Circular cone type spiral flow generator

A generator and helical flow technology, applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of low strength, difficult processing, unfavorable fixation, etc., and achieve high helical strength, good helical effect, The effect of novel structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

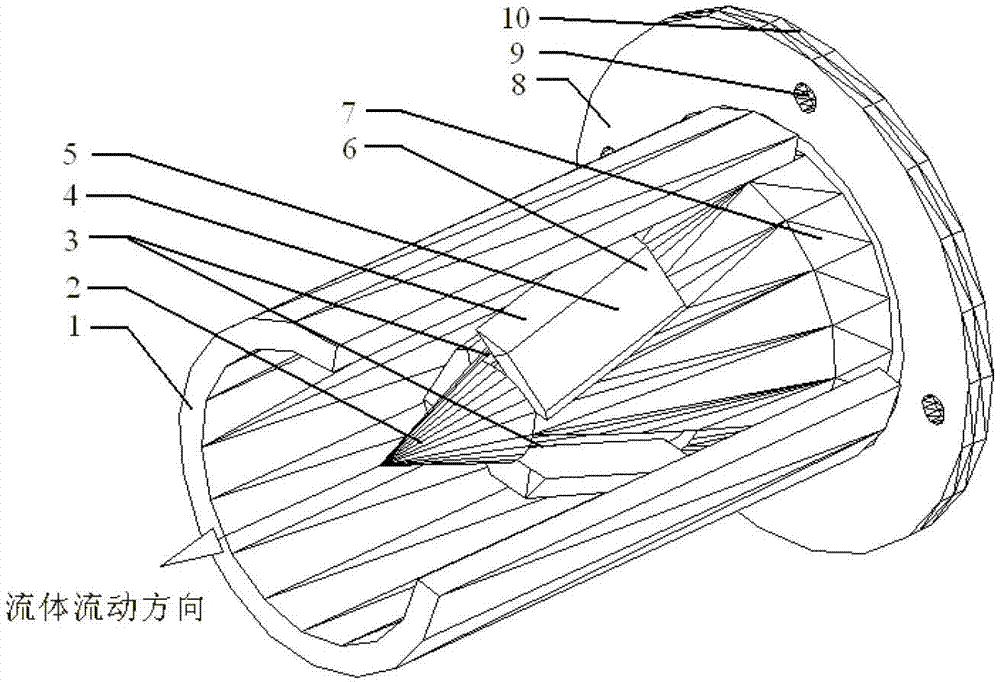

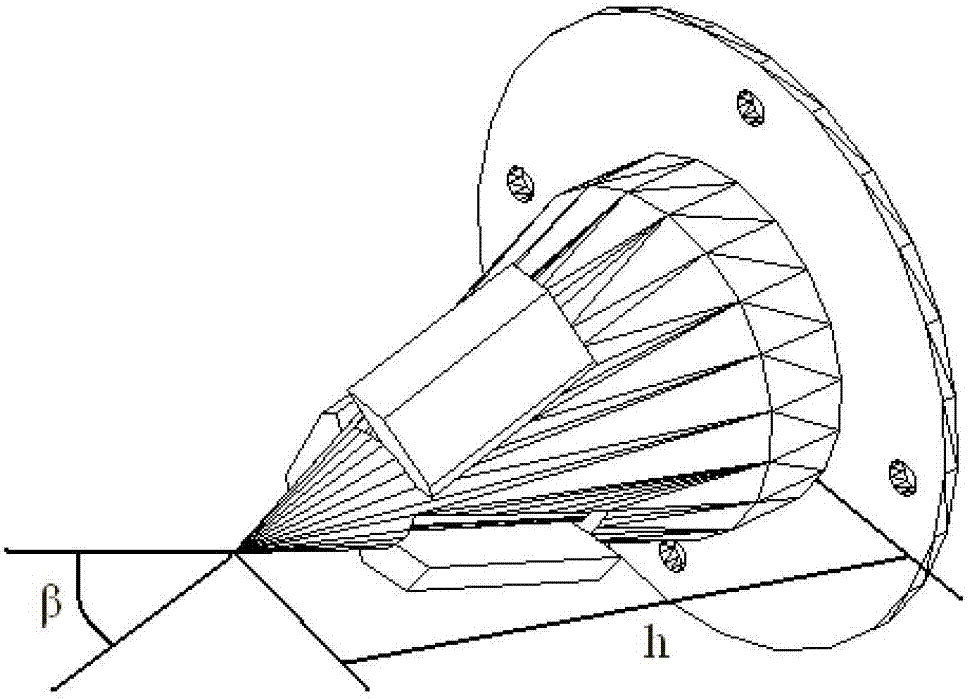

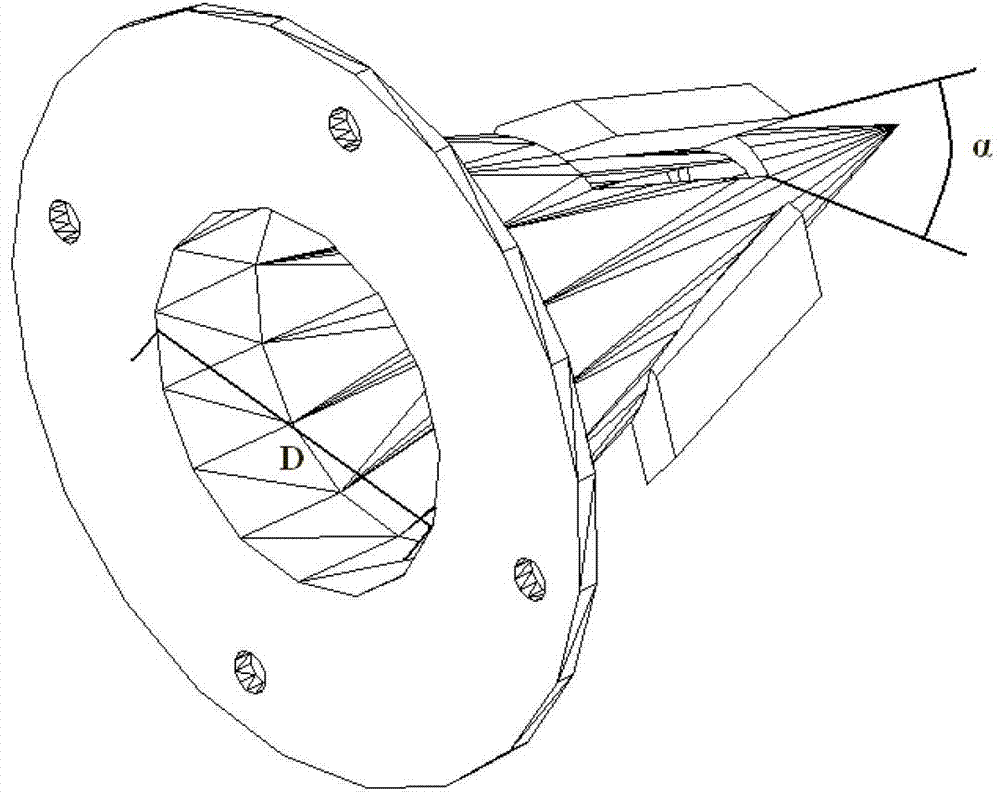

[0021] Such as figure 1 , 2 , Shown in 3, the present invention is made up of flange 10, cylinder body and fin 5 three parts. Among them, the thickness of the flange is 2 mm, and there are four evenly distributed bolt holes 9 on the surface of the flange, and the new device is firmly connected to the pipeline 1 to be connected by bolts. The barrel includes a cylindrical barrel 7 and a conical barrel 2 . Regarding the cylindrical barrel 7, the conical barrel and the flange are firmly connected by welding. The outer diameter of the barrel is the same as the inner diameter of the pipe to be connected, which is 200mm, the axial length is 50mm, and the thickness of the barrel is 2mm. Regarding the conical cylinder 2, it is one of the main components that generate the spiral flow. The inner diameter D of the bottom surface is the same as the inner diameter of the cylindrical cylinder, D=196mm, and the thickness of the conical surface of the cylinder is the same as that of the cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com