Panel module of optical disk drive

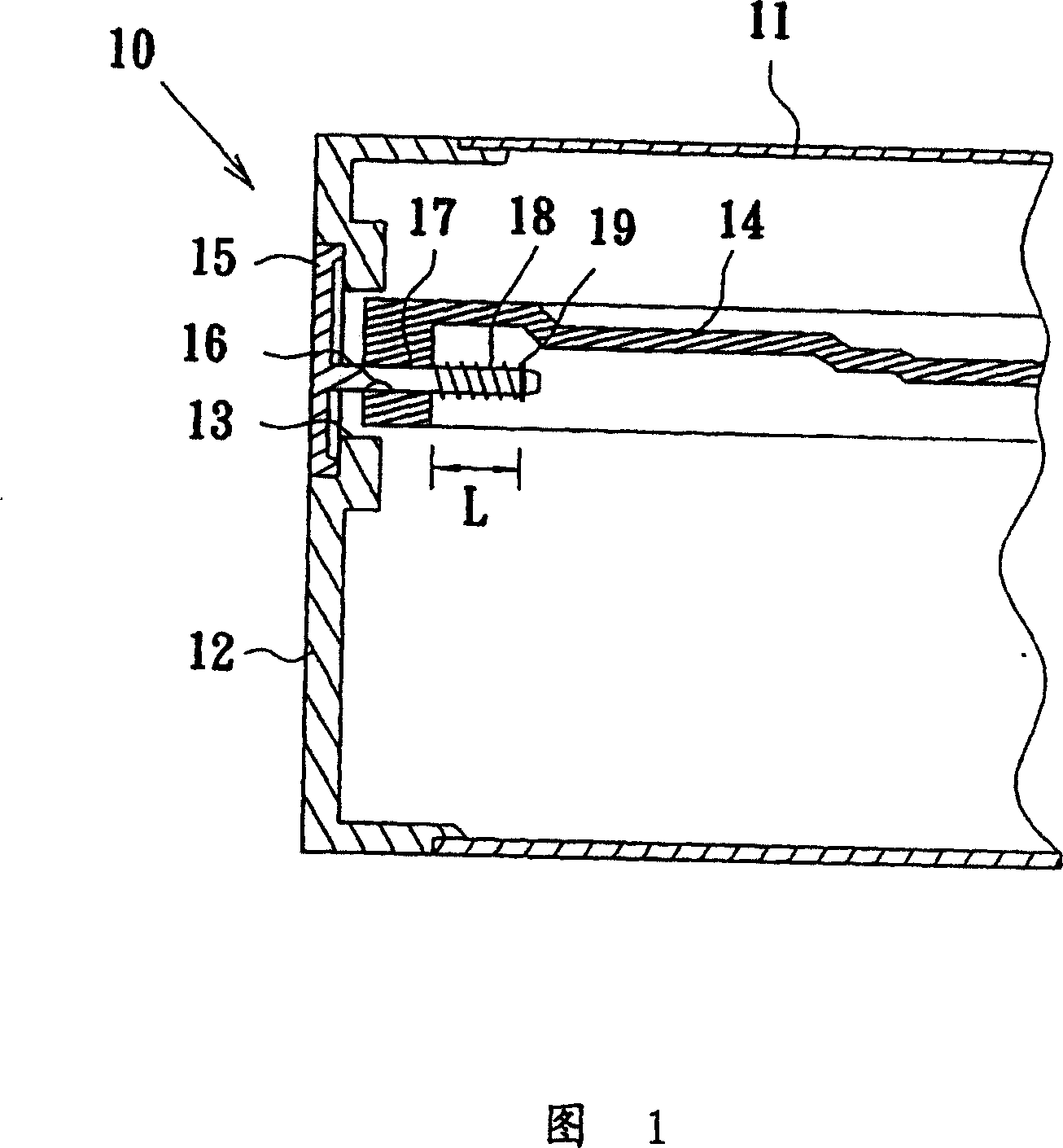

A technology for panel modules and optical disc drives, applied to instruments, record carrier structural parts, data recording, etc., can solve the problems of increasing material costs, inability to properly fit the casing 11, and reducing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

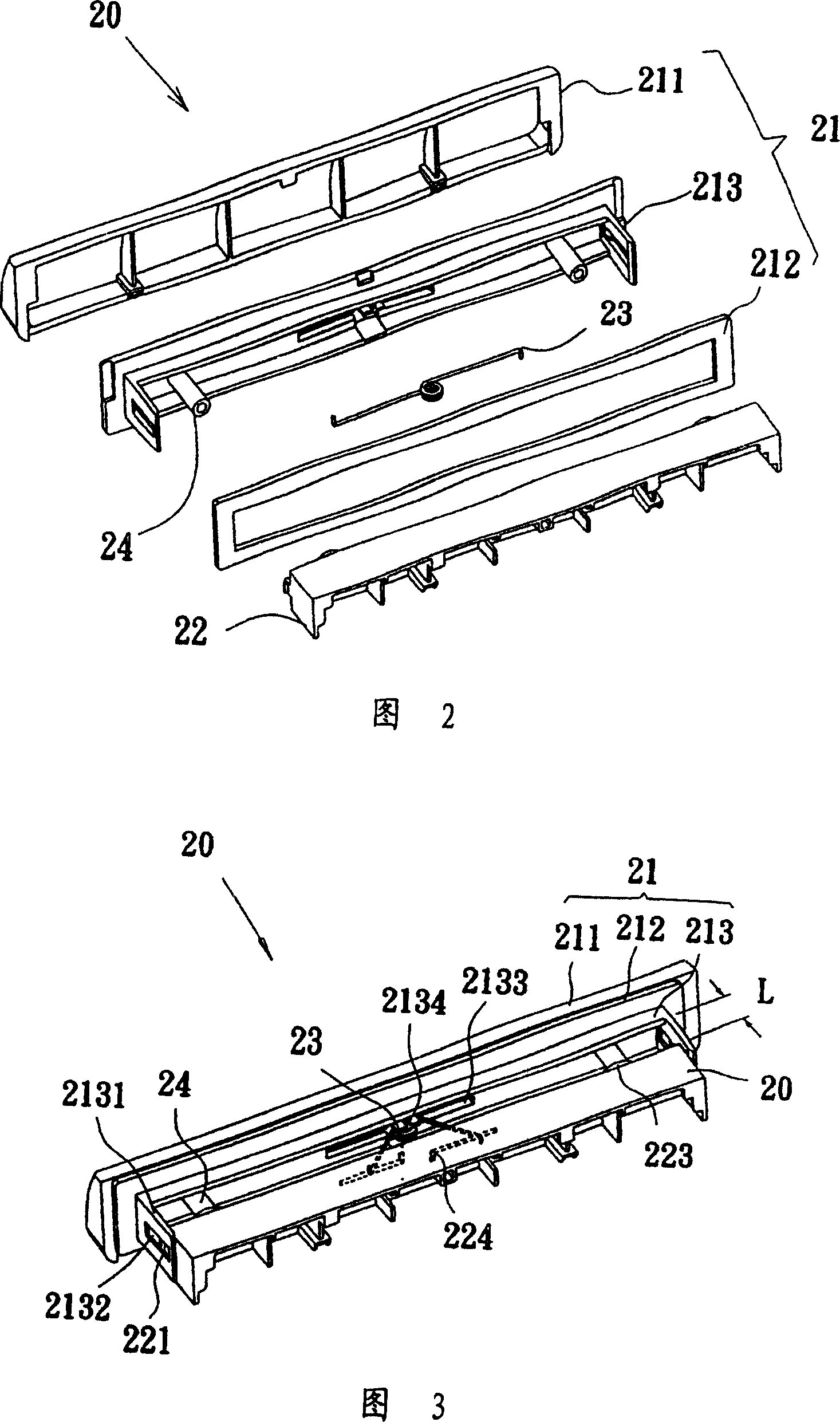

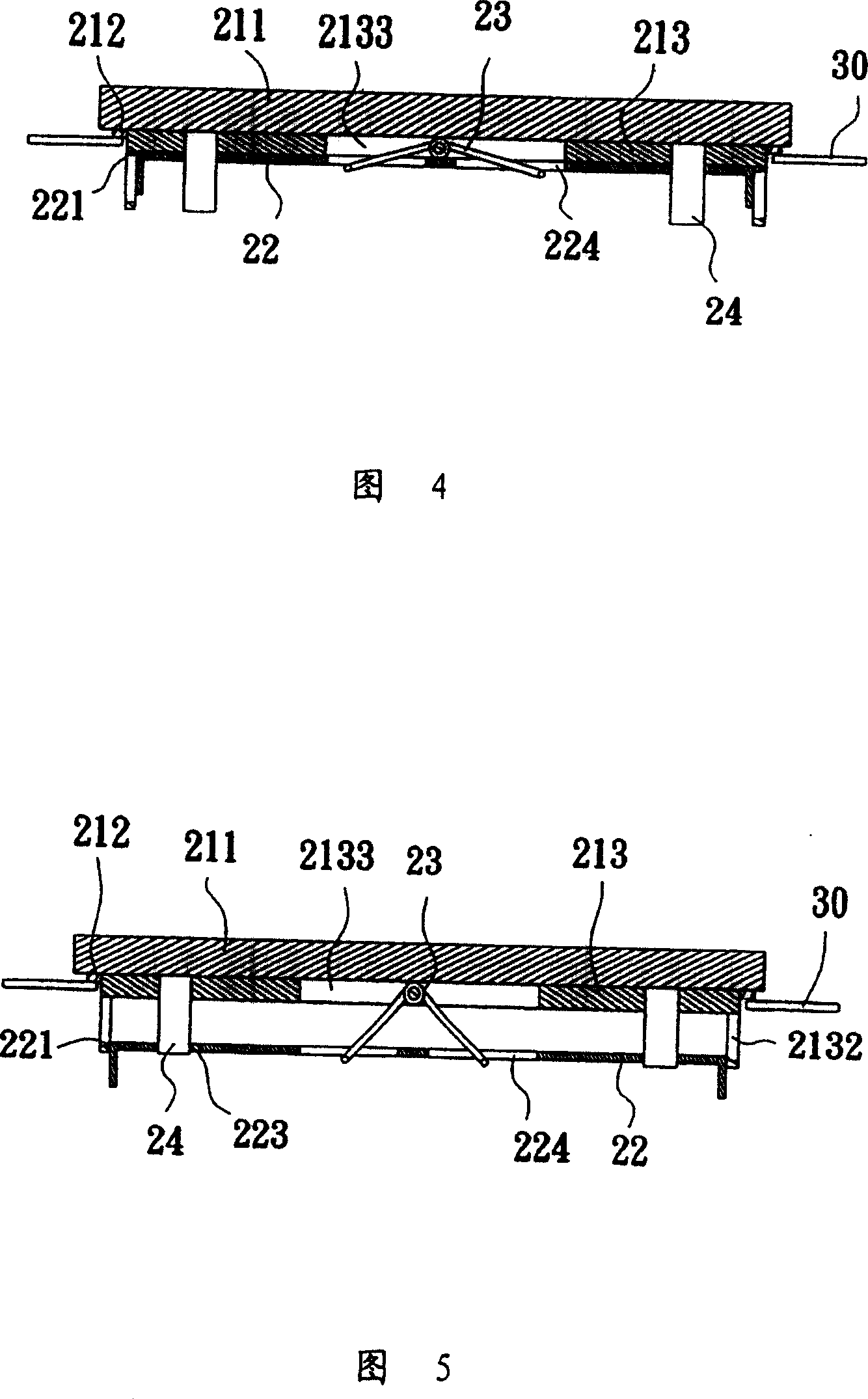

[0015] In order to achieve the above object, the present invention adopts technical means and other effects, which is a preferred embodiment, and will be described as follows in conjunction with the drawings. Please refer to FIG. 2 , the optical disc drive panel module 20 of the present invention mainly includes a panel 21 , a base 22 , a torsion spring 23 and a plurality of sliding bars 24 . The torsion spring 23 is fixed on the back of the panel 21 , and both ends are slidably connected to the base 22 , so that the base 22 moves back and forth along the slide bar 24 under the elastic force of the torsion spring 23 .

[0016] Wherein, the front panel 21 of the optical disc player panel module 20 is a decorative plate 211, the shape and style of the decorative plate 211 can be designed to meet the needs of various models of optical disc drives, and an elastic pad 212 is glued on the back of the decorative plate 211, elastic The pad 212 can be sponge, rubber or the like. A II-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com