Low-position coal-caving hydraulic bracket

A technology for hydraulic support and top coal caving, which is applied to mine roof supports, mining equipment, earthwork drilling, etc. Due to problems such as the large cover range of the mechanism, the effect of increasing the expansion and contraction stroke of the insert plate, the large shrinkage range and the improvement of the cover range can be achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with drawings and embodiments.

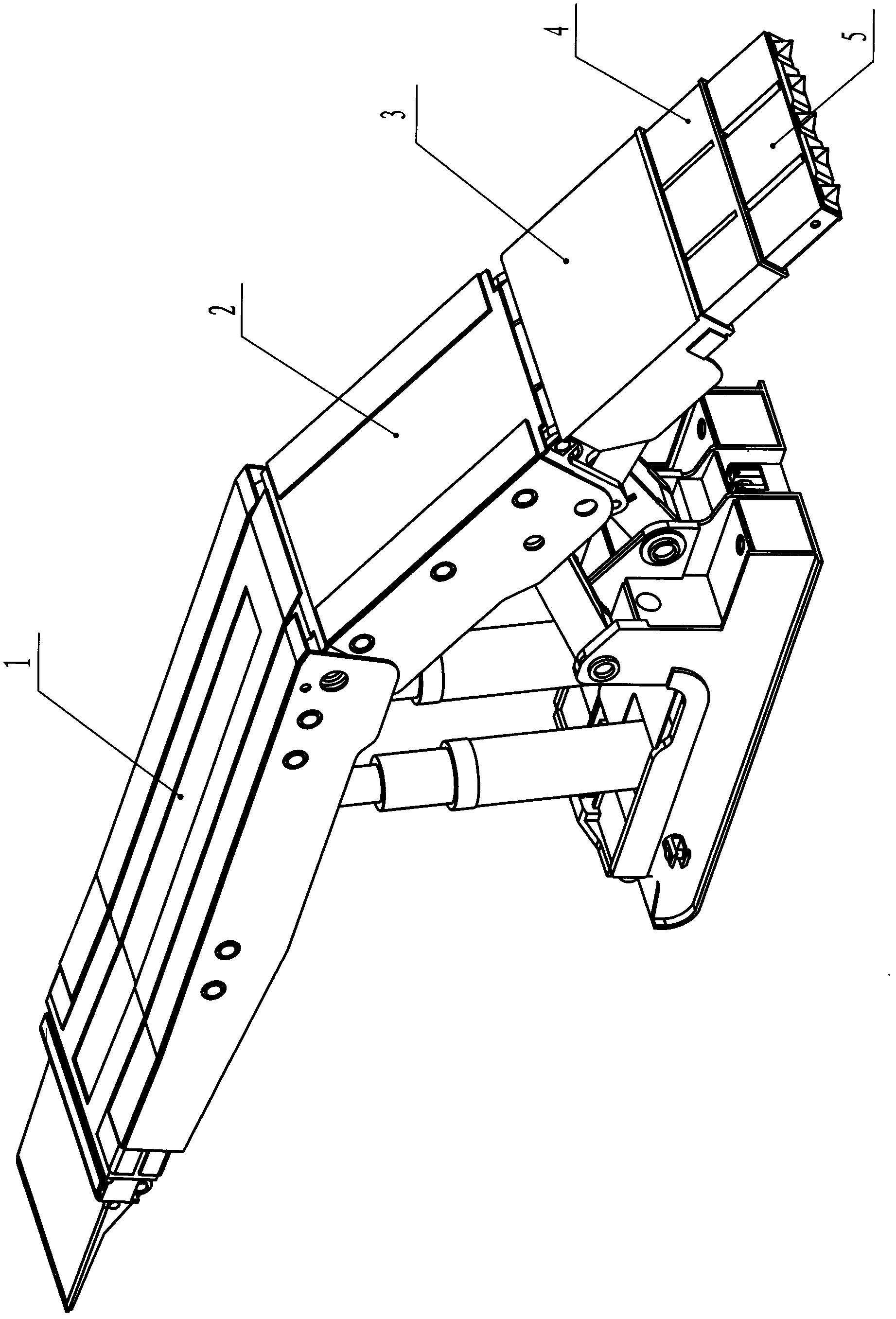

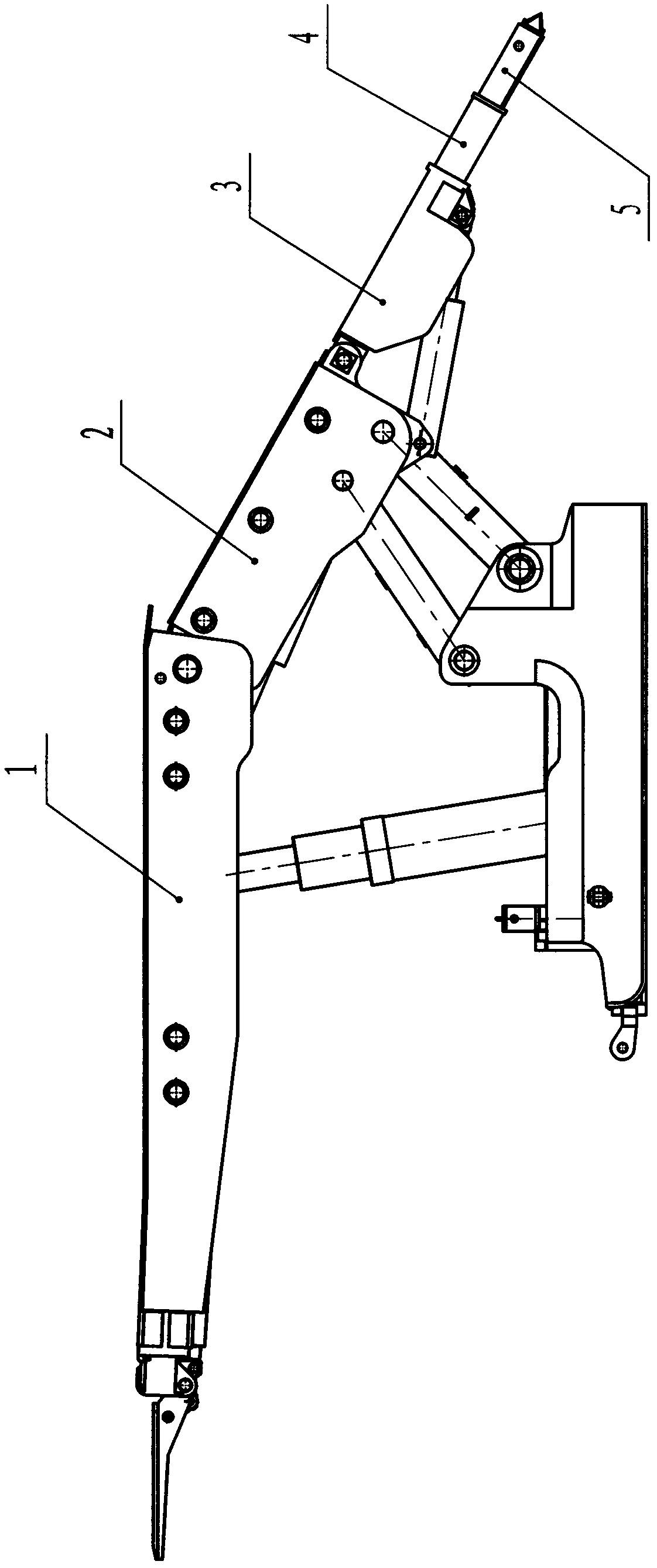

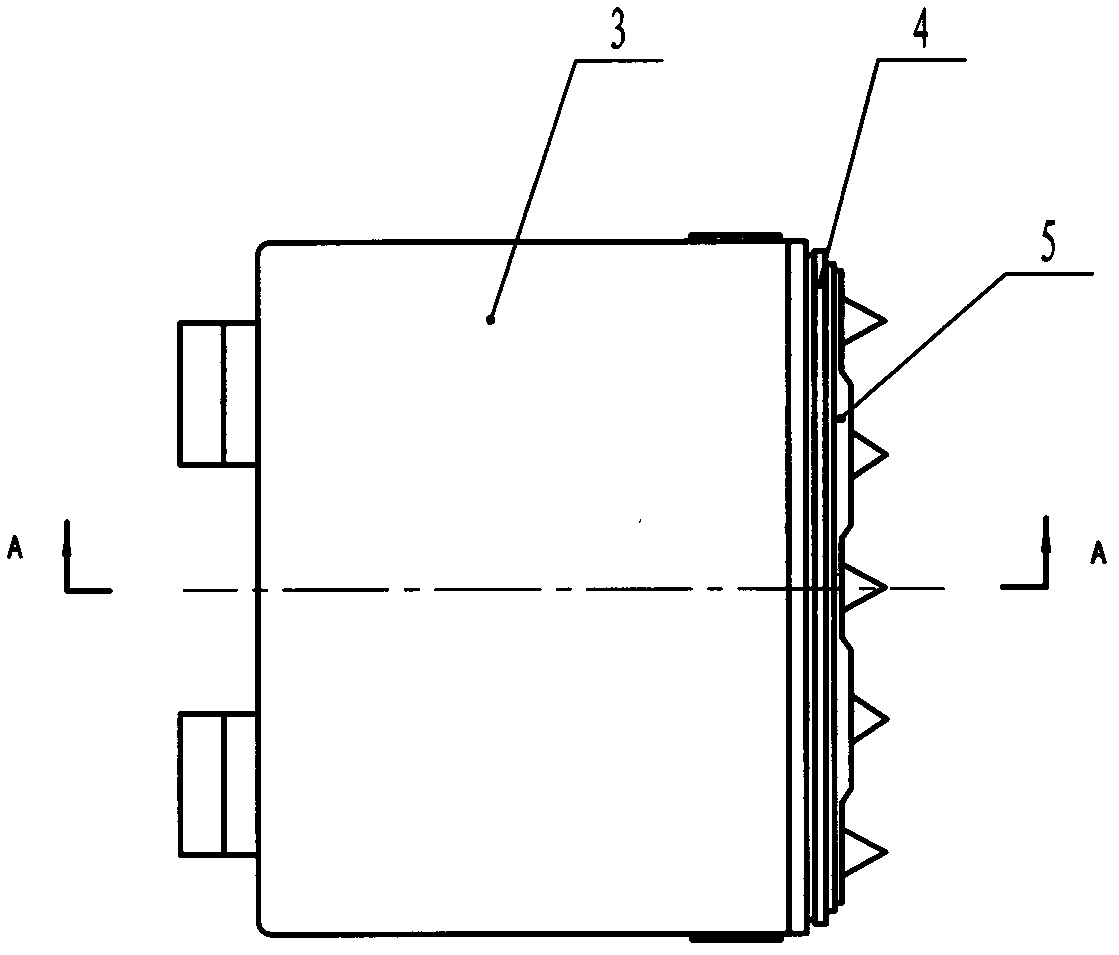

[0014] exist figure 1 , 2 The structure of the low-level top-coal caving hydraulic support of the present invention is shown in . The low-level top-coal caving hydraulic support is also called two-stage telescopic plug-in plate type and two-column low-level top-coal caving hydraulic support; it mainly consists of top beam 1, column, base, cover beam 2, four-bar linkage, and tail beam and plug-in plate Composed of coal discharge mechanism and so on. Its coal discharge mechanism is a two-stage telescopic plate-type coal discharge mechanism; The tail beam 3, the first-level insert plate 4, and the second-stage insert plate 5 are all box-shaped structures welded by steel plates; the tail beam body is provided with a slideway, and the first-stage insert plate 4 is embedded in the slideway of the tail beam body; A slideway is provided in the body of the primary board, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com