Steam vortex type ammonium nitrate dissolver

An ammonium nitrate, eddy current technology, applied in the directions of dissolution, dissolution, ammonium nitrate, etc., can solve the problems of difficult steam heat release, slow dissolution speed, low energy utilization rate, etc., to improve the dissolution efficiency and improve the contact speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

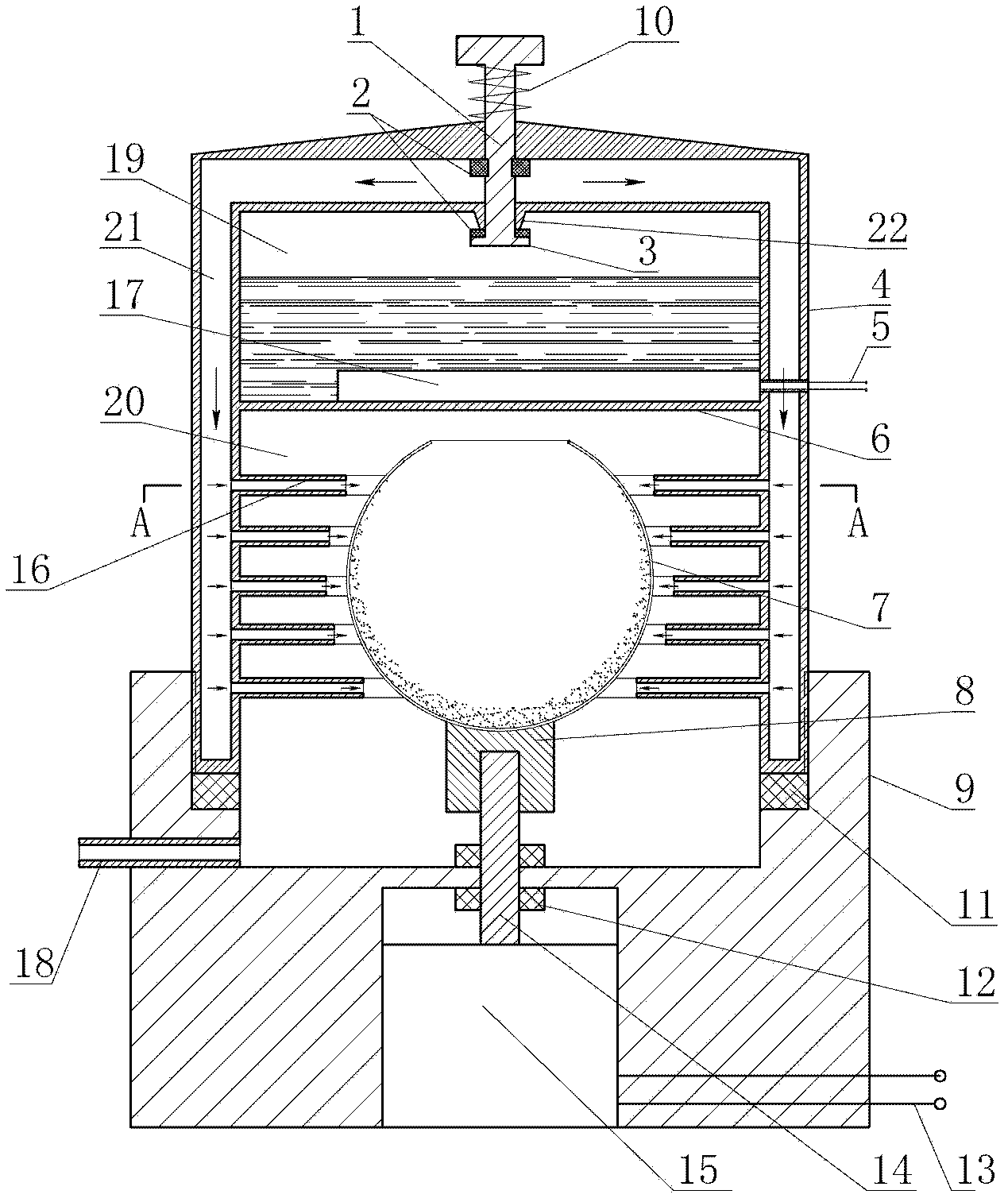

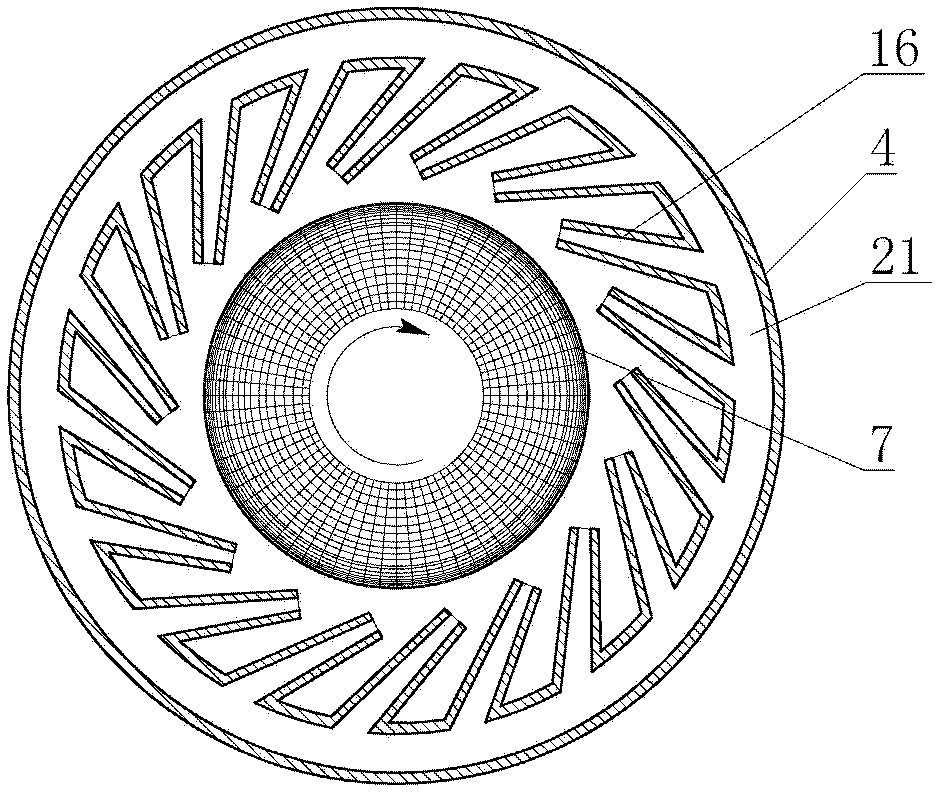

[0017] The steam vortex type ammonium nitrate dissolver consists of a button 1, a sealing ring 2, a sealing bowl 3, a steam cylinder 4, a resistance power cord 5, a thermal insulation partition 6, a sieve ball shell 7, a sieve ball handle 8, a base 9, a spring 10, Sealing gasket 11, sealing ring 12, motor power cord 13, motor shaft 14, motor 15, nozzle 16, heating resistor 17, solution outlet 18, water storage space 19, dissolution space 20, interlayer space 21 and air release nozzle 22 constitute.

[0018] The steam cylinder 4 is a double-layer casing with a cylindrical shape, a closed upper end and an open lower end. The steam drum 4 has an interlayer space 21 , and the cylindrical space in the steam drum 4 is divided into an upper water storage space 19 and a lower dissolution space 20 by a horizontally arranged heat-insulating partition 6 integrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com