Gas-liquid two-phase helical flow generating device in pipeline

A technology of generating device and spiral flow, which is used in pipeline systems, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of unsolved installation problems, insignificant spiral effect, and inappropriate spiral flow. Wide application range and good spiral effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

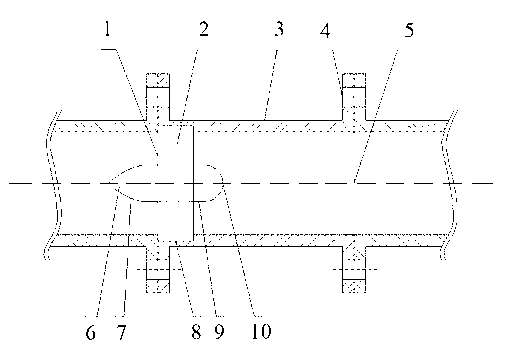

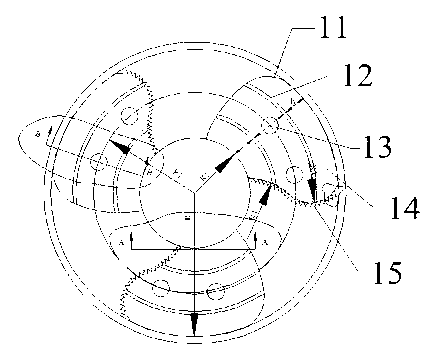

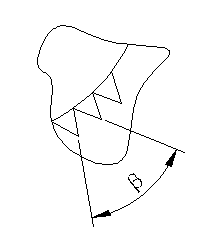

[0021] Such as figure 1 , 2 As shown, the present invention consists of the spiral flow generator 2 and the installation pipe section. The spiral flow generator includes a fixed ring 8, an impeller 11 and a guide fluid 6. The impeller 11 is composed of three identical blades 14. The fixed ring 8 and the blades 14 are connected by welding. The overall outer contour of the blade 14 is a propeller blade type , The three blades are uniformly welded on the diversion fluid at 120° intervals, such as Figure 4 As shown, the angle α between the plane of the blade 14 and the cross section of the guide fluid 6 is 20°. The vane is provided with a deflector 12, a flow hole 13 and a serrated trailing edge 15; the deflector 12 is of a circular arc shape and is evenly distributed on the blade 14 with the deflector 6 as the center. The distance h is equal, the height of the deflector 12 is 5mm, and the number of distribution on each blade 14 is 2, such as Figure 5 As shown, the angle γ betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com