Detonation-driving shock tunnel explosive discharge device

A shock wave wind tunnel and detonation technology, which is used in measurement devices, aerodynamic tests, instruments, etc., can solve the problems of reducing the driving gas pressure and affecting the wind tunnel test time, and achieve the effect of increasing the test time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

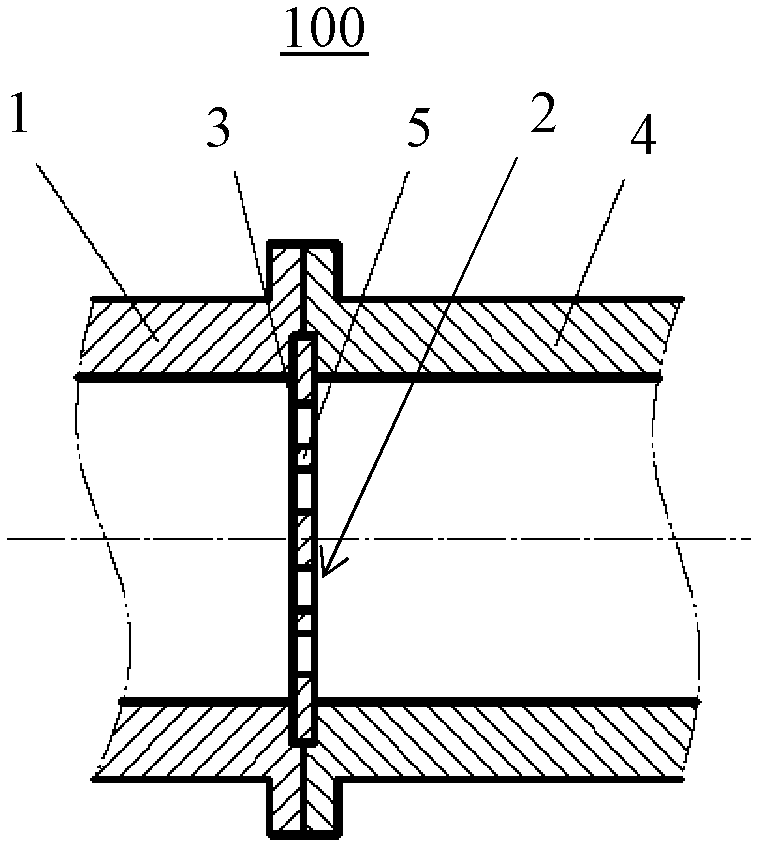

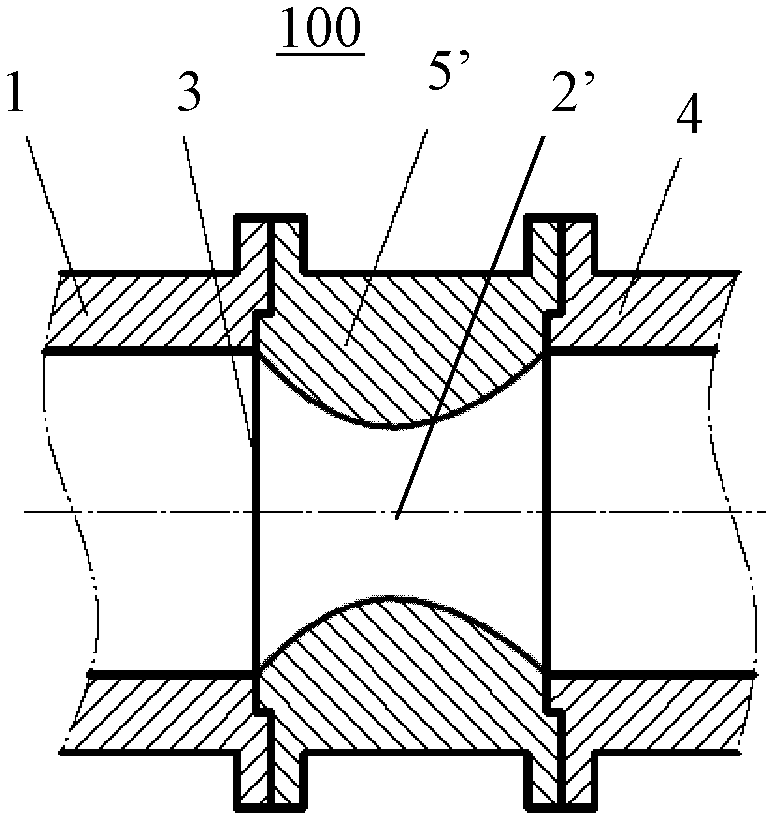

[0013] figure 1 It is a structural schematic diagram of an embodiment of the detonation-driven shock tunnel detonation device of the present invention.

[0014] Such as figure 1 As shown, the present invention comprises: shock wave wind tunnel 100, and this shock wave wind tunnel 100 comprises detonation driving section 4 and unloading section 1, and a detonation throttling is installed between detonation driving section 4 and unloading section 1 The device is used to adjust the flow rate of the high-pressure air flow formed in the detonation driving section 4 into the detonation section 1, and a diaphragm 3 is also arranged on the side of the detonation throttling device close to the detonation section 1.

[0015] Such as figure 1 As shown, one embodiment of the detonation and throttling device of the present invention is to adopt a plate 2 with a certain thickness. A certain number of through holes 5 are opened in the thickness direction of the board 2 . The quantity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com