60L inner bag compound container and liquid medicine discharge pipe

A composite container and discharge pipe technology, applied in containers, rigid containers, harmful substances packaging, etc., can solve the problems of imposition, expensive liquid medicine, complicated operations, etc., and achieve the goal of realizing residual liquid volume, complicated operations and improving workability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

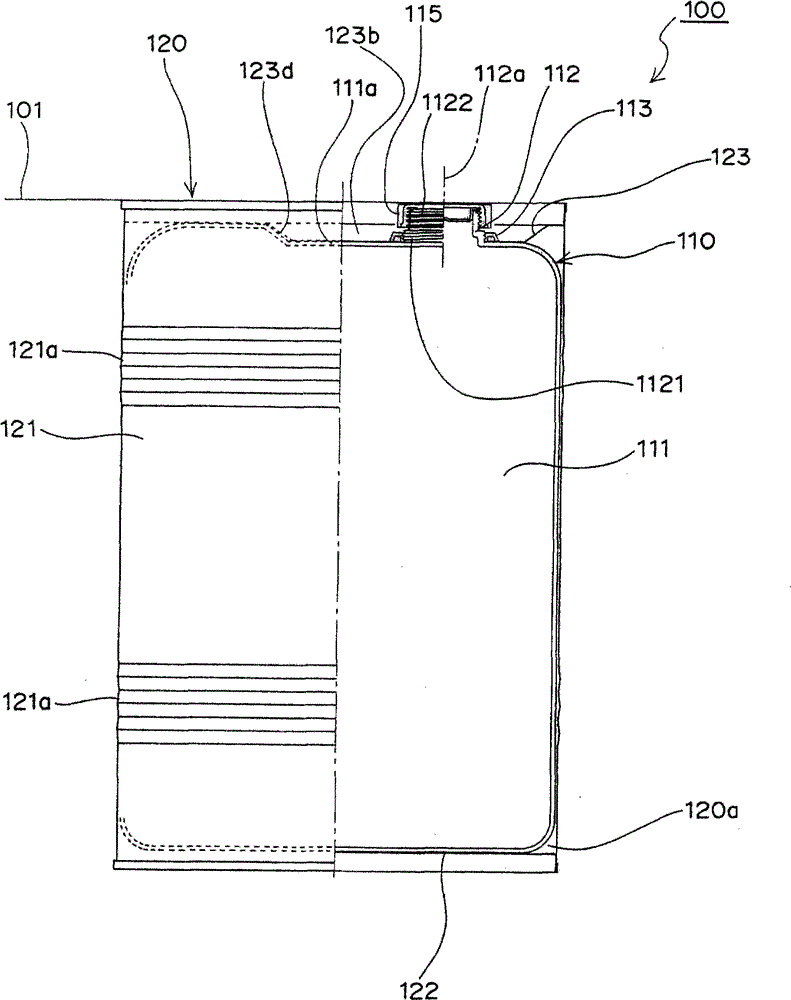

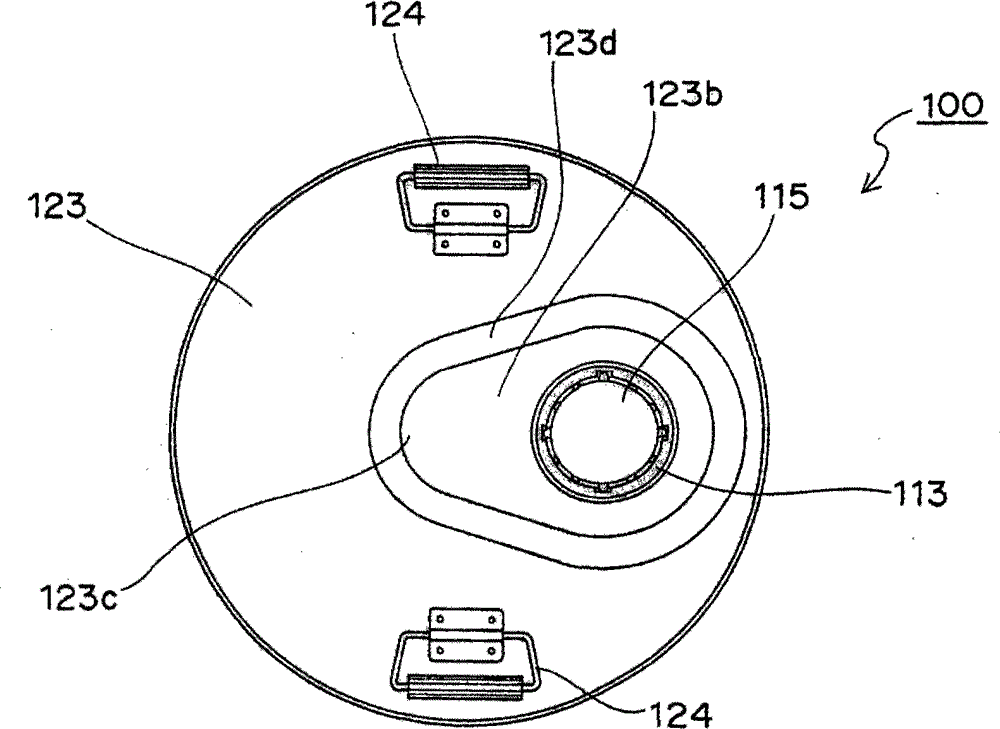

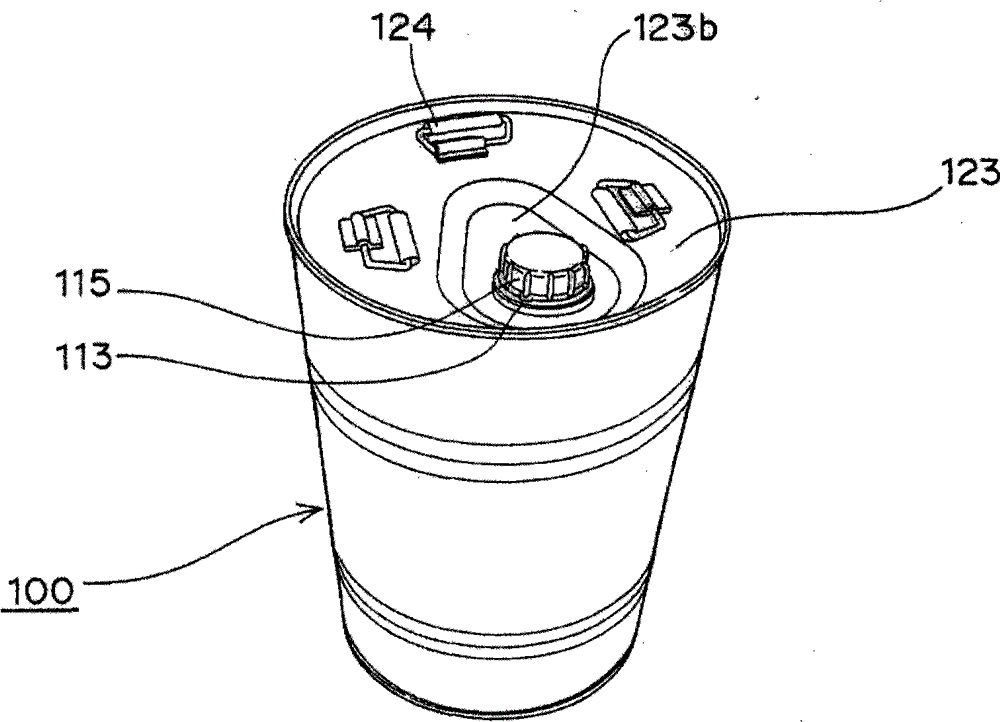

[0058] Hereinafter, a 60-liter inner bag composite container according to an embodiment of the present invention will be described with reference to the drawings. In addition, the same code|symbol is attached|subjected to the same or equivalent component in each drawing.

[0059] Figure 1 to Figure 4 In the figure, the structure of the 60 liter inner bag composite container 100 of this embodiment is shown. The 60-liter inner bag composite container 100 has a resin inner container 110 and a steel outer container 120 for accommodating the inner container 110 as in the conventional 20-liter inner bag composite container.

[0060] The main body 111 of the inner container 110 is made of high-density polyethylene resin, and is blow-molded into a bag shape, and its capacity is 60 liters. The liquid inlet and outlet part 112 that allows the liquid medicine to enter and exit. The liquid inlet and outlet part 112 can be molded simultaneously with the blow molding of the main body pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com