Device for cleaning surface of conductor of electric wire cable

A conductor surface, wire and cable technology, used in cable/conductor manufacturing, circuits, electrical components, etc., can solve problems such as difficulty in cleaning, cable surface cleaning is ineffective, and achieve efficient and convenient cleaning, efficient and convenient conductor cleaning, and improved resistance. Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

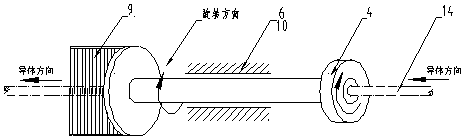

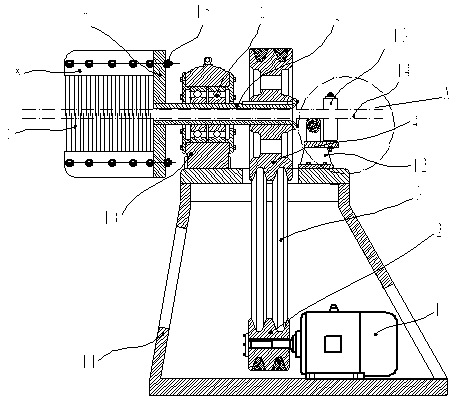

[0029] Embodiment 1: see figure 2 —4.

[0030] A wire and cable conductor surface dust and chip cleaning device: it is composed of a power transmission part, a cleaning part, a frame support frame and a support limit mechanism for wire and cable conductors; 2. It is transmitted to the passive pulley 4 through the V-belt 3. ②The cleaning part includes: the hollow rotating shaft 5 and the driven pulley 4 are connected together by a key to realize synchronous rotation; the wire and cable conductor 14 passes through the center hole of the hollow rotating shaft 5 to move in a straight line; the right end of the hollow rotating shaft 5 is provided with an adjustment fixing plate 7 and The hollow rotating shaft 5 is welded into one body, and the adjustment fixing plate 7 is provided with three oblong holes in the radial direction, which are used to fix and adjust the three brush holders 8; non-metallic brushes or non-metallic polishing objects 9 are clamped with the brush holders 8...

Embodiment 2

[0032] Example 2: see figure 2 —4.

[0033] A wire and cable conductor surface cleaning device, comprising: a frame 11, a motor 1 and a bearing seat 10 fixedly installed on the frame 11, a bearing 6 installed in the bearing seat 10, and a driving pulley fixedly connected to the output shaft of the motor 1 2. The passive pulley 4 with a central hole, the V-belt 3 sleeved on the driving pulley 2 and the passive pulley 4, also includes: the hollow rotating shaft 5 fixedly sleeved in the bearing 6 and the central hole of the passive pulley 4, and the hollow rotating shaft 5. The disc-shaped adjusting and fixing plate 7 fixedly connected at one end, the brush frame 8 connected with the disc-shaped adjusting and fixing plate 7 through the adjusting bolt 15, and the non-metallic hair brush 9 connected with the brush frame 8.

[0034] Working process is the same as embodiment 1, omitted.

Embodiment 3

[0035] Embodiment 3: see figure 2 —4.

[0036] A wire and cable conductor surface cleaning device, comprising: a frame 11, a motor 1 and a bearing seat 10 fixedly installed on the frame 11, a double-row bearing 6 installed in the bearing seat 10, and an output shaft fixedly connected to the motor 1 The driving pulley 2, the passive pulley 4 with a central hole, the V-belt 3 sleeved on the driving pulley 2 and the passive pulley 4, also includes: the hollow rotating shaft 5 fixedly sleeved in the bearing 6 and the central hole of the passive pulley 4, and The disc-shaped adjusting and fixing plate 7 fixedly connected to one end of the hollow rotating shaft 5, the brush holder 8 connected with the disc-shaped adjusting and fixing plate 7 through the adjusting bolt 15, and the non-metallic brush 9 connected with the brush holder 8;

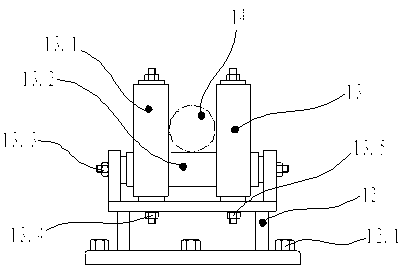

[0037] It also includes a supporting position-limiting mechanism for wire and cable conductors, the mechanism is fixedly installed on the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com