Optical sheet with laminated double-sided light guide plate

A technology of optical sheets and light guide plates, applied in the field of optical sheets, can solve problems such as limited single-sided light guide plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

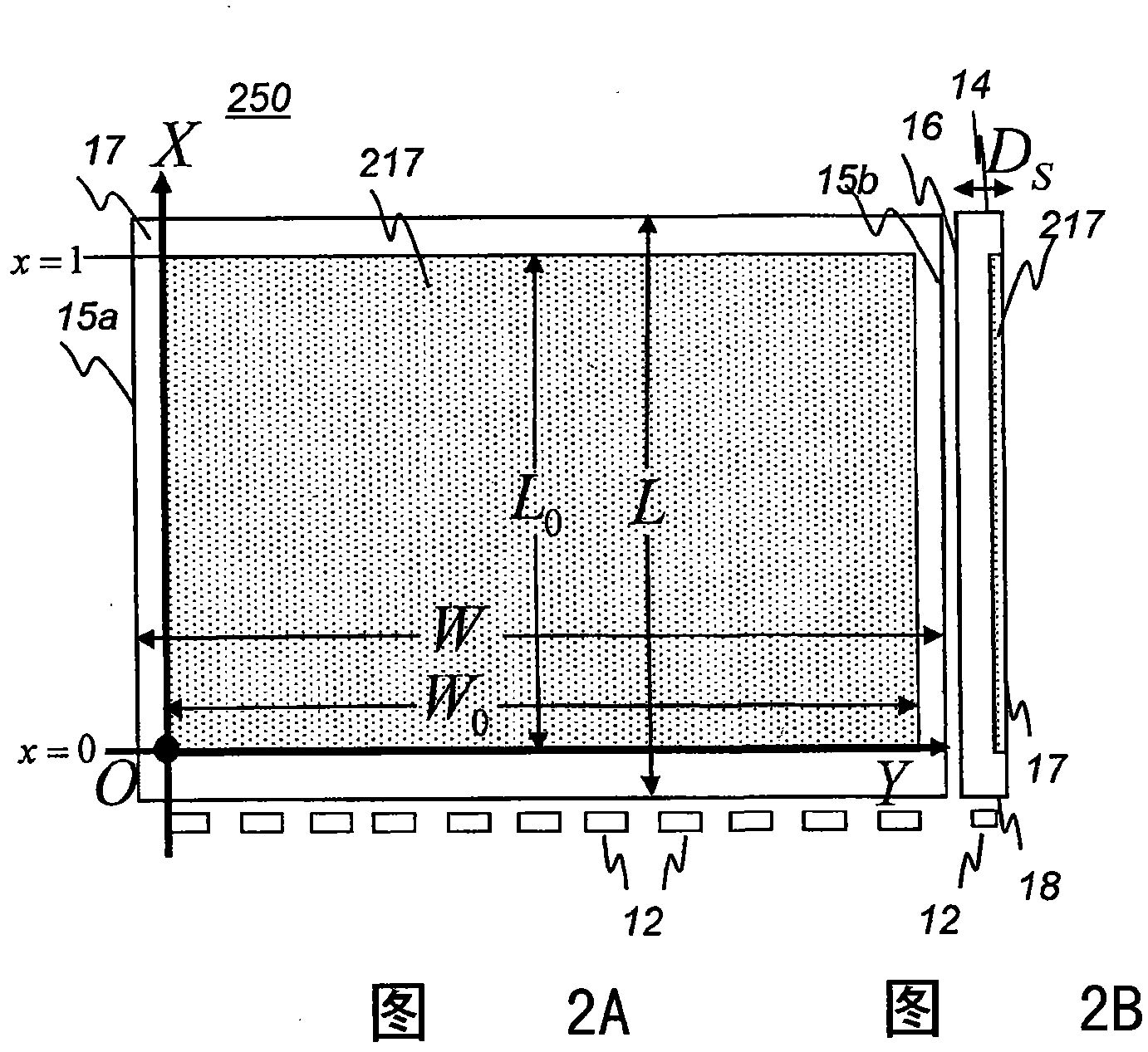

[0070] The optical sheet 300 has a length Ls≈957mm, a width Ws≈343mm, and a thickness Ds ranging from 0.1mm to 0.7mm. There are four light guide plate patterns on the optical sheet 300, each having the same length varying between 150mm to 240mm and width varying between 150mm to 320mm. Since all four light guide plates were produced together in a roll-to-roll process, each light guide plate was produced within 1 second at a processing line speed of 250 mm per second. It is conceivable that for a large number of small light guide plates on the same optical sheet 300 and the same patterned roller, for example, the length and width dimensions are about 20mm, and at the same processing line speed, each light guide plate produced requires The time will be shorter.

Embodiment 2

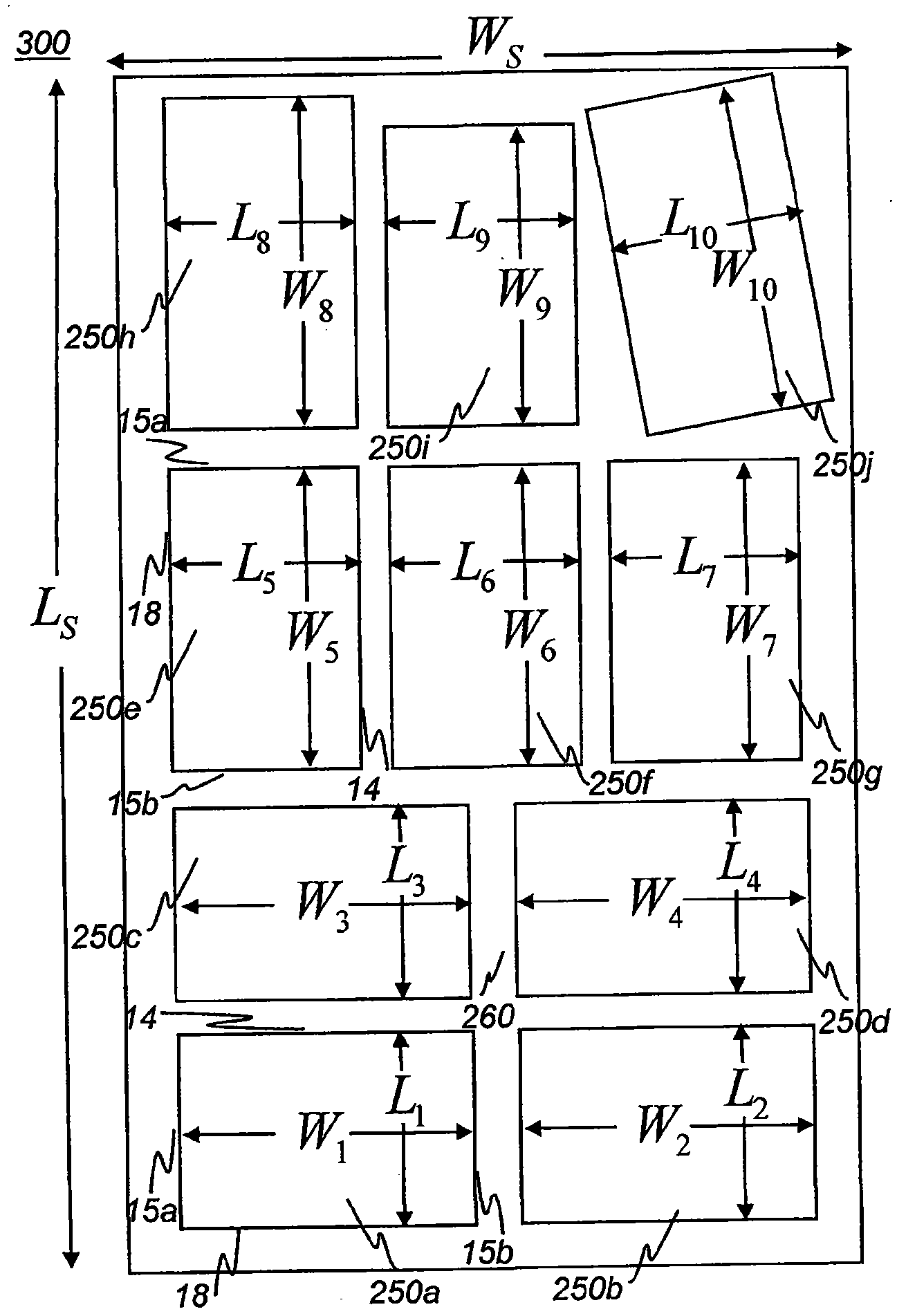

[0072] The optical sheet 300 has a length Ls≈1436mm, a width Ws≈686mm, and a thickness Ds ranging from 0.1mm to 0.7mm. There are 14 light guide plate patterns on the optical sheet 300, each of which has the same length varying from 150mm to 240mm and width varying from 150mm to 320mm.

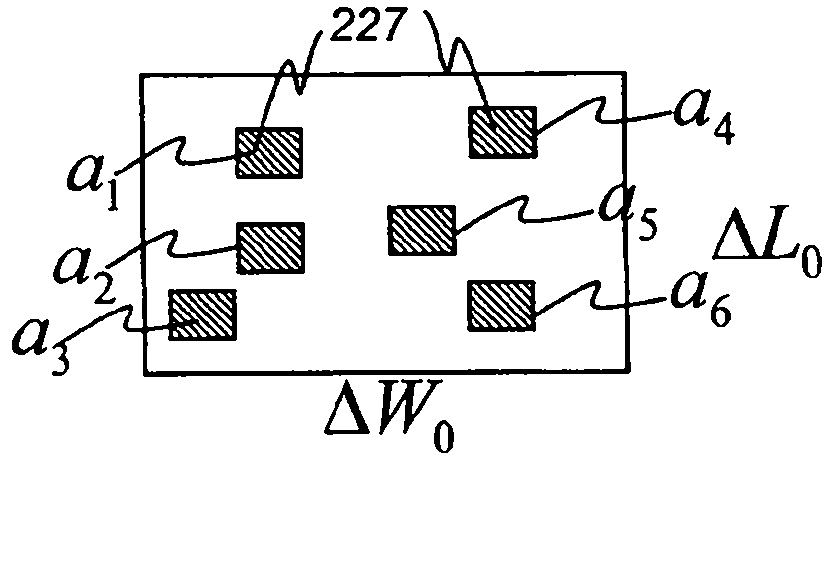

[0073] The above 14 light guide plate patterns have one or more of the following features. In one aspect, at least two of the 14 light guides have different lengths. In another aspect, at least two of the 14 light guide plates have different widths. On the other hand, at least one of the 14 light guide plates has the same width direction as the optical sheet 300 . E.g, figure 1 The light guide plate 250a is shown with W 1 Indicates the width direction of the optical sheet 300 with W S The indicated width direction is parallel. In another aspect, at least one of the 14 light guide plates has a width direction perpendicular to the optical sheet 300 . For example, the light guide plate 250f...

Embodiment 3

[0077] The optical sheet 300 has a length Ls≈1436mm, a width Ws˜980mm, and a thickness Ds ranging from 0.1mm to 0.7mm. There are 21 light guide plate patterns on the optical sheet 300, each having a length varying between 150mm to 240mm and a width varying between 150mm to 320mm.

[0078] When the optical sheet 300 is manufactured at a processing speed of 152mm / sec, it takes about 9.4 seconds to manufacture one optical sheet 300 including 21 light guide plates. An average of less than 0.5 seconds to manufacture a light guide plate, the speed is much higher than the possible traditional injection molding method to produce the same light guide plate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com