Slope positioner

A positioner and slope technology, applied in auxiliary devices, high-frequency current welding equipment, auxiliary welding equipment, etc., can solve the problems of restricting the use of the scope of activity, difficult to adapt to the efficiency of positioning, and inconvenient to use and operate. Reasonable design, ingenious conception, and the effect of improving work efficiency

Inactive Publication Date: 2012-03-14

杨清福

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] The existing combined frame body for positioning is extremely inconvenient to use and operate. The positioning structure of this structure is simple, which still restricts the utilization of the range of motion used. Therefore, it is difficult to adapt to positioning without changing the structure of the positioning frame. efficiency

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

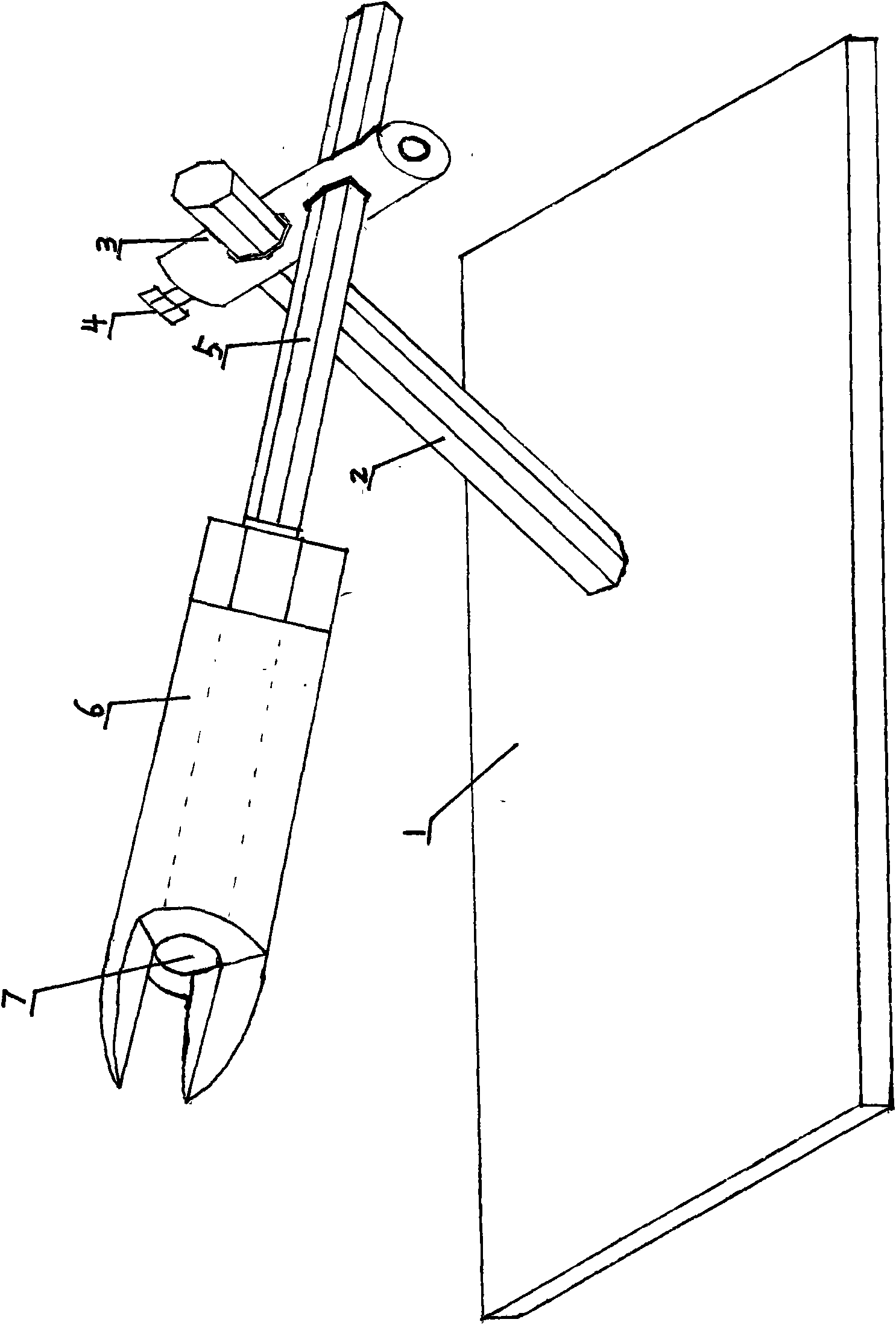

[0007] A positioner for inclination, comprising a rectangular base 1, on which an oblique support hexagonal rod 2 is fixed, on the hexagonal rod 2 there is a sleeve 3 with cross vertical holes for sliding positioning, and the sleeve 3 has There are locking bolts 4, and the inner hole of the sleeve type part 3 has a sliding rod 5, which is movably connected with the rotating part 6, and the end is a component placement hole 7.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a high-frequency welding device, in particular to mutual fixation between components, and particularly to a slope positioner. The slope positioner comprises a rectangular substrate on which a hexagonal sloped support rod is fastened; a sleeve component with vertical crossed holes for sliding and positioning is disposed on the hexagonal rod; the sleeve component has a lock bolt; the inner hole of the sleeve component is provided with a sliding rod and moveably connected with a rotating piece; and component accommodating holes are arranged at the ends. The slope positioner is rational in design and smart in design; by using the principle of sleeve rail movement of a support body, the slope positioner is capable of moving up and down, and moving forwards and backwards, namely, the slope positioner is adapted to the positioning requirement of a high-frequency welding component; and the working efficiency of the slope positioner is greatly increased.

Description

technical field [0001] The invention relates to a high-frequency welding device, in particular to the mutual fixing of components, in particular to a slope positioner. Background technique [0002] The existing combined frame body for positioning is extremely inconvenient to use and operate. The positioning structure of this structure is simple, which still restricts the utilization of the range of motion used. Therefore, it is difficult to adapt to positioning without changing the structure of the positioning frame. efficiency. Contents of the invention [0003] In order to further improve the working efficiency of the positioning frame during component welding, the present invention provides a slope positioner. [0004] In order to achieve the above object, the present invention adopts the following technical solutions: an inclination positioner, including a rectangular base, on which an oblique support hexagonal rod is fixed, and the hexagonal rod has a set of cross ve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K37/04B23K13/00

Inventor 杨清福

Owner 杨清福

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com