Hot-axle alarming method for railway freight train and system

A technology for alarm systems and railway wagons, applied to railway car body components, railway vehicle shape measuring devices, railway auxiliary equipment, etc., can solve problems such as transportation interference, thermal axis misjudgment, and inconsistency, and reduce thermal axis false alarms, The effect of improving the quality of thermal axis alarm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

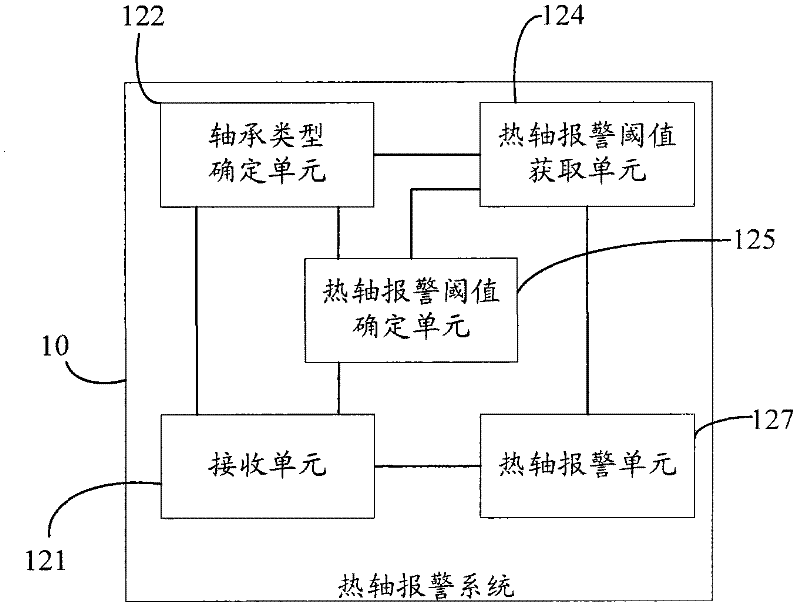

[0047] figure 1 It is a schematic structural diagram of a hot axle alarm system for railway freight cars according to an embodiment of the present invention. Such as figure 1 As shown, the hot axis alarm system 10 includes a receiving unit 121, a bearing type determination unit 122, a hot axis alarm threshold acquisition unit 124, and a hot axis alarm unit 127.

[0048] The receiving unit 121 is configured to receive the ambient temperature value of the monitored truck and the bearing temperature value detected and transmitted by the axle temperature detection system. Generally speaking, the receiving unit 121 will receive a large number of ambient temperature values and bearing temperature values periodically or irregularly transmitted by various axle temperature detection stations, and then these temperature data values will be stored in the storage unit (not shown) by the hot axle alarm system )in. Optionally, the receiving unit 121 may also directly transmit to the hot...

Embodiment 2

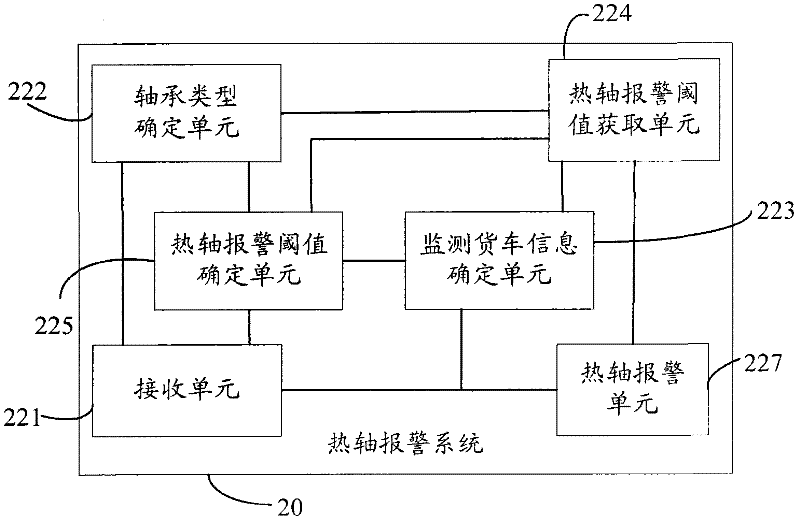

[0082] image 3 It is a schematic structural diagram of a hot axle alarm system for railway freight cars according to another embodiment of the present invention. Such as image 3 As shown, the hot axle warning system 20 includes a receiving unit 221, a bearing type determination unit 222, a monitored truck information determination unit 223, a hot axle warning threshold acquisition unit 224, and a hot axle warning unit 227.

[0083] The bearing type determination unit 222 is used to determine the type of the bearing of the monitored truck. Bearing type determination unit 221 and figure 1 The bearing type determining unit 121 in is similar, please refer to the further description of the bearing type determining unit 121.

[0084] The receiving unit 221 is configured to receive the ambient temperature value and the bearing temperature value detected and transmitted by the axle temperature detection system. Further, the bearing detection system transmits the detected temperature dat...

Embodiment 3

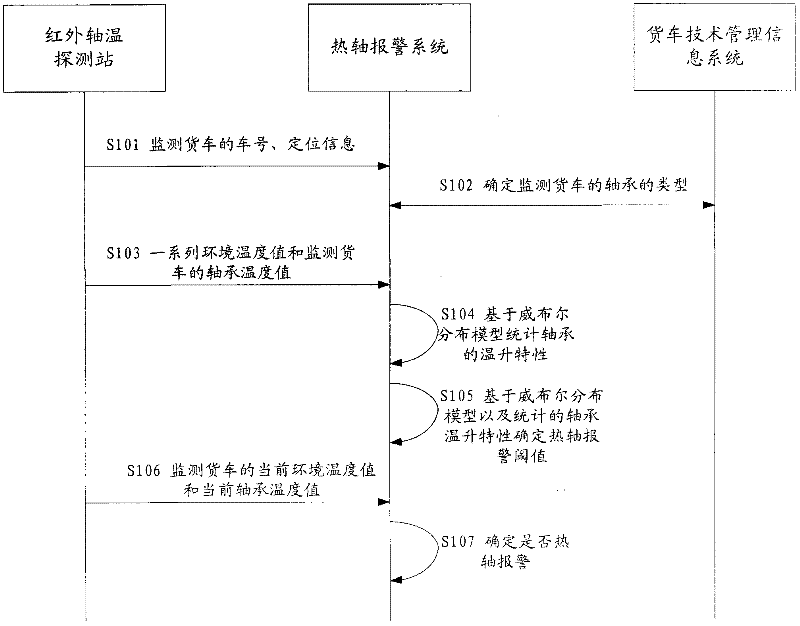

[0116] According to an embodiment of the present invention, there is also provided a hot axle warning method for railway freight cars, the method including:

[0117] 11. Determine the type of bearing for monitoring trucks;

[0118] 12. Receive the current ambient temperature value and current bearing temperature value of the monitored truck detected and transmitted by the axle temperature detection system;

[0119] 13. Find the stored hot axis alarm threshold corresponding to the bearing according to the type of the bearing;

[0120] 14 Calculate the current temperature rise of the bearing according to the current ambient temperature value and the current bearing temperature value;

[0121] 15. The current temperature rise value of the bearing is compared with the hot axis alarm threshold value, and an alarm is issued when the current temperature rise value of the bearing is greater than the hot axis alarm threshold value.

[0122] Wherein, the implementation order of the above steps is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com