Swinging jack control device

A technology of a control device and a jack, which is applied in the hydraulic field, can solve the problems such as the lack of the function of reflecting the numerical value of the inclination angle of the cylinder axis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

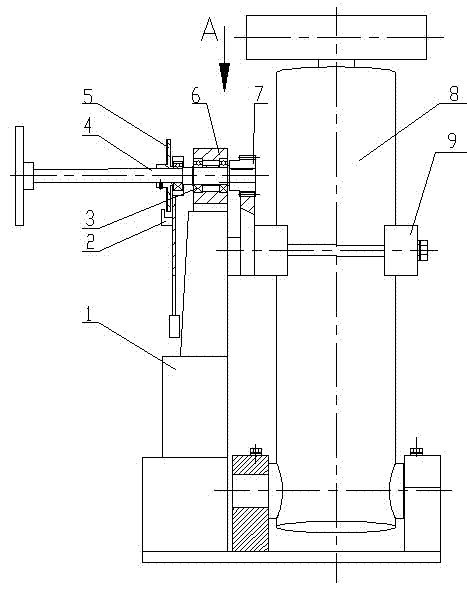

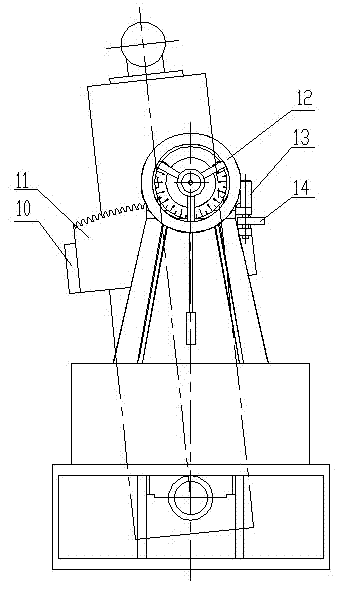

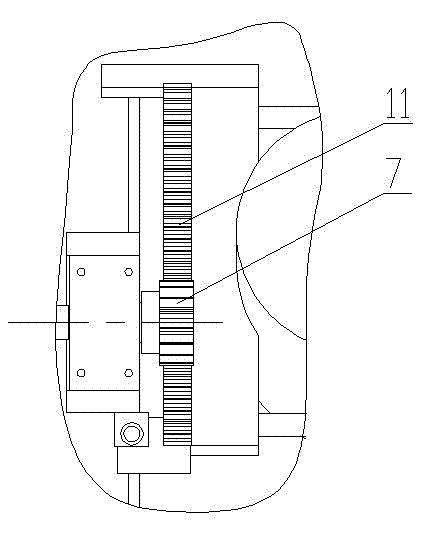

[0012] Such as figure 1 , 2 3, the swing jack control device includes a frame 1. The lower end of the frame 1 is hingedly connected to the bottom of an oil cylinder 8. The middle of the oil cylinder 8 is fixedly connected to the sector gear 11 through a fixing fixture 9, and the upper end of the frame 1 is fixedly provided with a bearing Cover 6 and bearing 3. A gear shaft 4 is inserted in the bearing 3. One end of the gear shaft 4 close to the sector gear 11 is fixedly provided with a pinion 7 meshing with the sector gear 11, and the other end of the gear shaft 4 is provided with a hand wheel 12.

[0013] The frame 1 is also provided with a left block 10 and a right block 14, and a pin 13 that can be locked with the right block 14 is fixedly arranged at a position of the sector gear 11 close to the right block 14.

[0014] A dial 5 is fixedly connected to the gear shaft 4, and a pointer 2 is movably connected to the gear shaft 4 at a position close to the dial 5.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com