Fuse mounting component

A technology for installing components and fuses, applied in the field of fuses, can solve the problems of fatigue fracture of internal components of fuses, limited degrees of freedom, fatigue fracture of fuse components, etc., to achieve the effects of not easy fatigue fracture, low cost, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the fuse mounting member of the present invention that does not cause fatigue in the internal components of the fuse even if the thermal expansion coefficients of the fuse and the fuse mounting member are different will be described with reference to the drawings.

[0021]

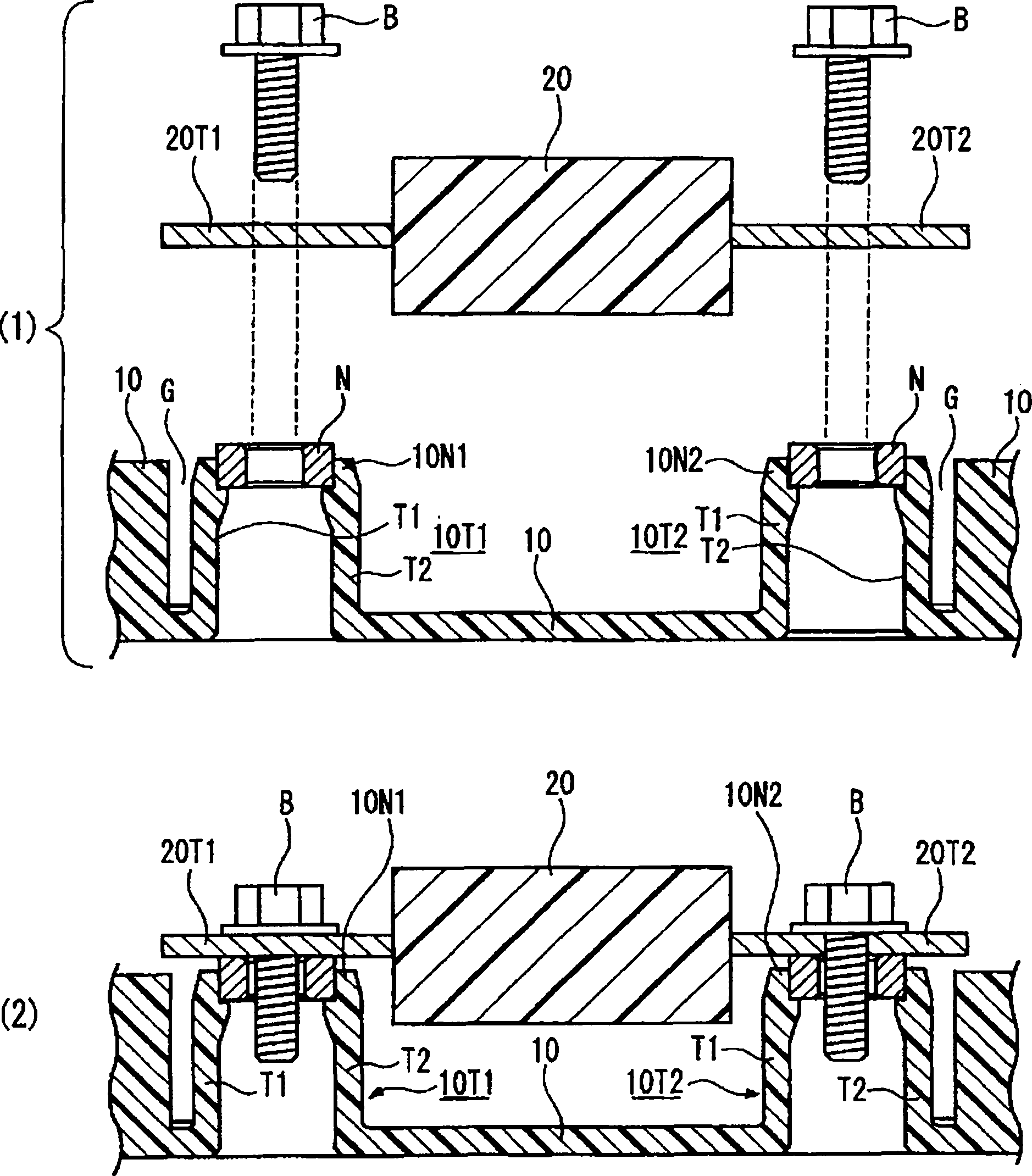

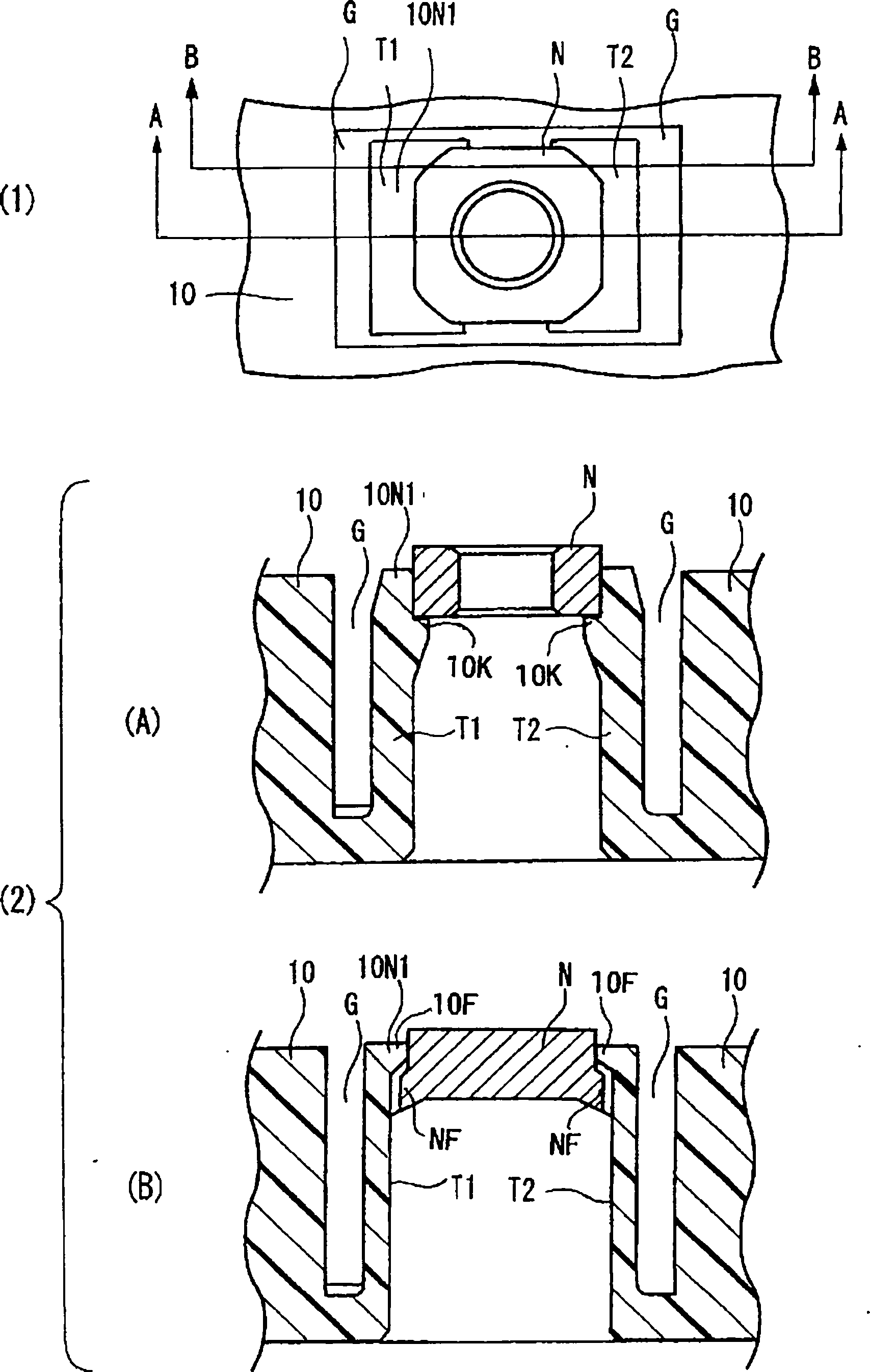

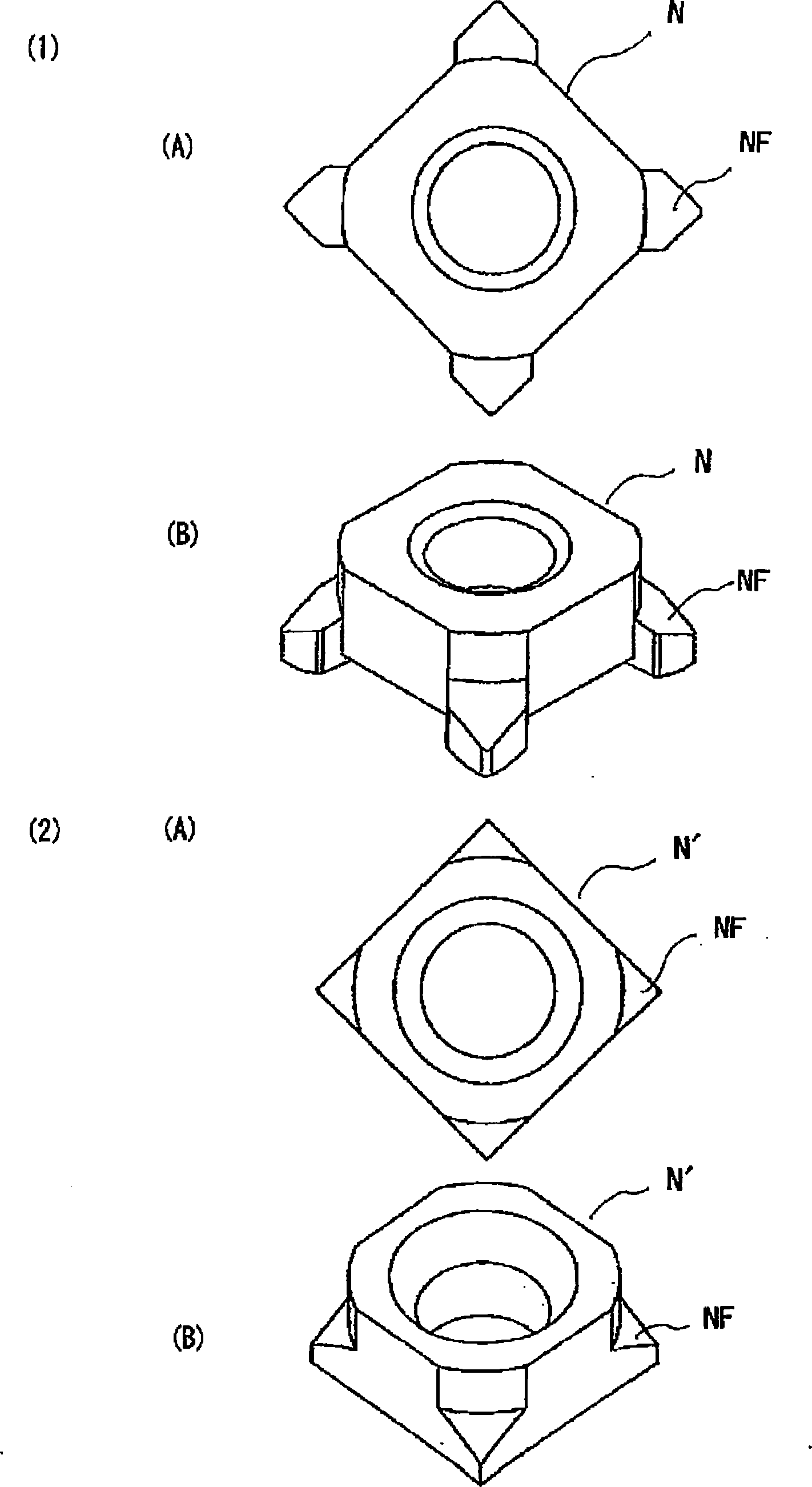

[0022] figure 1 and figure 2 It is a figure explaining the fuse mounting part which concerns on this invention. figure 1 It is a vertical cross-sectional view of the fuse installation part, wherein (1) shows the state before the fuse is installed; (2) shows the state after the fuse is installed. figure 2 yes means figure 1 The figure of the nut part of the fuse installation part of , wherein (1) is a top view; (2) is a longitudinal sectional view of the nut, wherein (A) is the A-A section of (1); (B) is the B-B of (1) section. exist figure 1 and figure 2 Among them, 10T1 and 10T2 are support portions of the present invention for fixing the nuts N, respectively. The suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com