Metering rotary split charging valve

A rotary valve and sub-packaging technology, which is applied in the direction of packaging, transportation and packaging, and the type of packaged items, can solve the problems of difficult guarantee of loading efficiency and sub-packaging accuracy, so as to ensure loading efficiency, fast feeding and accurate feeding , The effect of ensuring the accuracy of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

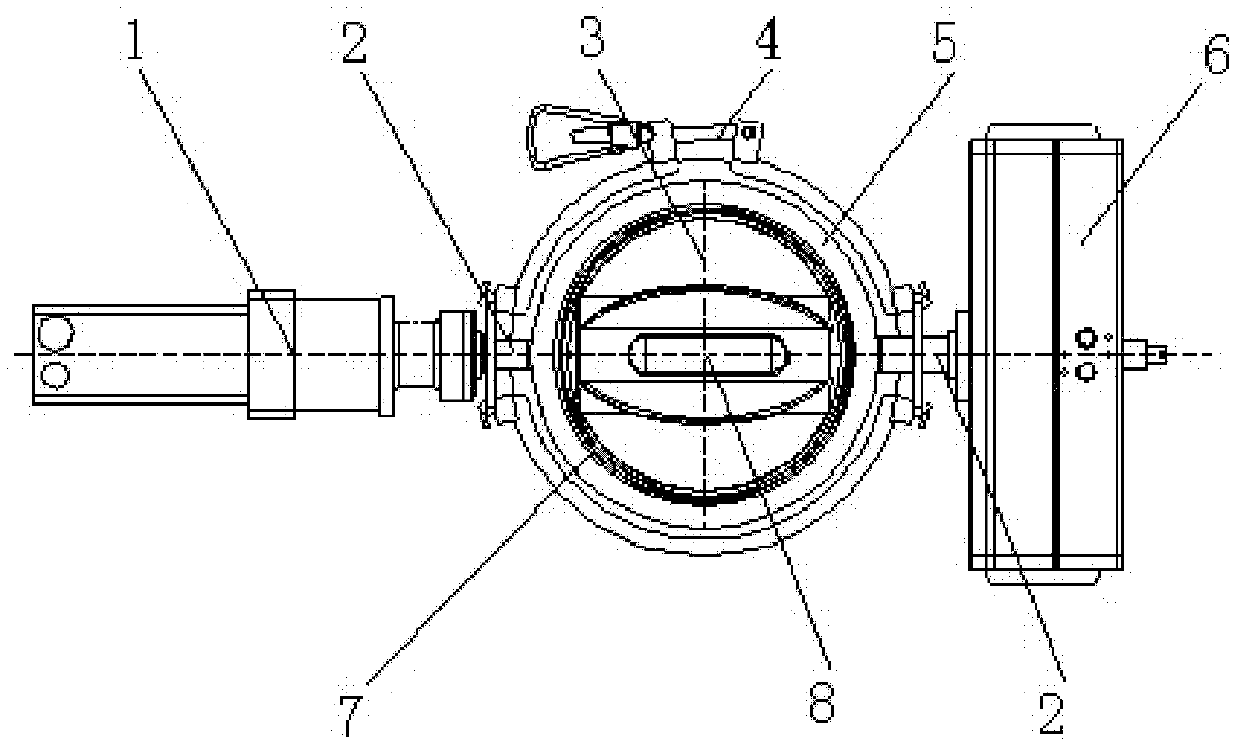

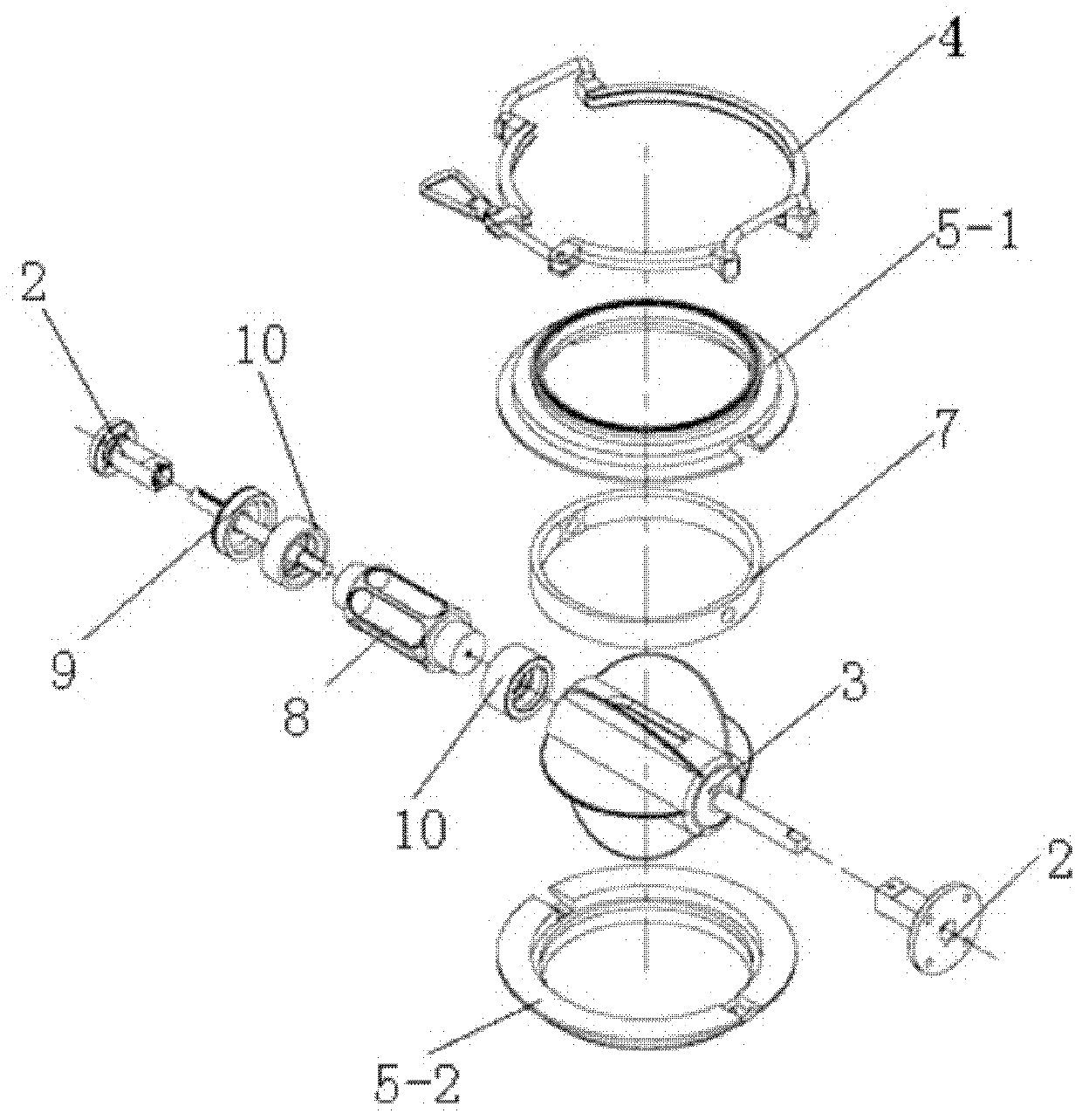

[0012] The metering and dispensing rotary valve of the present invention, its preferred embodiment is as follows figure 1 , figure 2 Shown:

[0013] It includes a housing, a large rotor is provided in the housing, a small rotor is provided in the large rotor, the rotation center of the large rotor is coaxial with the small rotor, the drive shaft of the large rotor is connected with the pneumatic actuator, the The drive shaft of the small rotor is connected with the air motor.

[0014] The housing includes an upper flange and a lower flange, and the upper flange and the lower flange are connected by a clamp. Housings of other structural forms in the prior art may also be used.

[0015] A valve plate sealing ring is provided at the seam of the upper flange and the lower flange.

[0016] The drive shaft of the large rotor and the pneumatic a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com