Method for preparing pyrithione salt dispersed solution by injection coprecipitation method

A technology of pyridinethione salt and co-precipitation method is applied in the field of preparation of high-quality pyridinethione salt dispersion liquid, and can solve the problems of large particle size and wide particle size distribution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

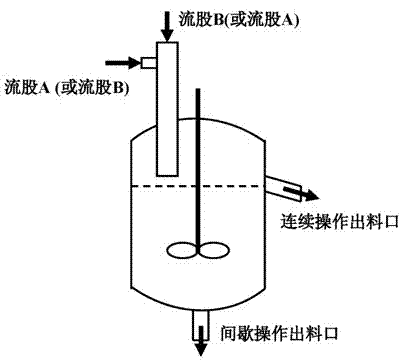

[0032] Adopt coaxial jet type jet reactor to prepare pyrithione copper dispersion liquid, the outer tube of jet reactor is the round tube of inner diameter 10mm, the inner sleeve pipe of coaxial jet is arranged at the inlet center of jet reactor, the inner sleeve pipe The diameter is 3mm, and the length from the outlet of the inner casing to the outlet of the jet reactor is 50mm. The outlet of the jet reactor is above the liquid level of the stirred reactor. The stirred reactor is a standard type stirred tank, and its effective volume is 200L, the stirred tank adopts continuous operation.

[0033] The laser-induced fluorescence technique was used to evaluate the physical mixing time of two streams of water in a coaxial jet-type jet reactor. Laser-induced fluorescence technology is an advanced quantitative evaluation method for evaluating fluid mixing effects. Its main principle is to use some fluorescent substances (such as rhodamine B, rhodamine 6G, acetone, etc.) Visible li...

Embodiment 2

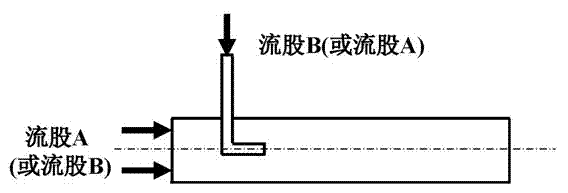

[0037] The zinc pyrithione dispersion was prepared by using a small-hole jet jet reactor. The central tube of the jet reactor was a circular tube with an inner diameter of 20 mm, and six small diameter tubes with a diameter of 3 mm were evenly distributed on the tube wall at a distance of 50 mm from the entrance of the circular tube. The hole, the distance from the small hole to the outlet of the jet reactor is 300mm. The outlet of the jet reactor is located above the liquid level of the stirred reactor. The stirred reactor is a standard type stirred tank with an effective volume of 50L. The stirred tank Use intermittent operation. The same laser-induced fluorescence technique as in Example 1 was used to evaluate the physical mixing time of the small-hole jet jet reactor for two streams of water. In the jet reactor, the time for the two fluids to reach 95% physical mixing was 7.7 milliseconds.

[0038] Stream A is an aqueous solution of zinc sulfate, which enters the jet react...

Embodiment 3

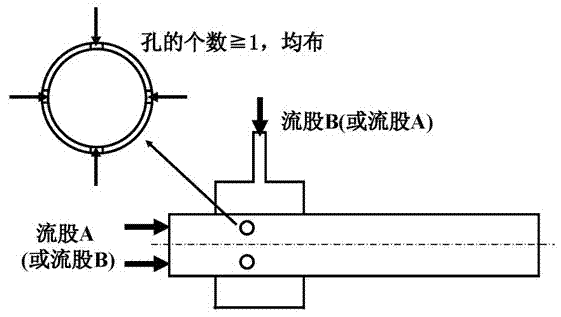

[0041] Adopt impingement flow jet reactor to prepare magnesium pyrithione dispersion, the impingement mixing zone is a circular tube with an internal diameter of 30mm, and the length is 20mm, and two liquid nozzles are symmetrically placed on the tube wall of the impingement mixing zone, stream A and stream Strand B enters the liquid nozzle through the feed pipe connected to the two liquid nozzles, and after being sprayed out from the nozzle, it mixes and reacts in the impact mixing area. A circular tube with a length of 50mm and an inner diameter of 15mm is connected to the lower part of the impact mixing area. , the mixed reaction solution enters the connected reaction tube through the impact mixing zone for further reaction, and then it is discharged into the stirred tank. The outlet of the jet reactor is located above the liquid level of the stirred reactor. The stirred reactor is a standard type stirred tank. The effective volume is 20L, and the stirred tank adopts intermi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap