Optical fiber electric heat tape

A technology of electric heating belt and optical fiber, which is applied in the direction of measuring heat, heating element shape, measuring device, etc., can solve the problem of difficulty in accurately determining the fault point of electric heating belt, and achieve the effect of facilitating maintenance and ensuring safe transportation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

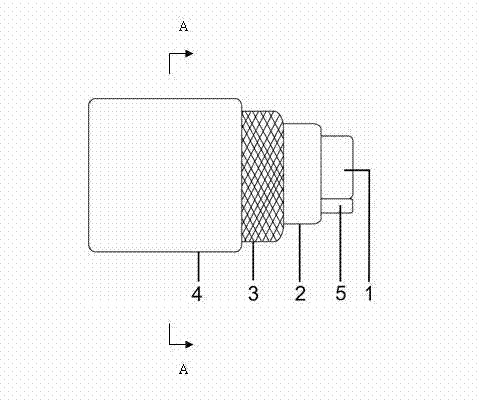

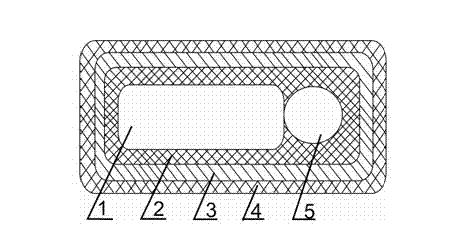

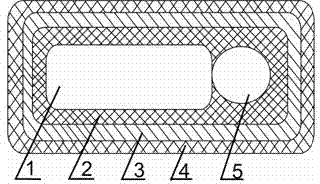

[0007] Specific implementation mode one : combined below figure 1 and figure 2 This embodiment will be specifically described. This embodiment includes an electric heating belt body 1, which also includes an optical fiber 5, an inner sheath 2, a shielding layer 3 and an outer sheath 4. Rely, the inner sheath 2, the shielding layer 3 and the outer sheath 4 are wrapped sequentially from the inside to the outside on the heating belt body 1 and the outer wall of the optical fiber 5.

specific Embodiment approach 2

[0008] Specific implementation mode two : combined below figure 1 and figure 2 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that the heating belt body 1 is a series heating belt or a parallel heating belt.

specific Embodiment approach 3

[0009] Specific implementation mode three : combined below figure 1 and figure 2 This embodiment will be specifically described. The difference between this embodiment and the first embodiment is that the heating belt body 1 is a constant temperature heating belt or a self-limiting temperature heating belt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com