Hollow fiber ultrafiltration membrane assembly external port structure

A technology of port structure and ultrafiltration membrane, which is applied in the field of external port structure of hollow fiber ultrafiltration membrane module, which can solve the problems of inconvenient installation and disassembly, and non-repeatable disassembly of bonding ports, so as to save assembly and disassembly time and facilitate installation and disassembly and fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with the drawings and specific embodiments, but the protection scope of the present invention is not limited to the embodiments.

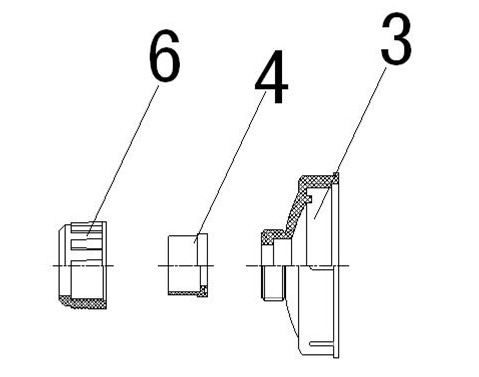

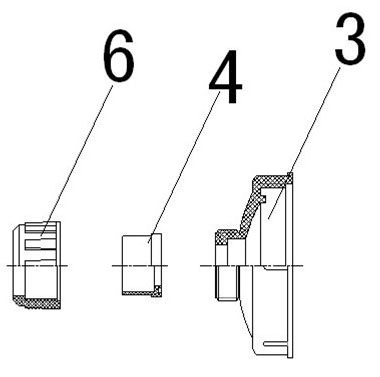

[0008] as attached figure 1 As shown, the present invention provides an external port structure of a hollow fiber ultrafiltration membrane module, including a hollow fiber ultrafiltration membrane module and an external port part, and the external port part includes a port, a port connector and a fastening part.

[0009] Compared with the existing technology, due to the detachable joint structure at the interface, the external water pipe and the hollow fiber ultrafiltration membrane module can be repeatedly installed and disassembled at any time. Compared with the existing port connection, the work efficiency is greatly improved. Great improvement, saving workers a lot of time when installing or repairing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com