

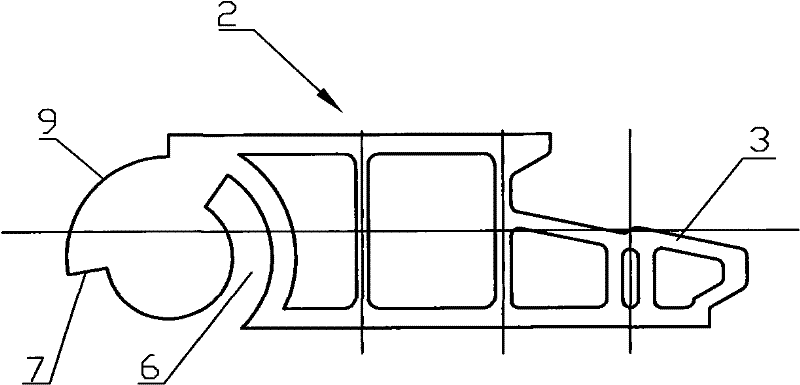

[0023] Such as Figure 2 to Figure 5 As shown, an angle-adjustable corner fitting template in this embodiment includes a first connecting arm 1 and a second connecting arm 2, and the first connecting arm 1 and the second connecting arm 2 respectively include a connecting arm body , a hinge assembly formed at one end of the connecting arm body, and a splicing joint 3 formed at the other end of the connecting arm body, which is suitable for splicing with the connecting head on the planar template, and each of the two connecting arms has A working panel 4 that participates in forming the mold cavity. When the splicing joint 3 of the connecting arm is spliced with the connecting joint of the plane template, the working panel 4 of the connecting arm is connected to the plane template. The corresponding working panels are in the same plane, wherein the hinge assembly of the first connecting arm 1 is the first hinge assembly, and the hinge assembly of the second connecting arm 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com