A roller comprising a drive shaft and a roller ring, as well as a method for assembling such a roller

A technology for transmission shafts and rolls, applied in the direction of rolls, shafts and bearings, metal rolling, etc., can solve the problems of weakening roll structure, harmful stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

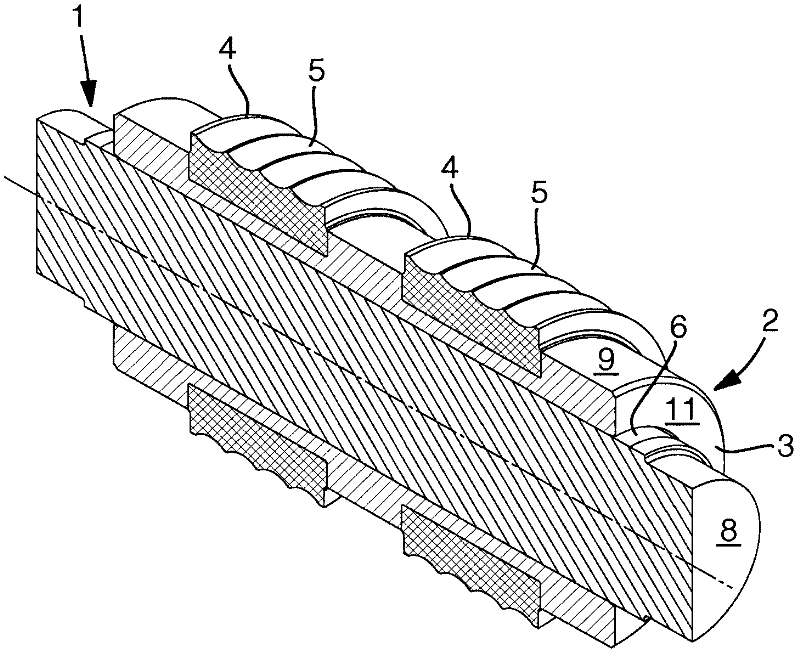

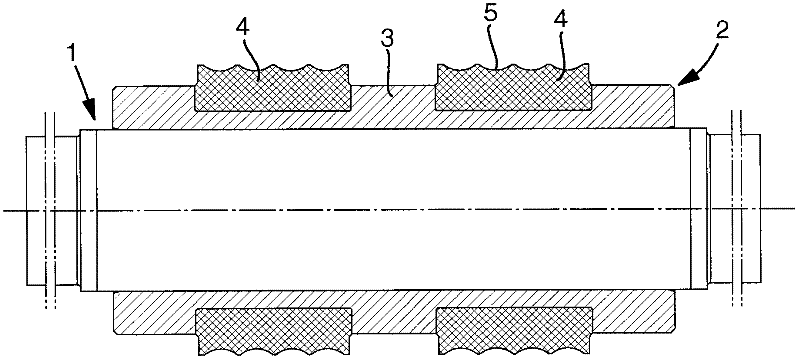

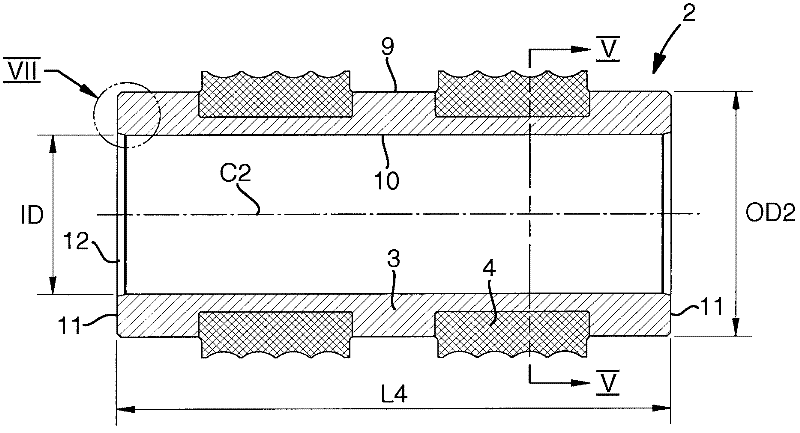

[0018] In the drawings, 1 generally denotes a roll or a drive shaft, and 2 denotes a roll ring mounted on the outside of the roll or drive shaft. In the example, said roll ring 2 comprises an inner ring 3 and two outer rings 4, in the envelope surface of which outer rings 4 are formed circumferential roll grooves 5 for rolling elongated products.

[0019] The transmission shaft 1 comprises a roller in the form of a cylindrical envelope 6 (see Figure 4 ), the roller is concentric with the central axis C1 of the shaft, and the roller transforms into an envelope surface with a journal 7 of reduced diameter at opposite ends. In this case, the ends of the shaft comprise two flat end faces 8 of journals 7 . The overall length L1 of the shaft depends on the distance between the two end faces 8 . Since each journal 7 has a certain length L2, the axial extension or length L3 of the envelope surface 6 is smaller than the overall length L1 of the shaft. The outer diameter of the shaf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com