A station tool for handling cylinder head test pieces

A technology of station equipment and cylinder head, applied in the directions of transportation, packaging, roller table, etc., can solve the problems of large amount of labor, long test preparation time, inability to meet the takt time requirements of production line, etc., to reduce labor amount, operate quickly, reduce Effects of security risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Next, with reference to the accompanying drawings, the specific embodiments of the present invention, such as the structures of the various components involved, their mutual positions and connection relations are further described, so as to help those skilled in the art to have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention. understanding.

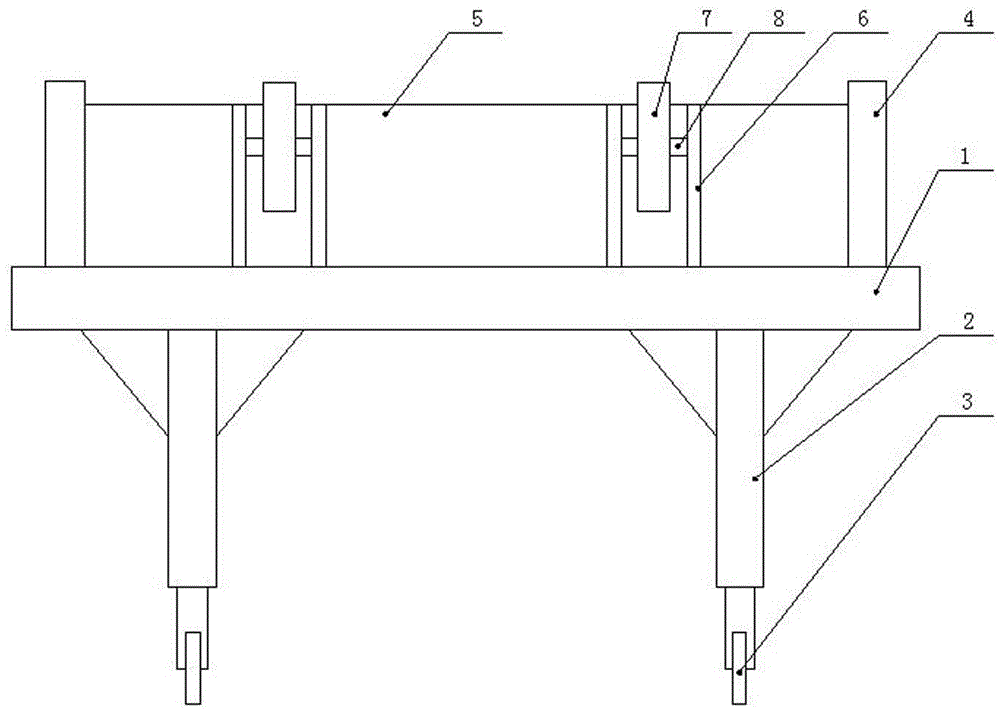

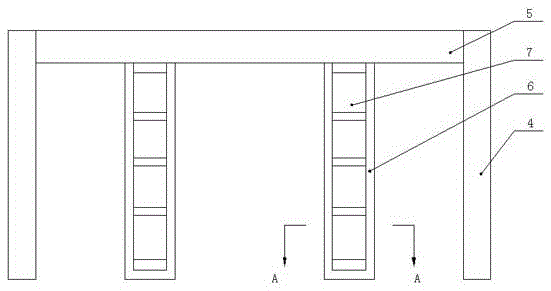

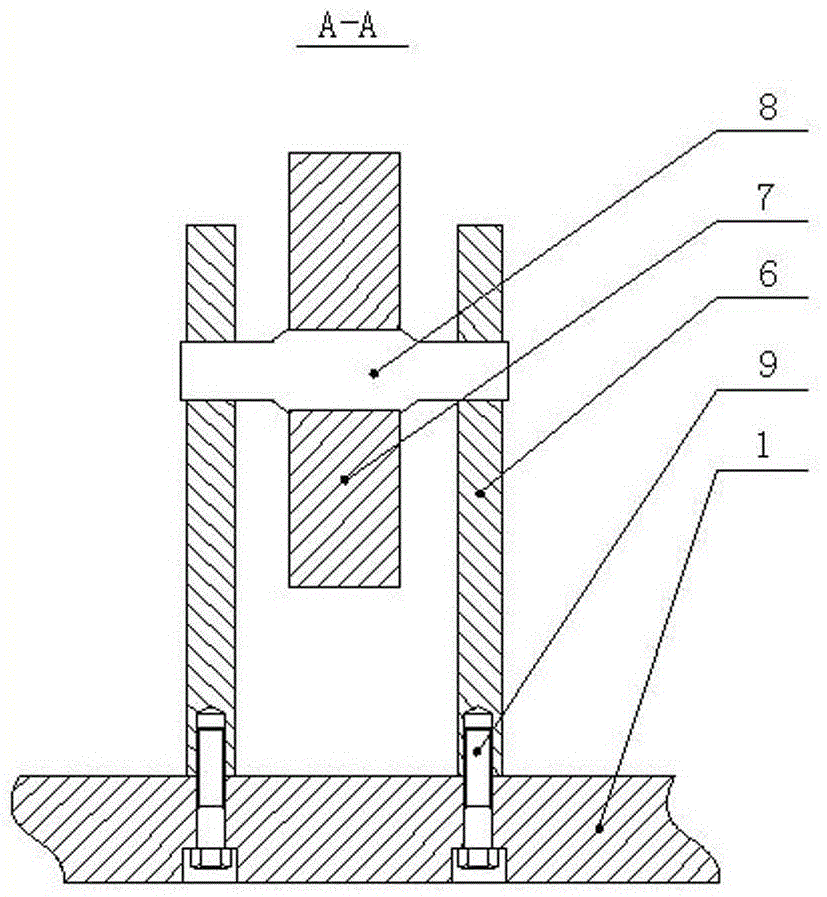

[0010] Such as figure 1 , 2 Shown in , 3: a kind of station equipment for cylinder head test piece handling of the present invention comprises base plate 1, and four brackets 2 are fixedly assembled on the lower surface of base plate 1. The runner 3 that can rotate is installed at the bottom of the four supports 2 . The upper surface of the base plate 1 is fixedly assembled with two straight rails 4 and a cross rail 5, and the upper surface of the bottom plate 1 is also fixedly installed with two sets of roller bearings 6 that are symmetrical and para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com