Patents

Literature

35results about How to "Meet the beat requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

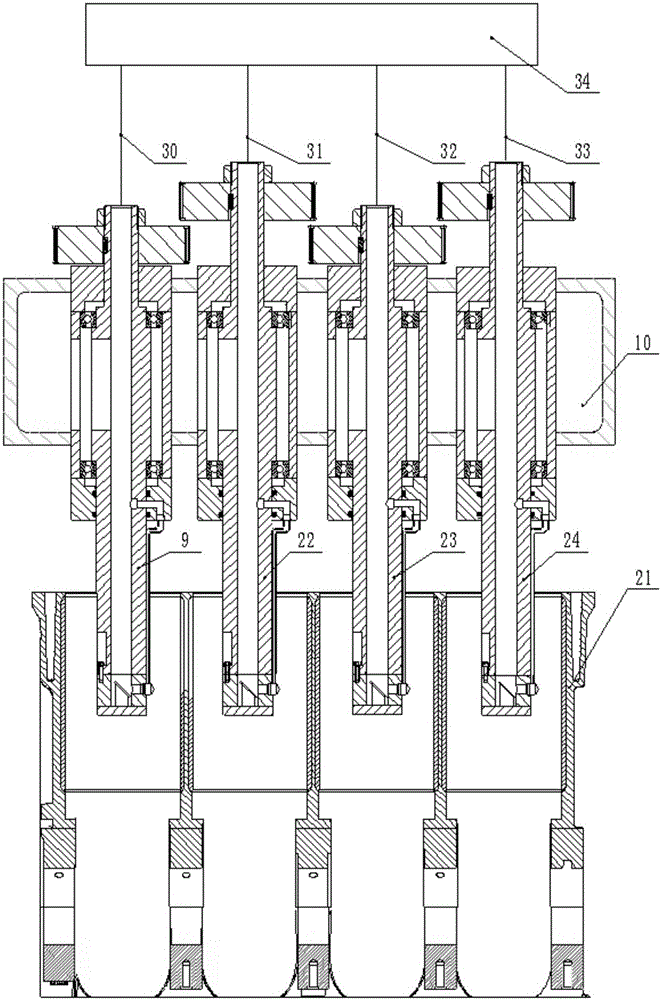

Automatic verification system and method for electric energy meter

ActiveCN106125036AReduce feeding pressureReasonable utilizationElectrical measurementsProgrammable logic controllerEngineering

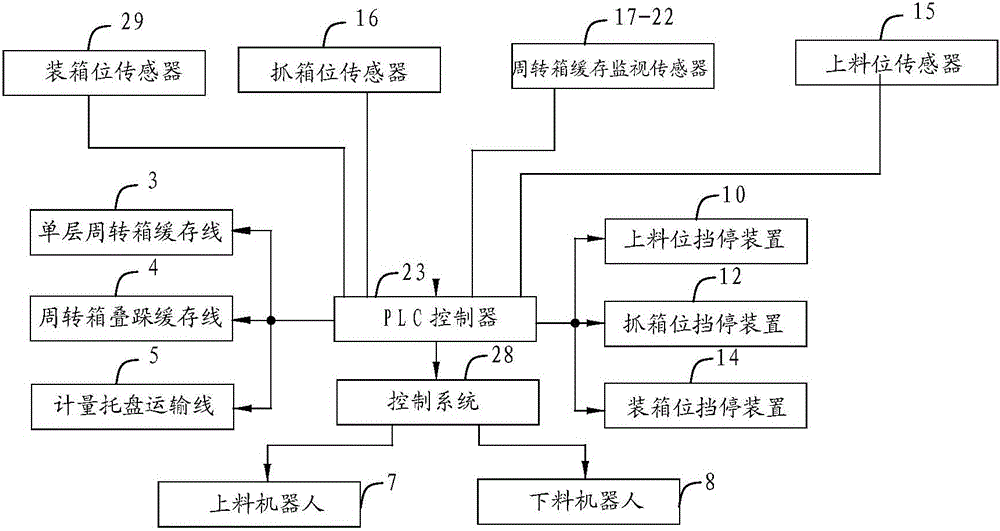

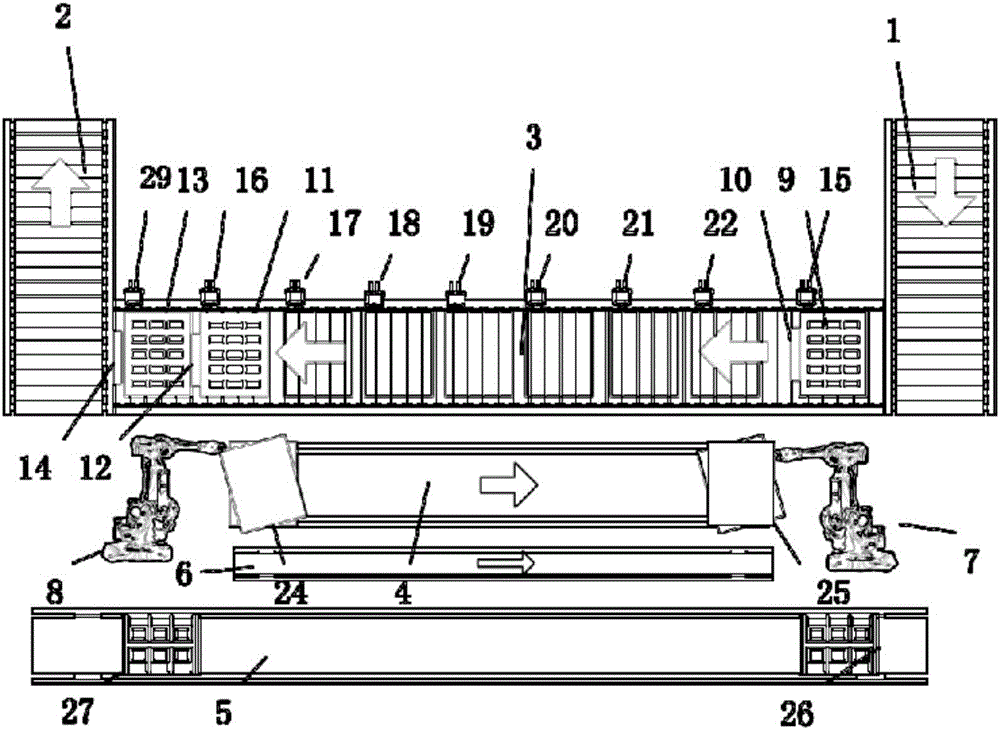

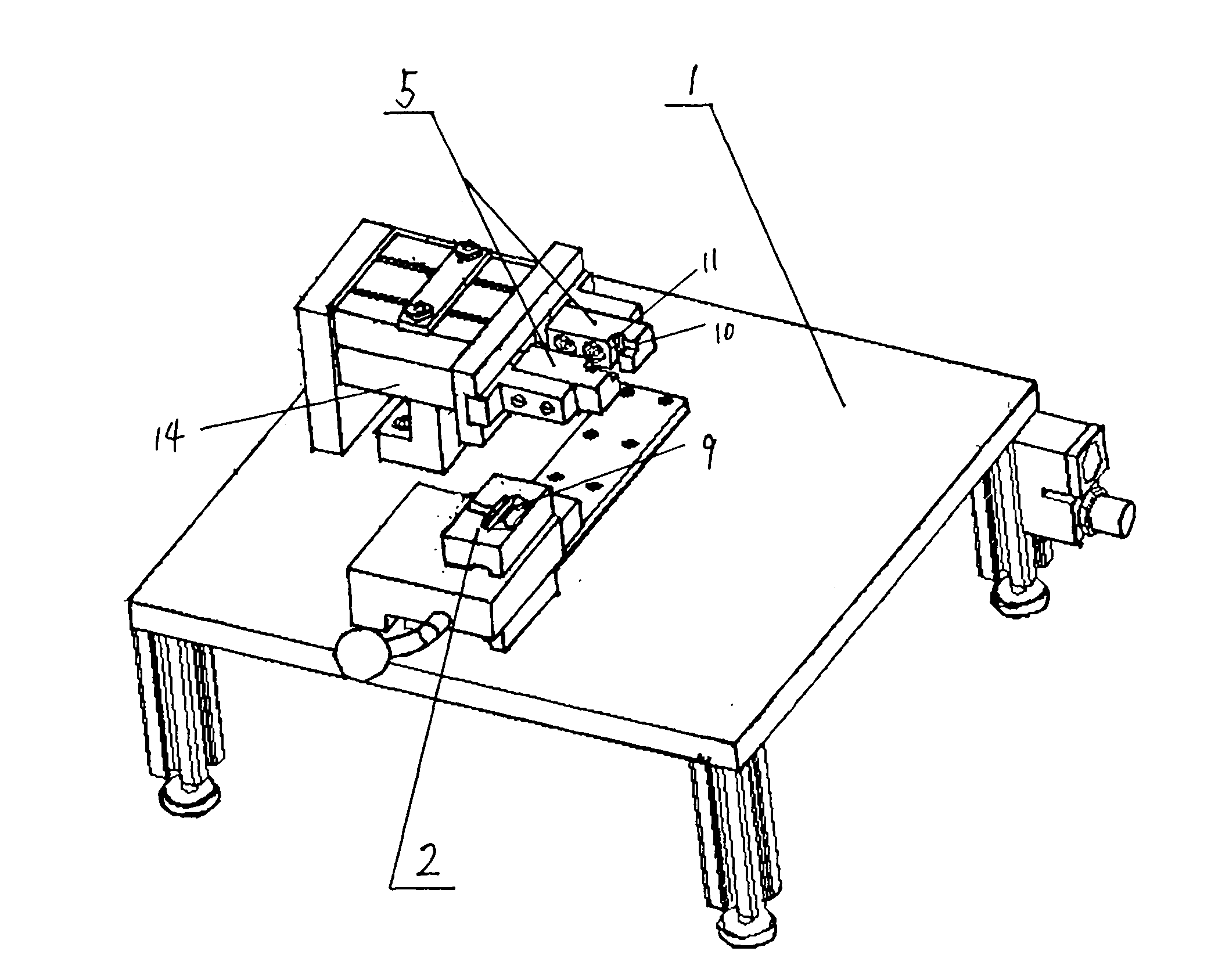

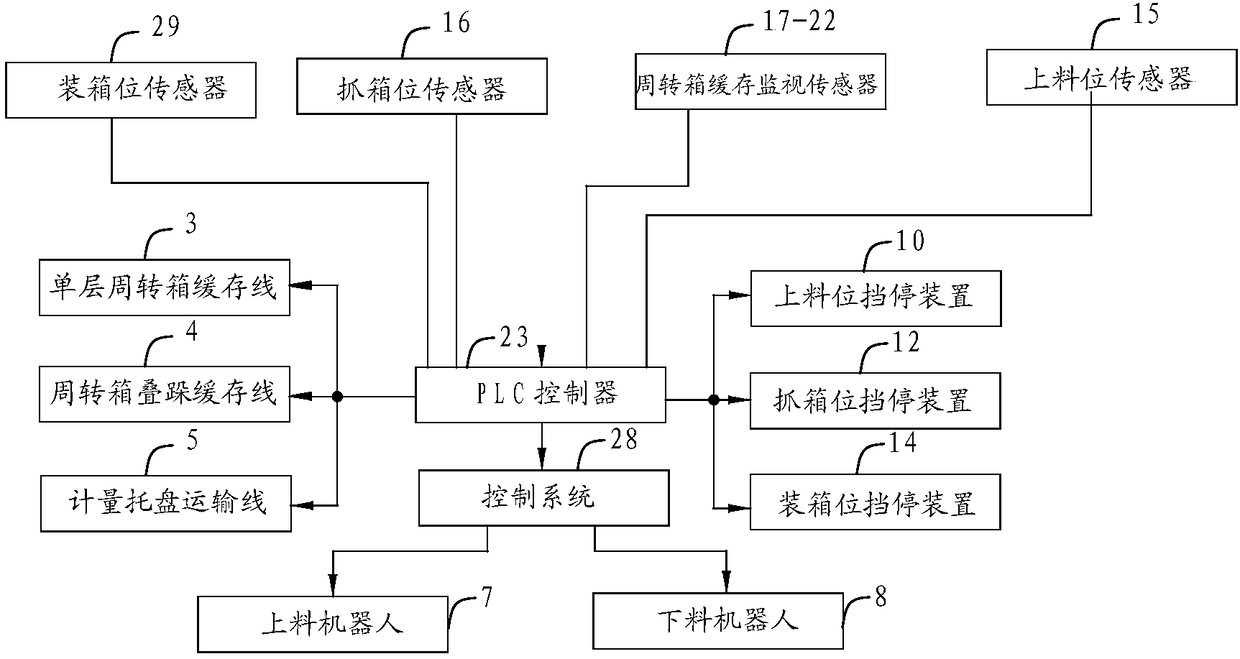

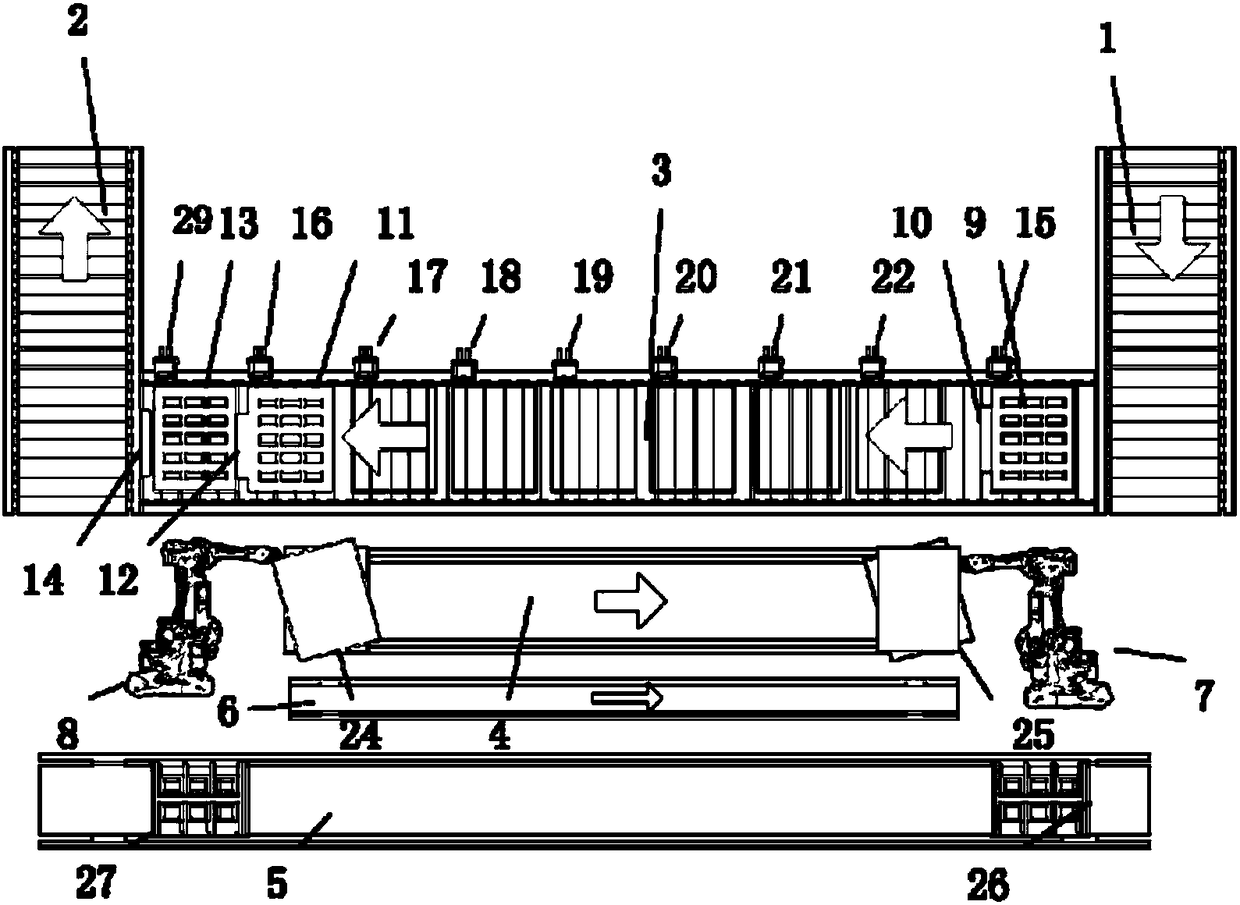

The invention provides an automatic verification system and method for an electric energy meter. The system comprises a PLC (Programmable Logic Controller), a delivery roller transport line controlled by the PLC and used for delivering turnover boxes out of a storage, a return roller transport line for returning the turnover boxes to the storage, a single-layer turnover box cache line for transporting the turnover boxes, a turnover box stacking cache line for caching the turnover boxes, an electric energy meter recheck belt line for transporting unqualified electric energy meters; a metering tray transport line for transporting a metering tray, a feeding robot and a discharging robot for moving electric energy meters or turnover boxes, and a turnover box monitoring sensor connected with the PLC and arranged on the single-layer turnover box cache line. By adopting the caching mode of combining a single-layer turnover box cache area with a multi-layer turnover box stacking area and intelligently transporting the turnover boxes via roller lines, the task executed by each robot at the same moment is balanced, the action path of a single robot is simplified, and the operating efficiency of the feeding and discharging robots is greatly improved.

Owner:STATE GRID CORP OF CHINA +1

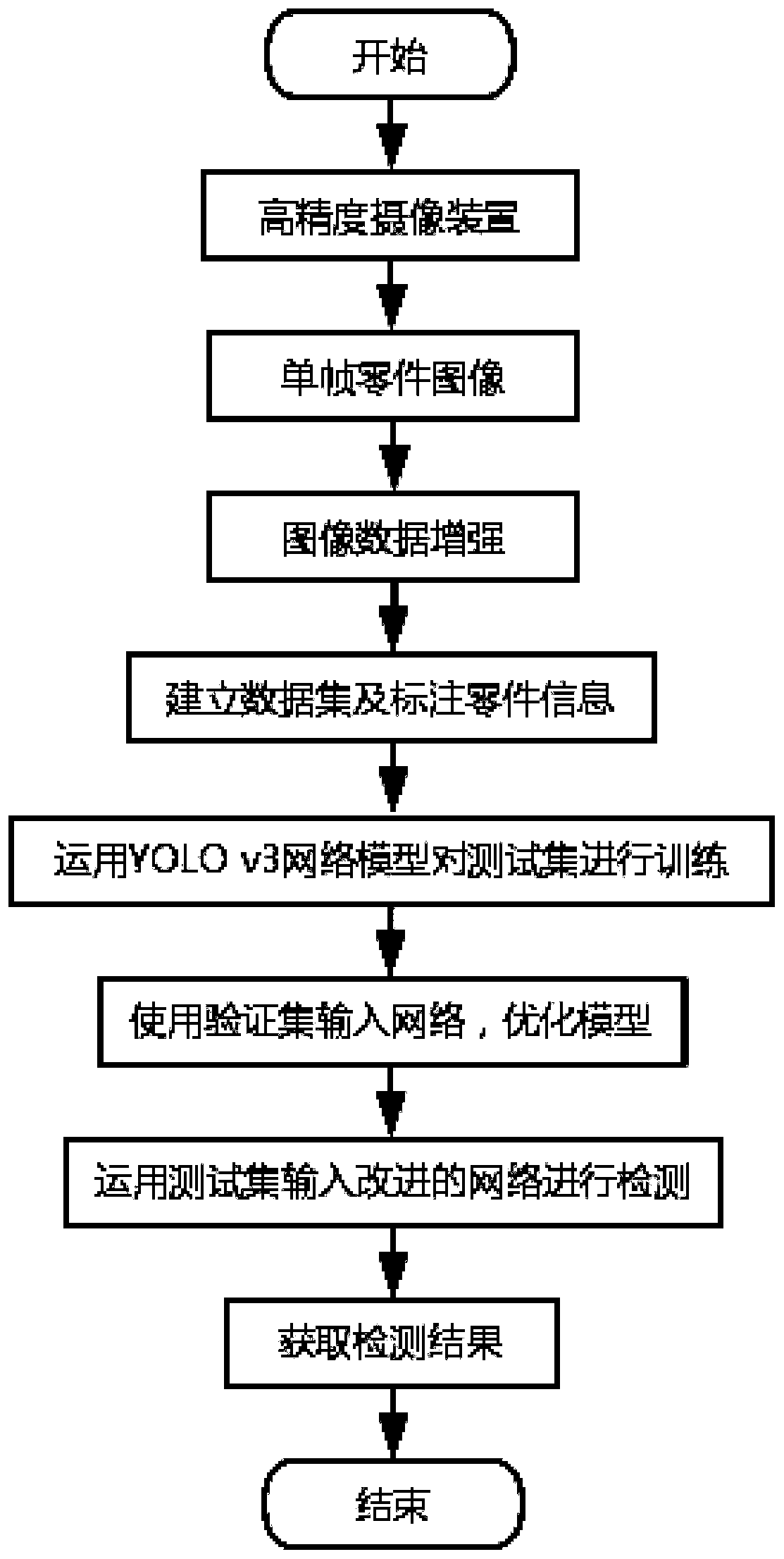

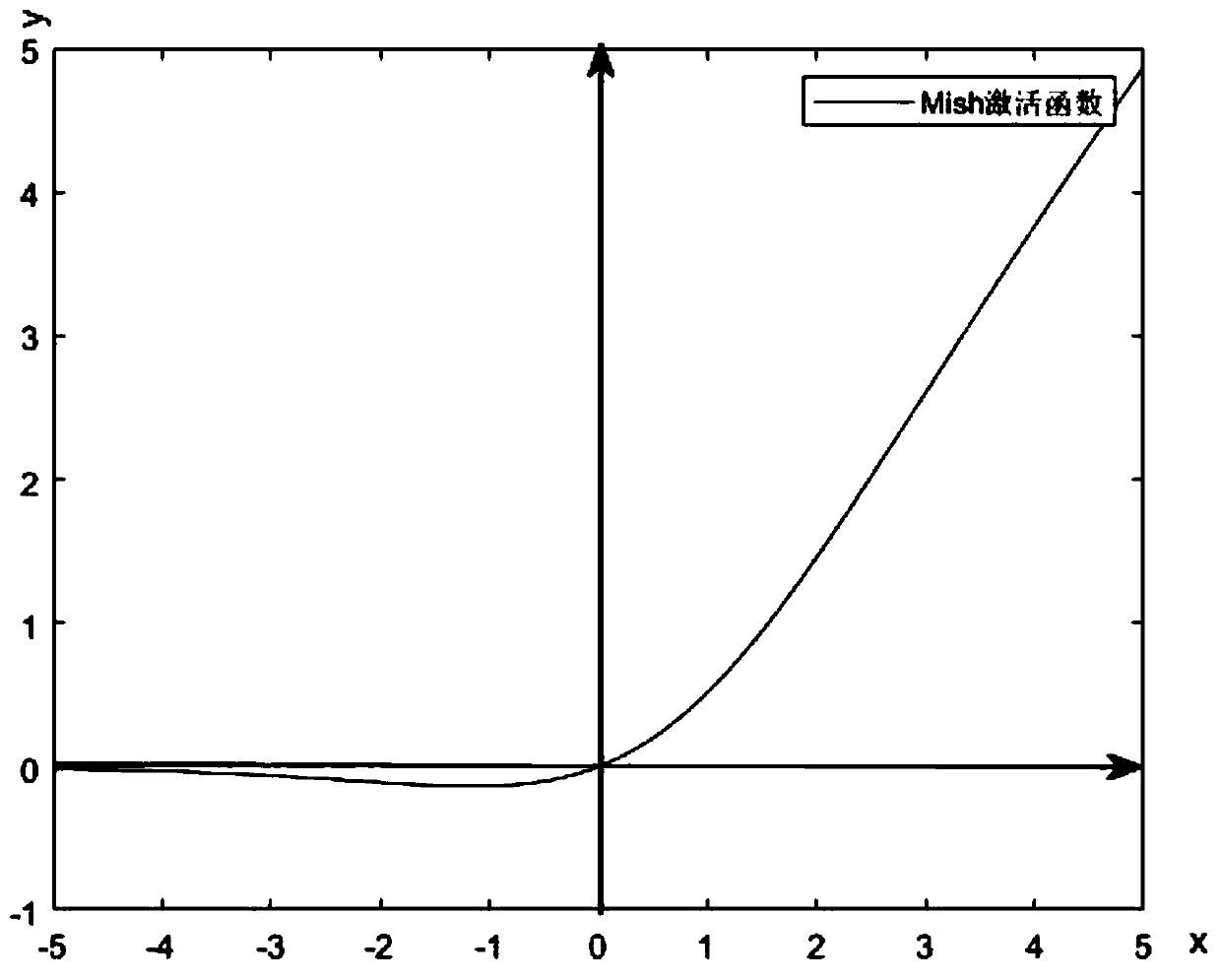

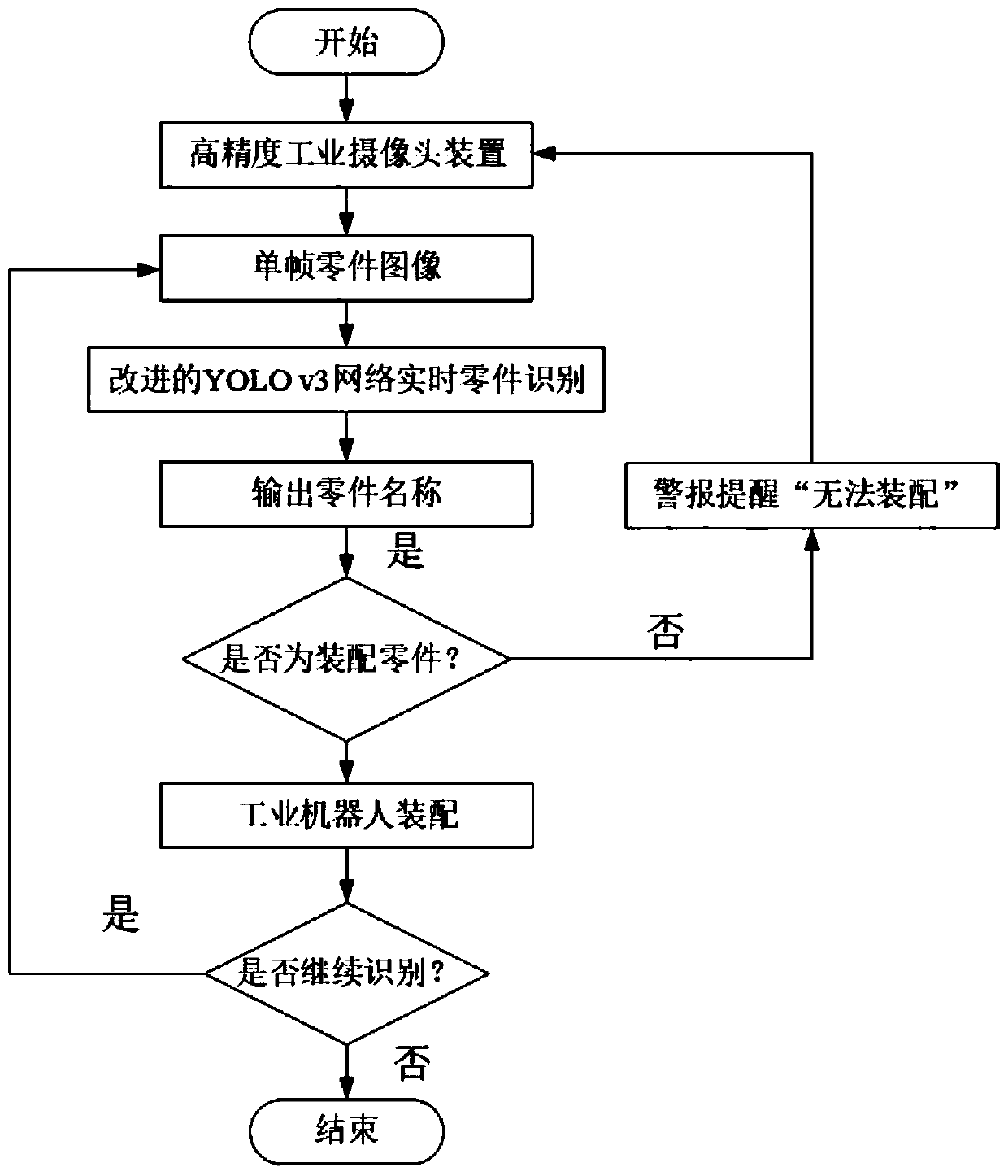

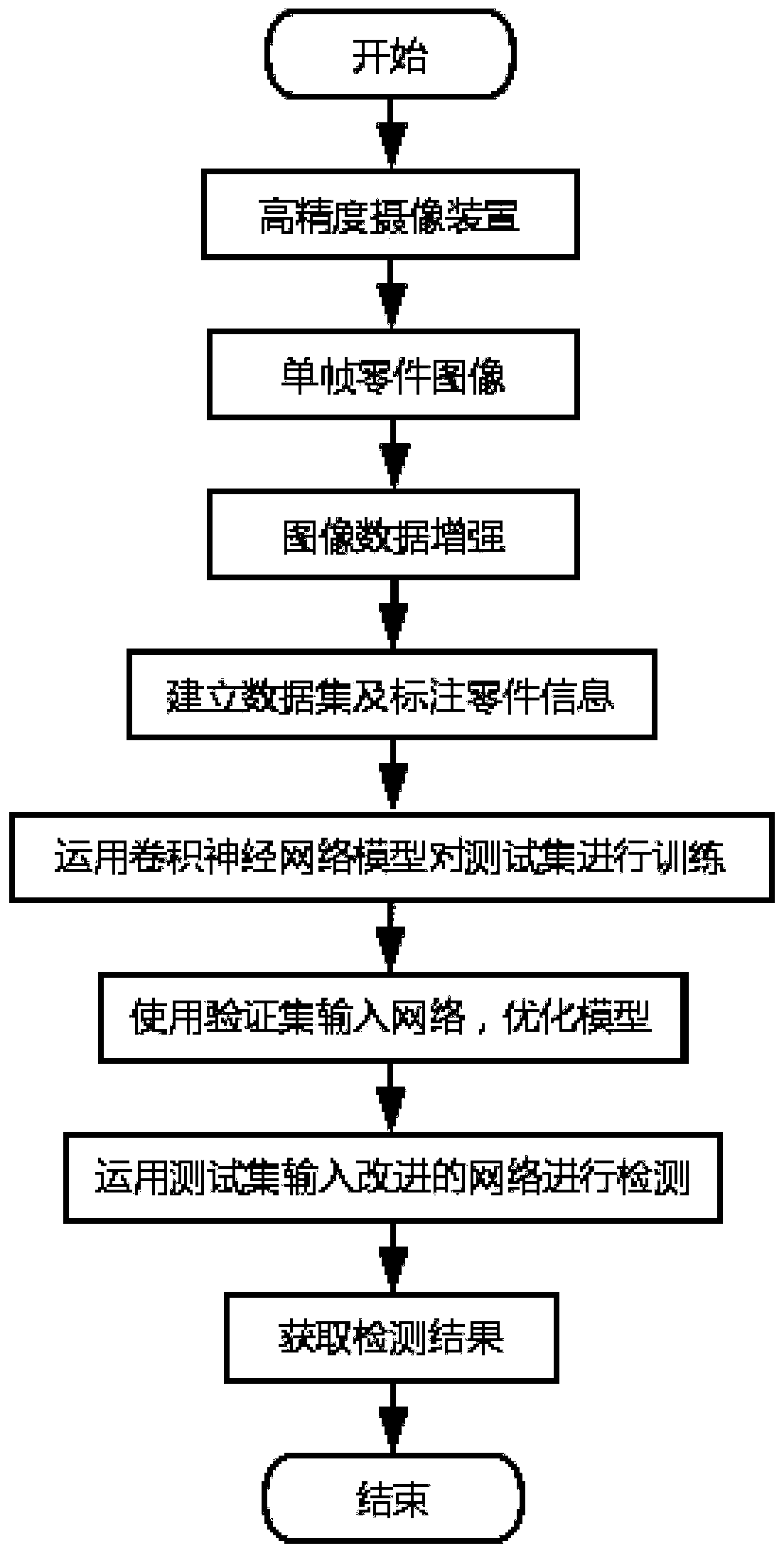

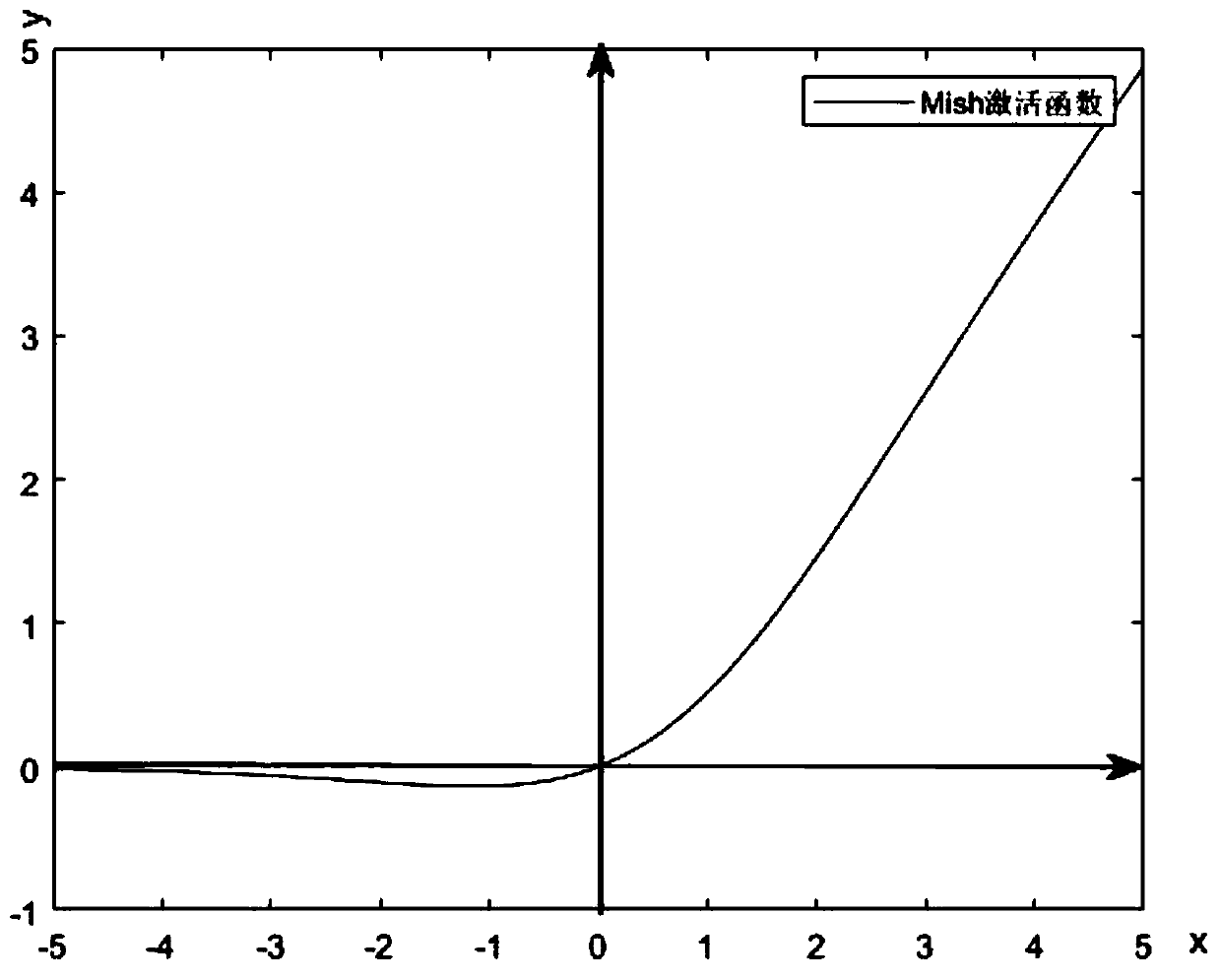

Industrial part detection method based on YOLO v3 neural network

InactiveCN111429418AHigh precisionHigh speedImage analysisCharacter and pattern recognitionData setEngineering

The invention relates to an industrial part detection method based on a YOLO v3 neural network. The method comprises the following steps: step 1, collecting an industrial part video sample; step 2, acquiring a single-frame image of the video sample of the industrial part acquired in the step 1, forming a basic data set, performing data enhancement on the images of the basic data set to form an industrial part data set, labeling the position and category information of the industrial parts in the industrial part data set, and dividing the labeled industrial part data set into a sample trainingset, a verification set and a test set; step 3, generating a trained convolutional neural network detection model of the industrial part; and step 4, inputting the test set into an improved industrialpart convolutional neural network detection model to obtain a detection result. According to the invention, operations such as detection and classification of industrial parts can be quickly and efficiently identified in a dynamic environment.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

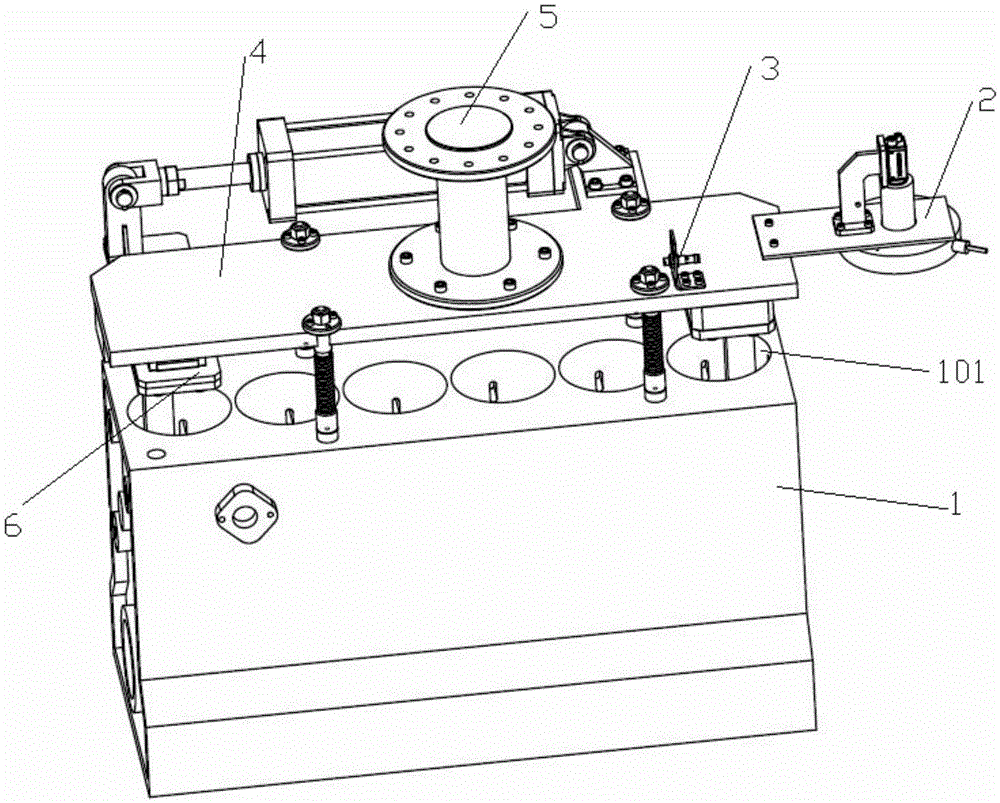

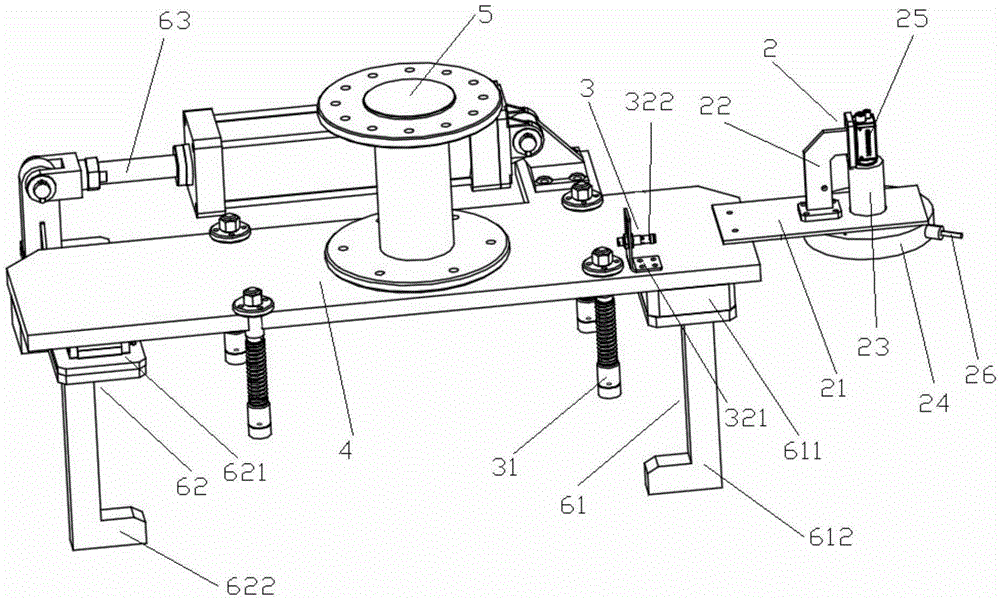

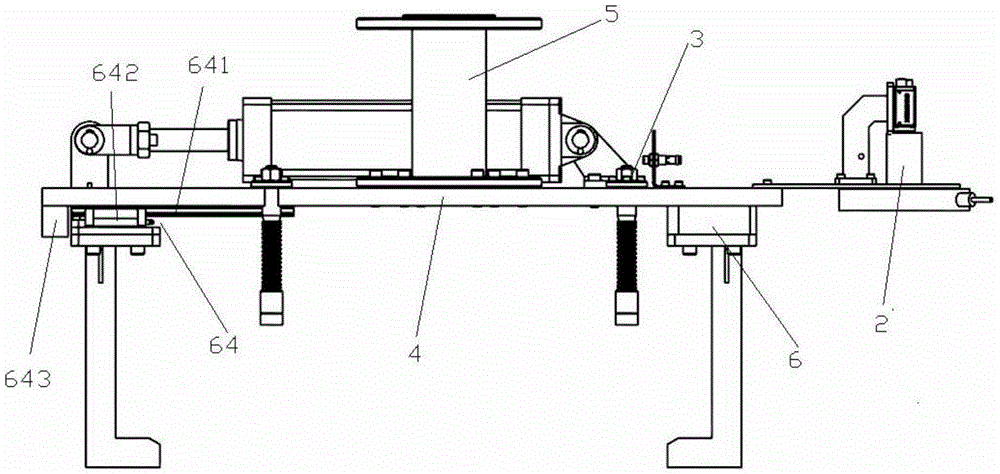

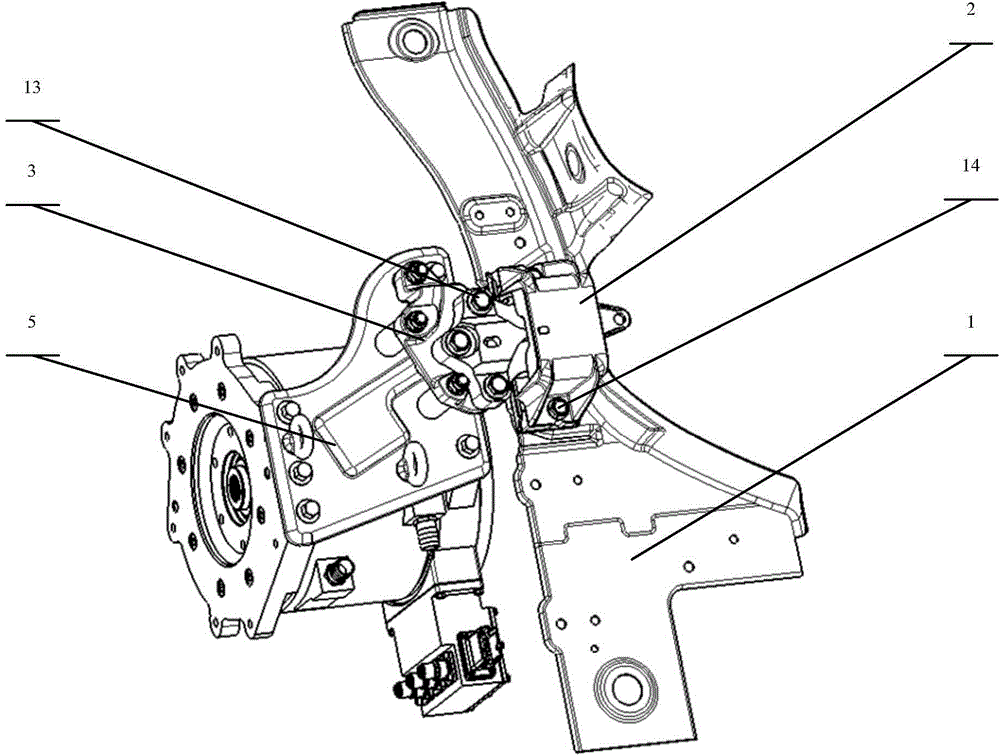

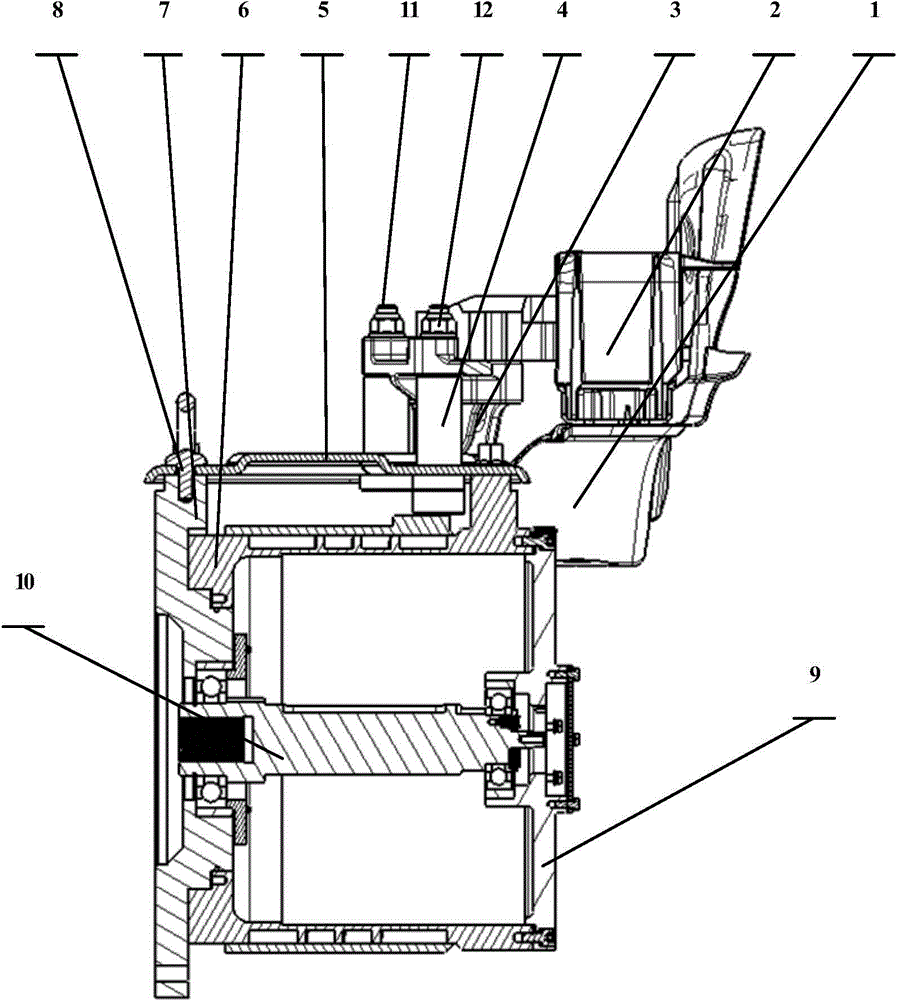

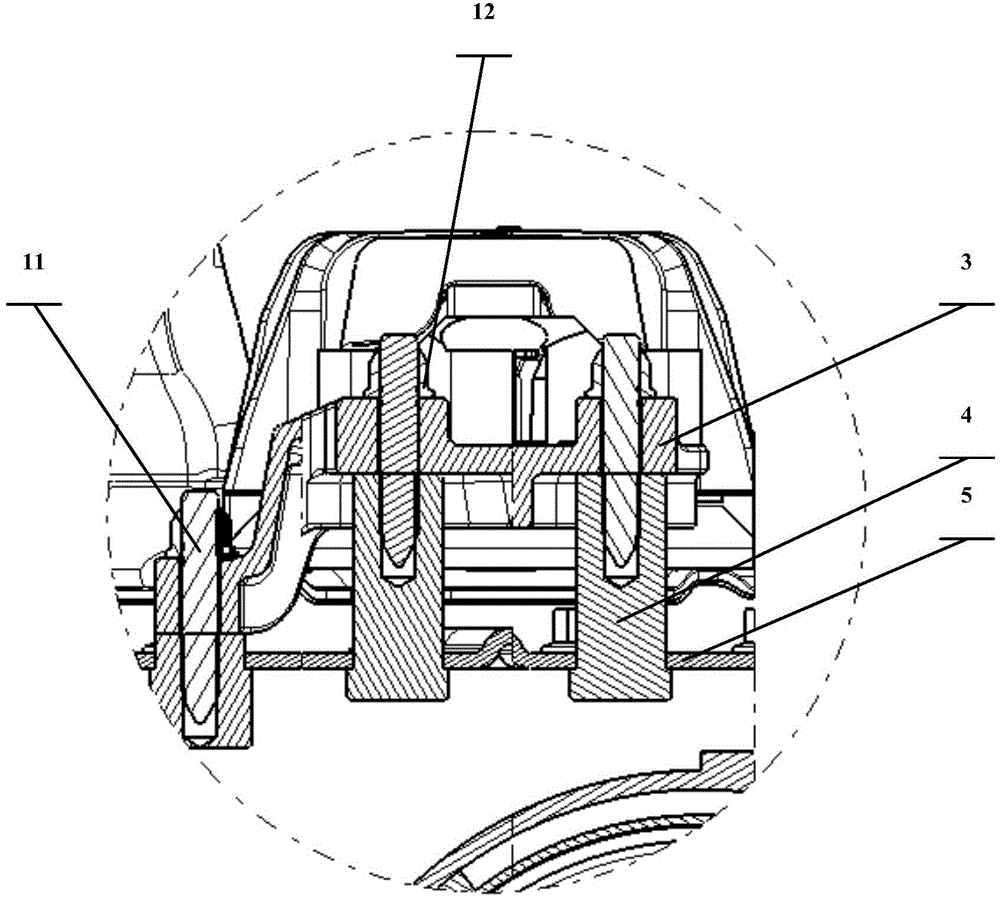

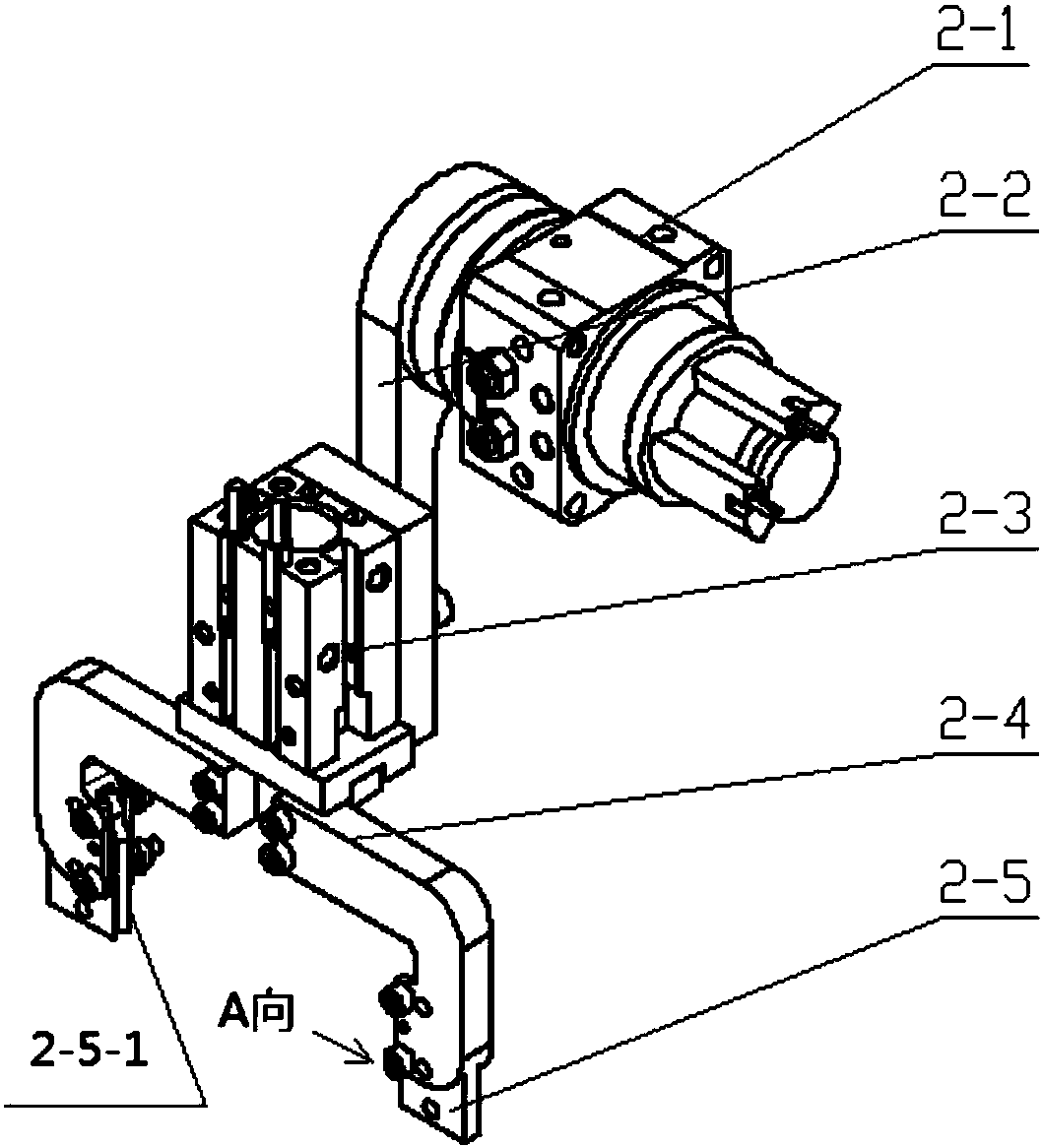

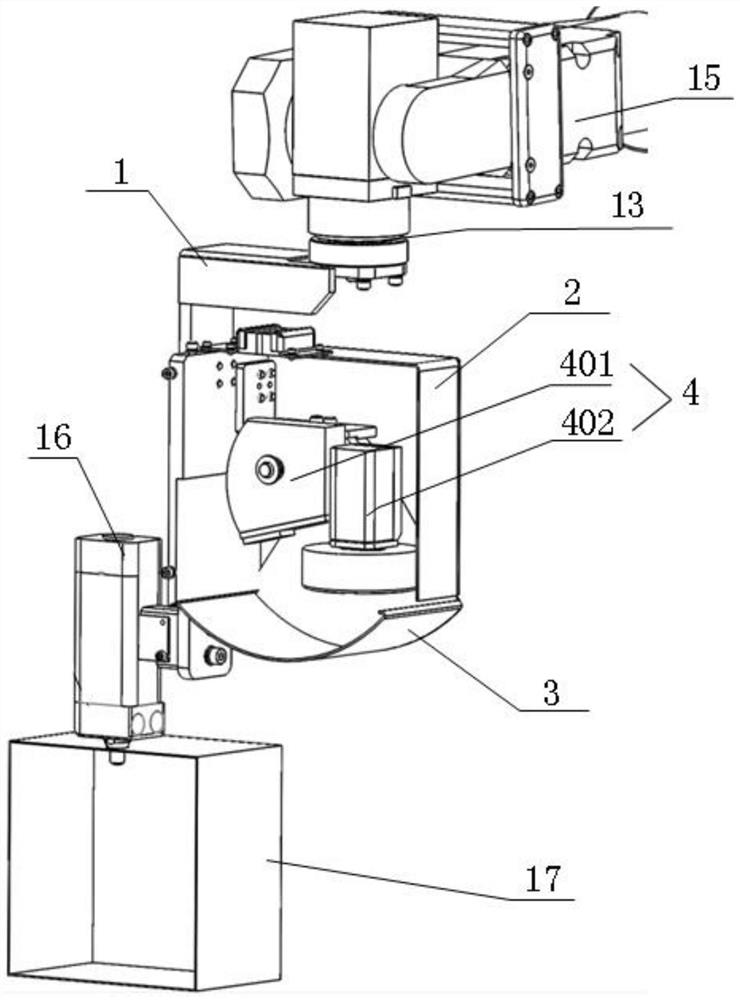

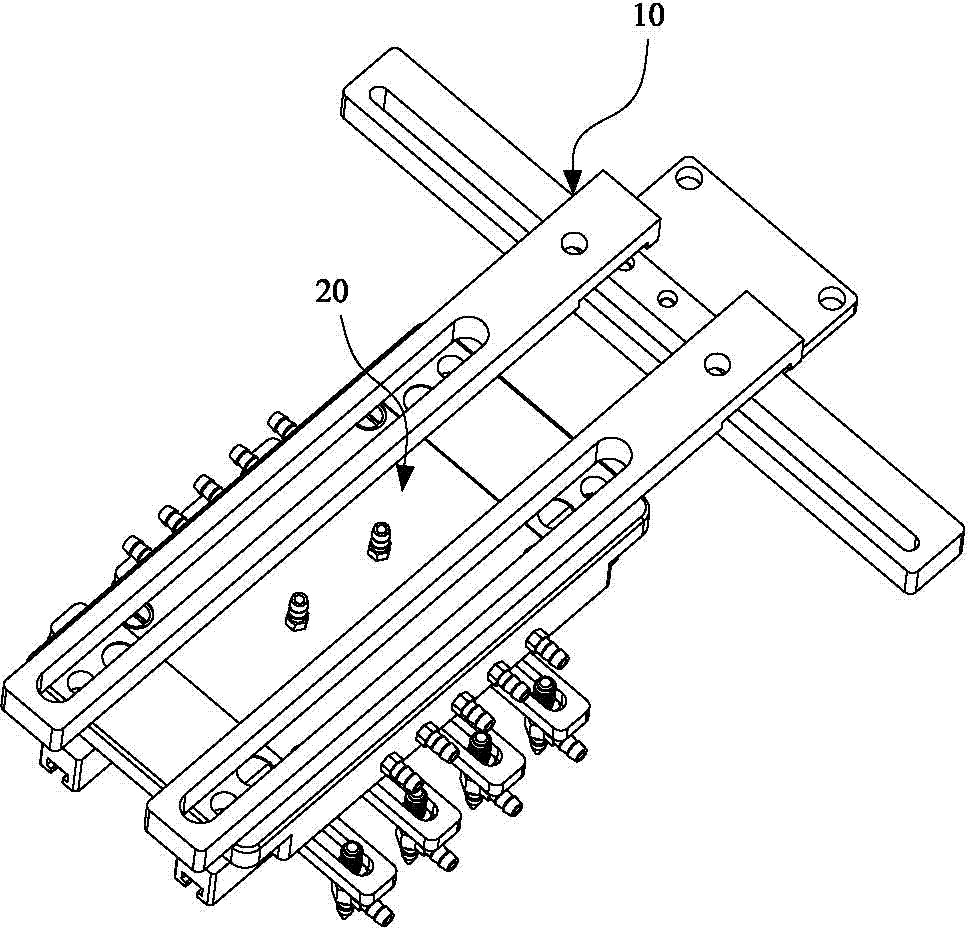

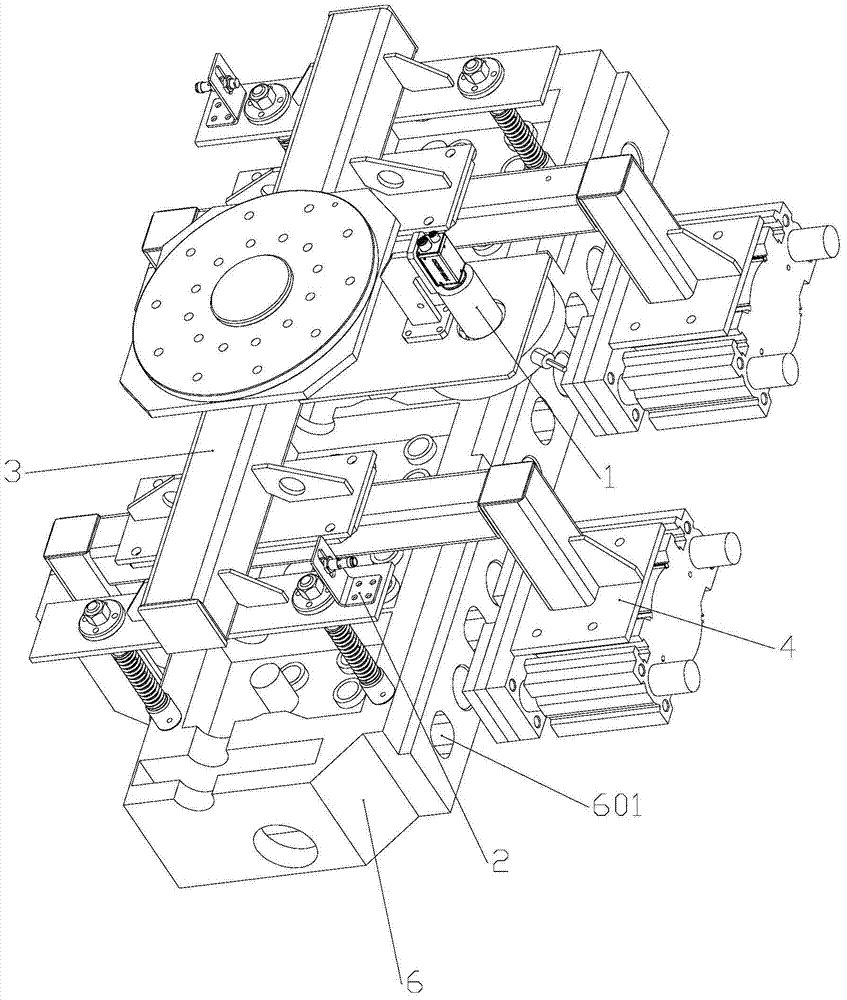

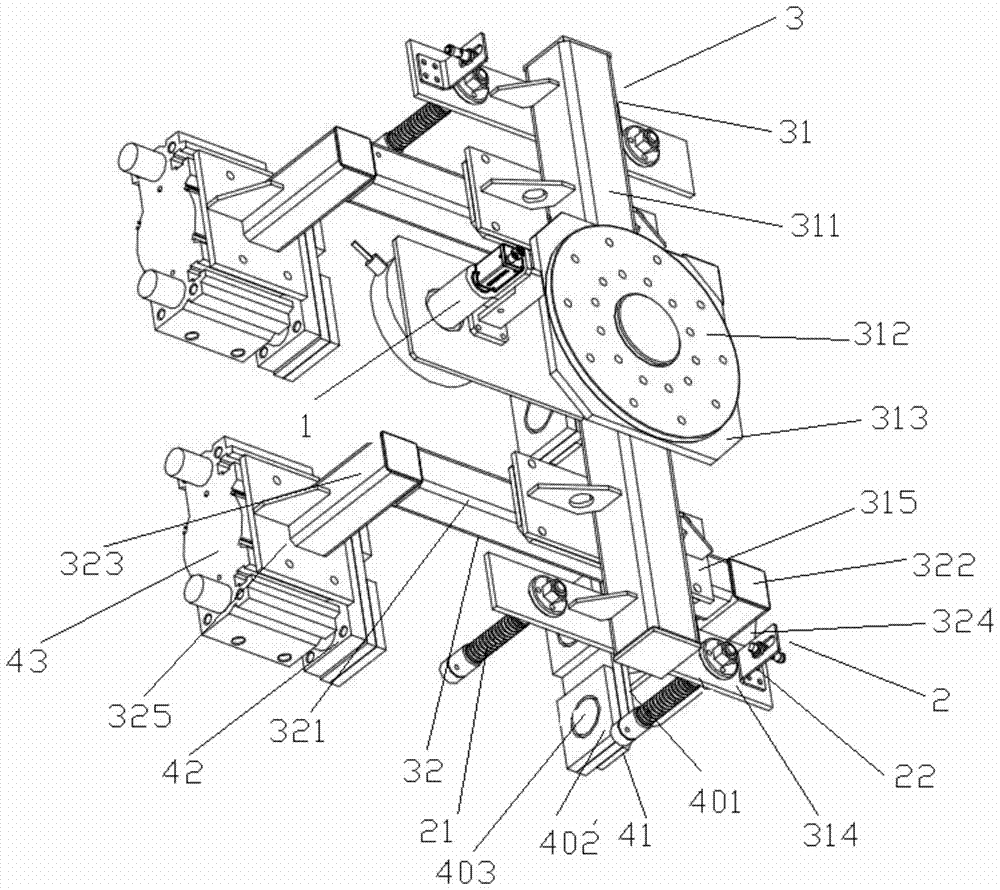

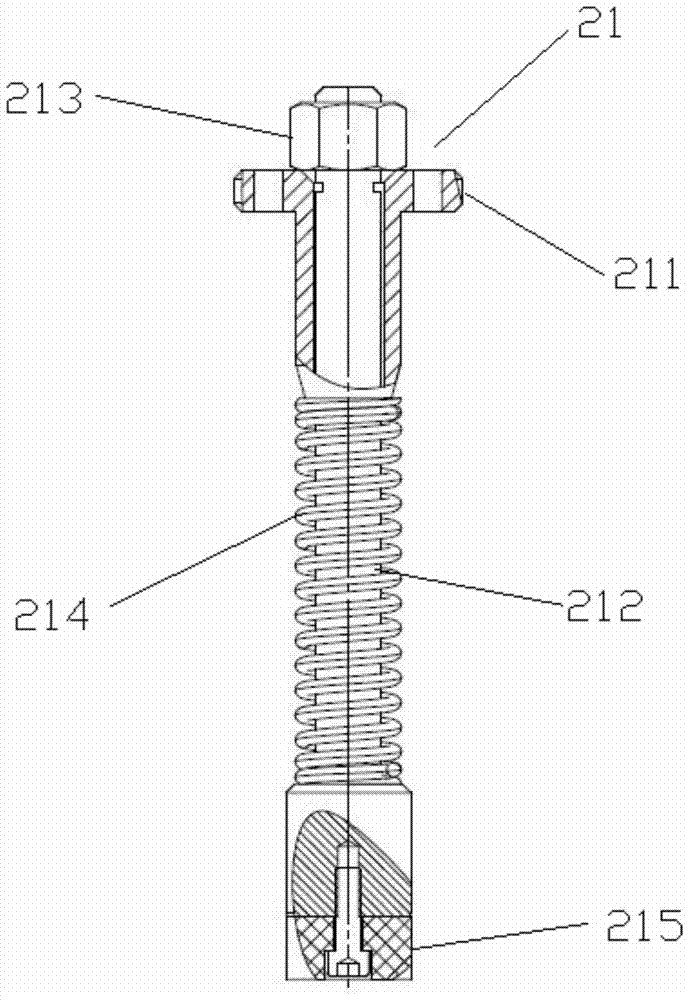

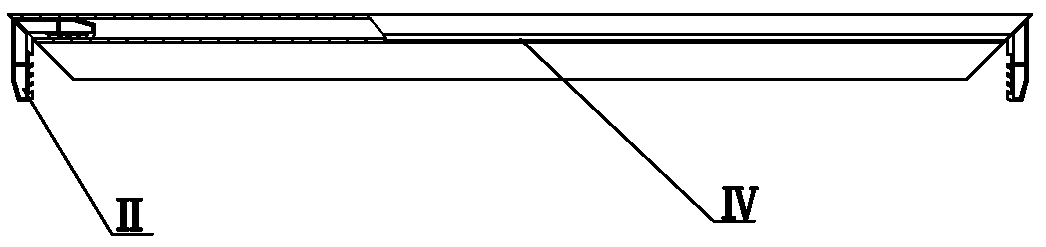

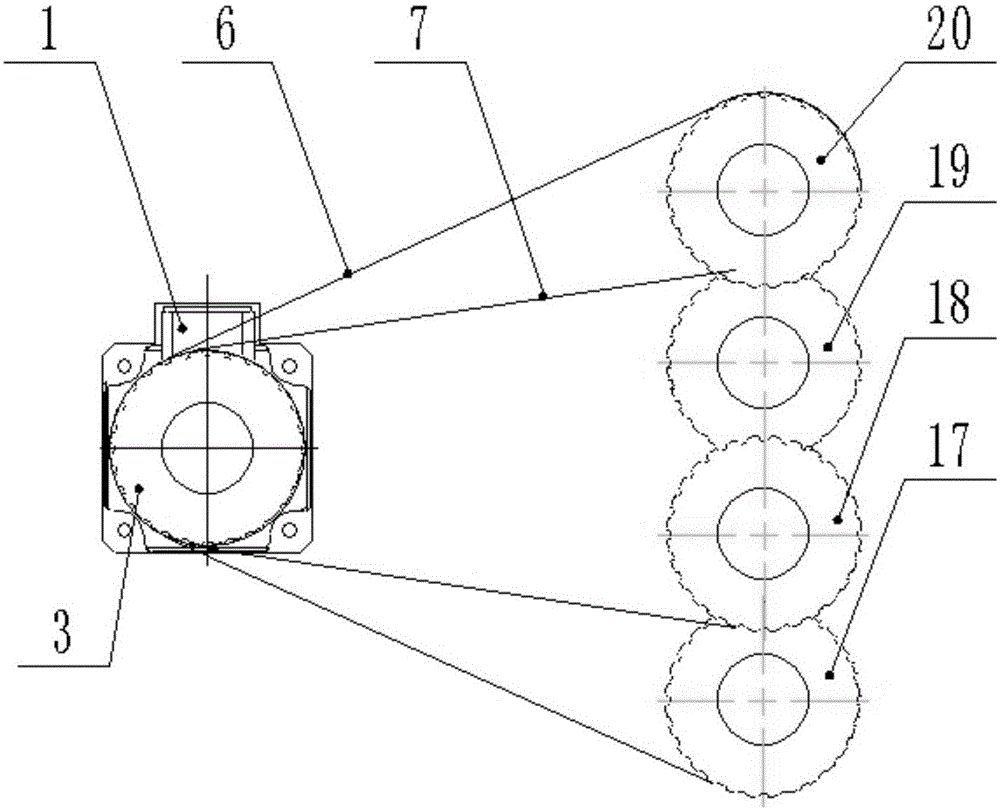

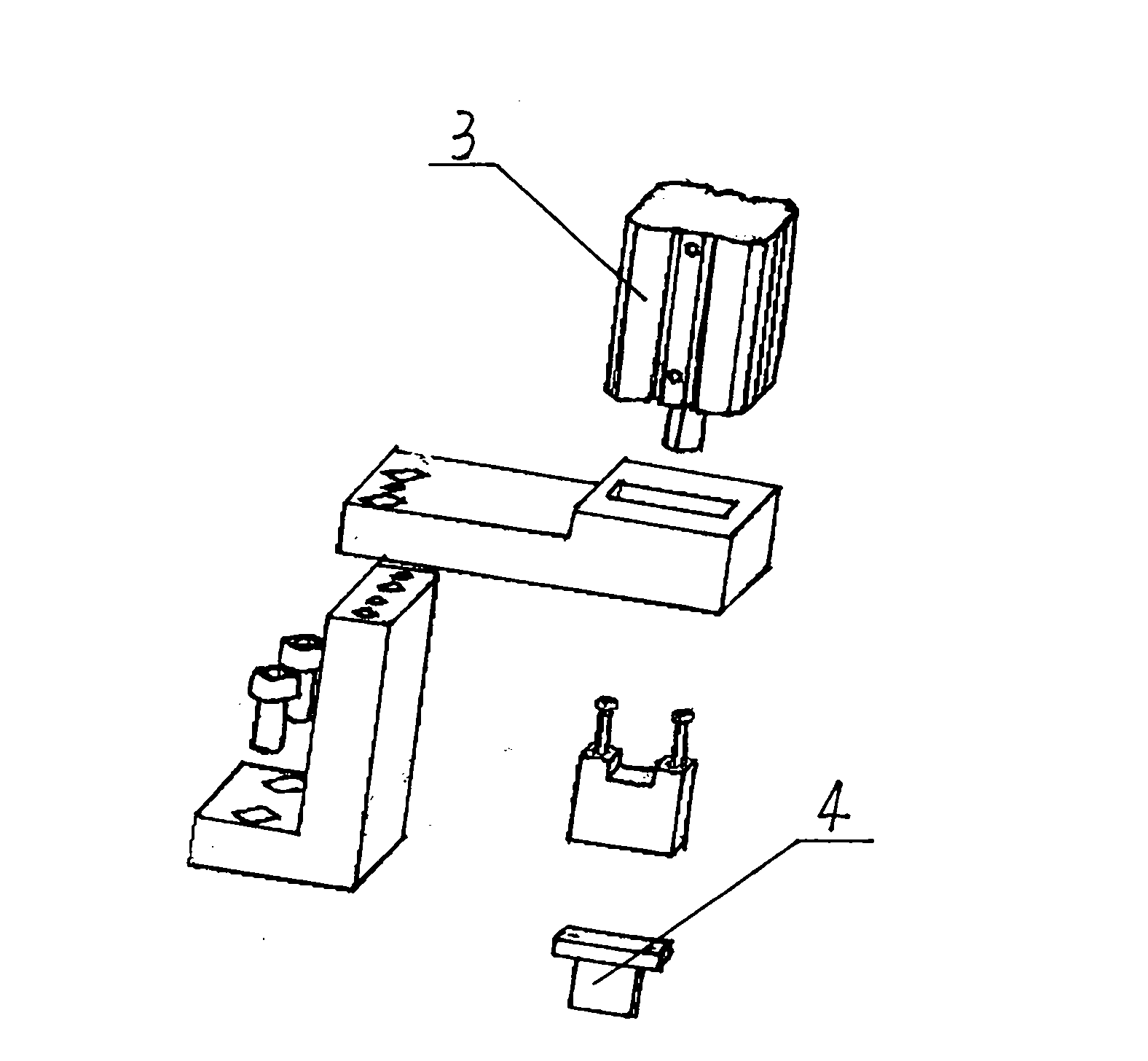

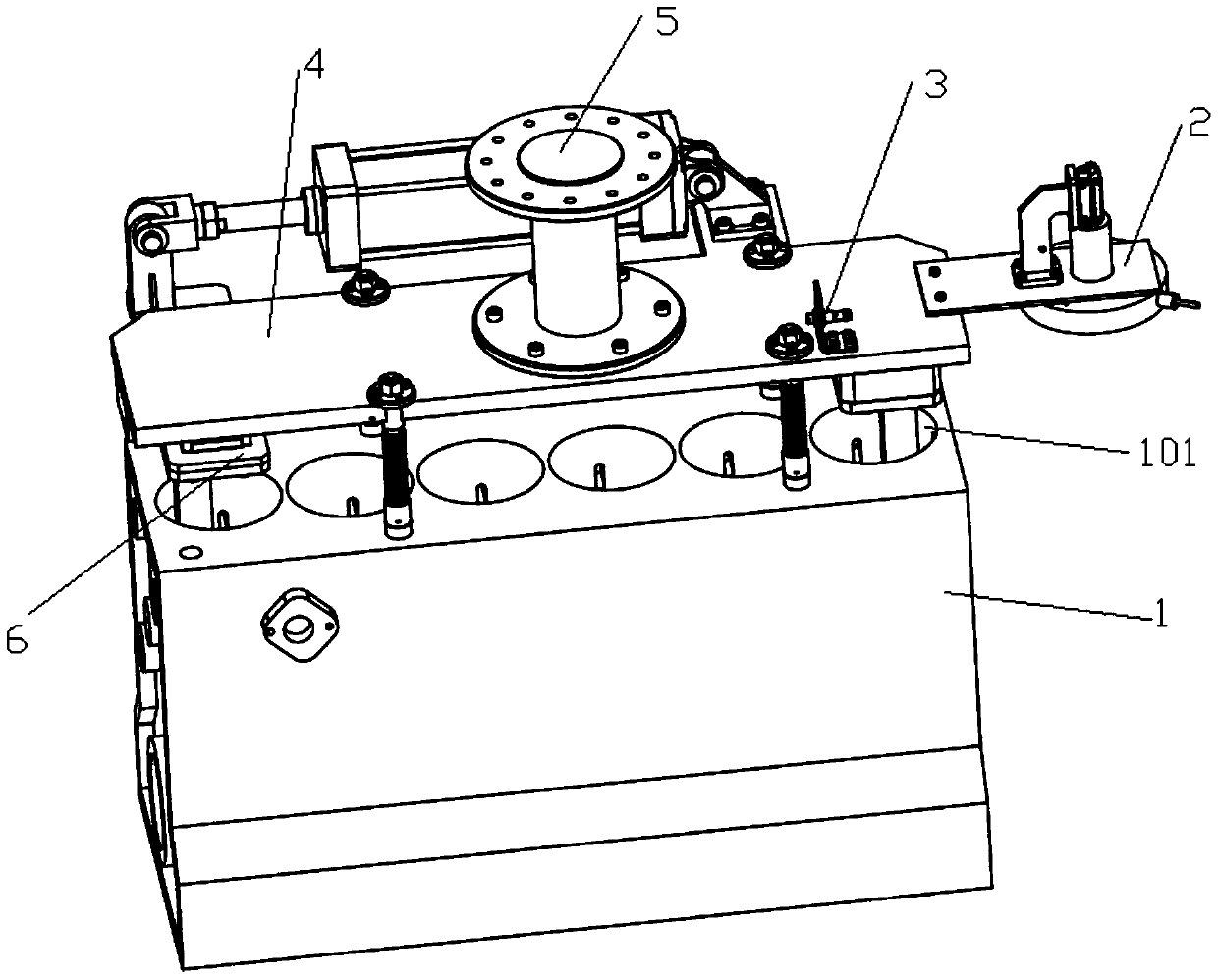

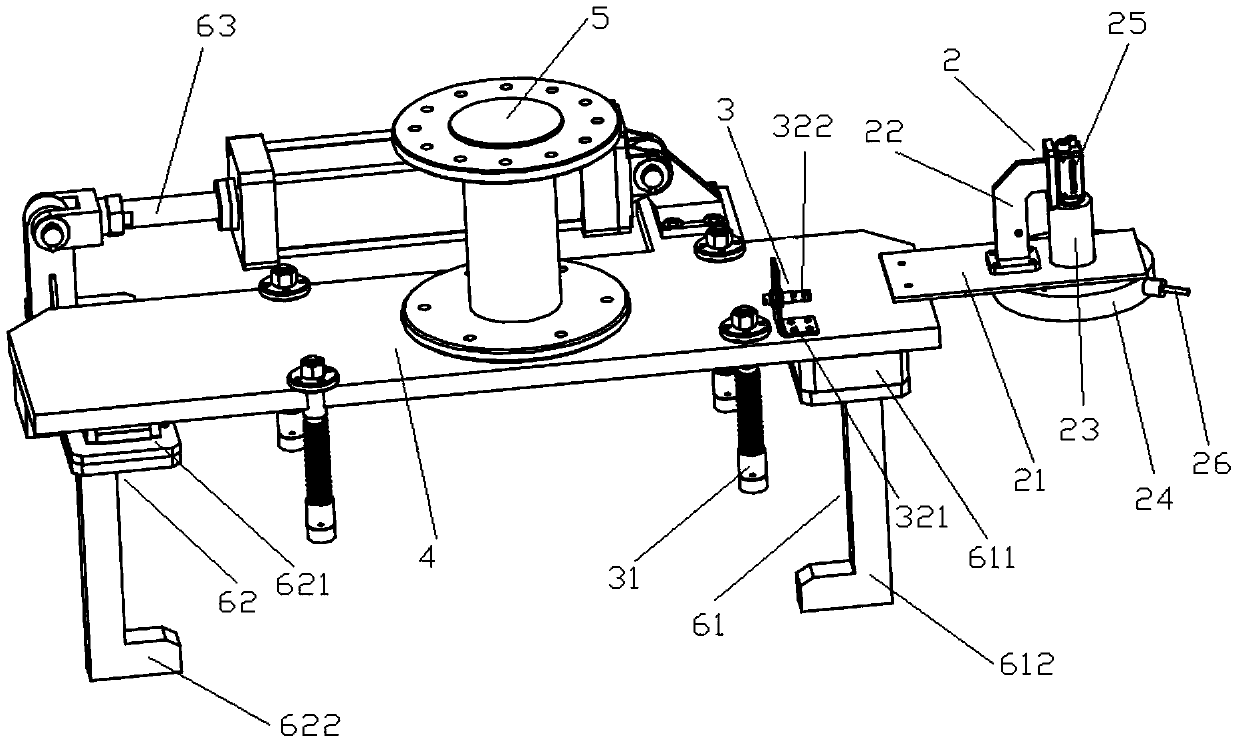

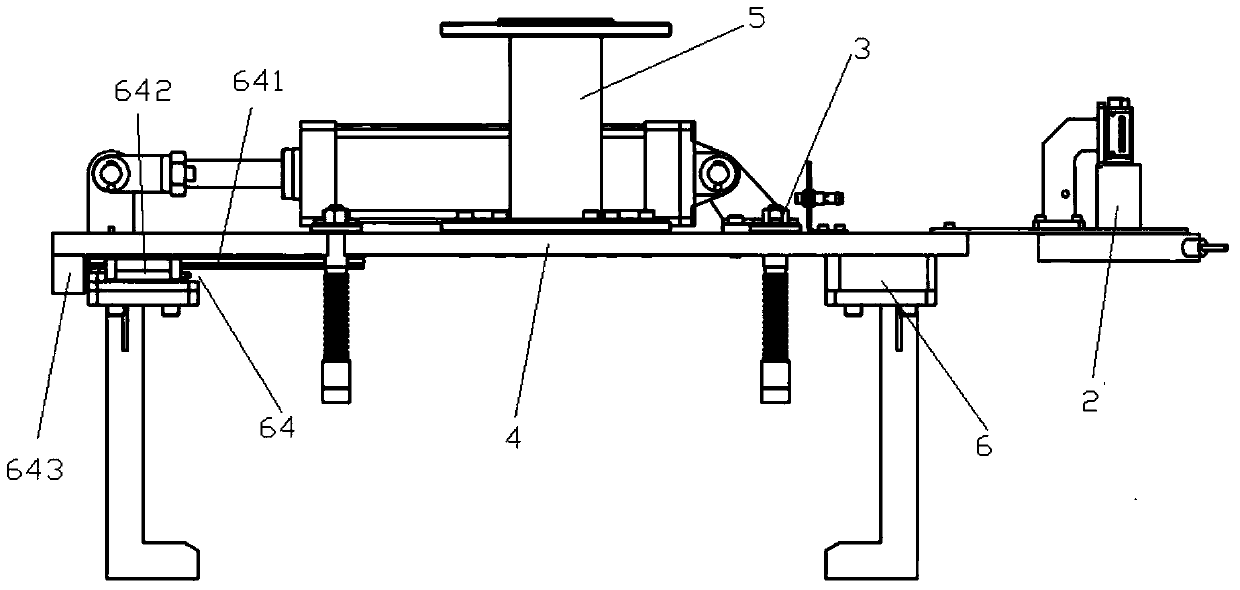

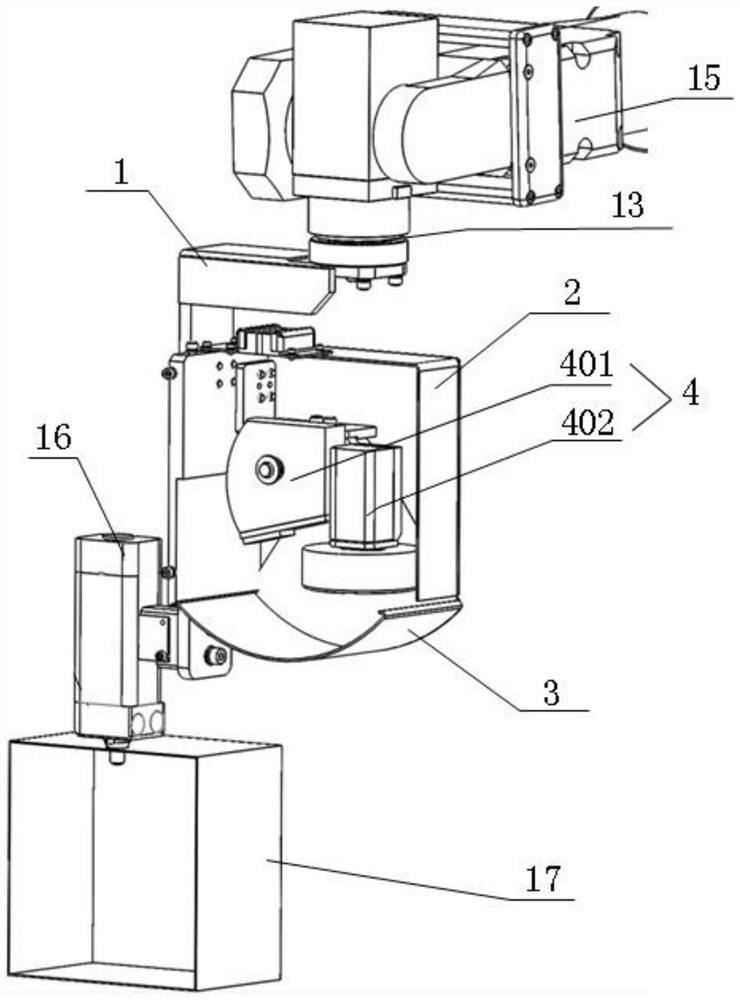

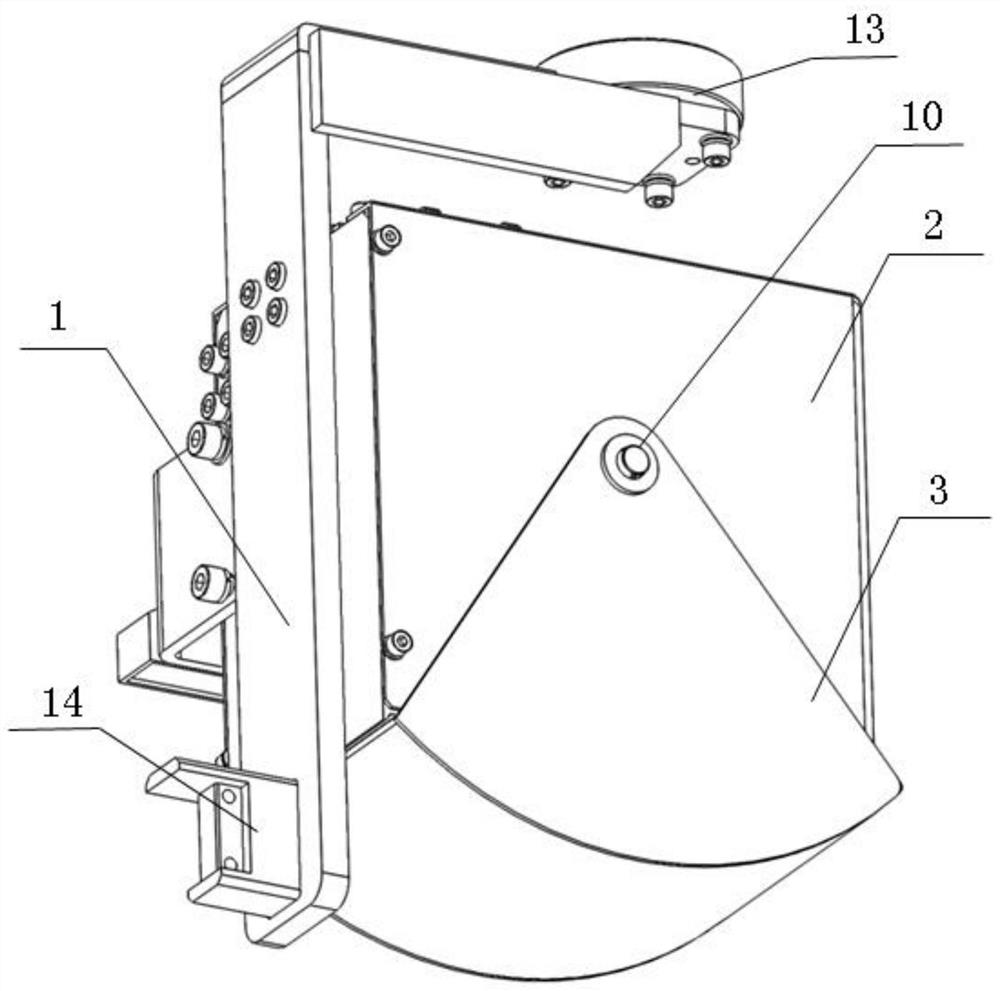

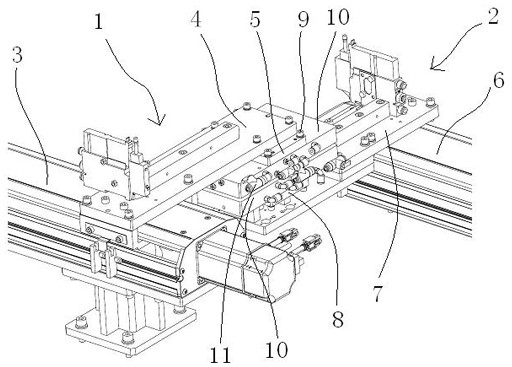

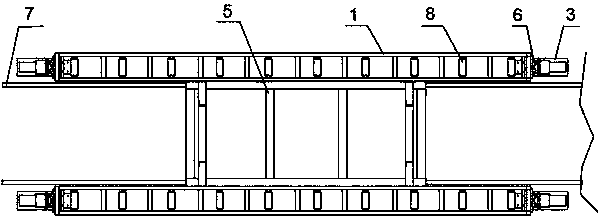

Vision-based robot transfer clamp and system for engine cylinder blocks

ActiveCN105345585AHigh positioning accuracyImprove applicabilityMetal working apparatusControl systemTransfer system

The invention discloses a vision-based robot transfer clamp for engine cylinder blocks. The vision-based robot transfer clamp for the engine cylinder blocks comprises a clamp body which is connected with a transfer robot body. The clamp body is provided with a vision system, a detection system and a pneumatic control system. The vision system, the detection system and the pneumatic control system are all connected with a control system of a transfer robot. The invention further discloses a vision-based robot transfer system for the engine cylinder blocks. The vision-based robot transfer system for the engine cylinder blocks comprises the transfer robot, the robot control system, the vision system, the detection system and the pneumatic control system. The robot control system controls the transfer robot, the vision system, the detection system and the pneumatic control system. Through the robot transfer clamp and the robot control system, automation and intellectualization of cylinder block transfer can be achieved, the transfer efficiency is high, the production cost is low, the transfer safety is high, and the requirement for the takt of robot machining can be met.

Owner:CHANGSHA CTR ROBOTICS

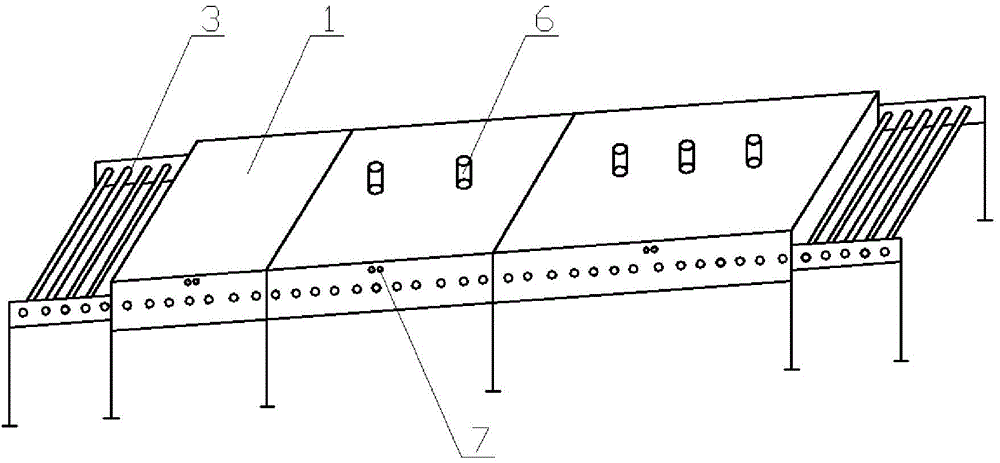

Heat stamping forming board heating furnace

The invention discloses a heat stamping forming board heating furnace. The board heating furnace comprises a furnace wall and conveying rollers for conveying a heated board. A board input opening and a board output opening are formed in the front end and the back end of the furnace wall respectively; and the conveying rollers are driven by an external driving system to rotate so as to convey the board. The furnace wall and furnace interior space defined by the furnace wall are sequentially divided into an induction area and a radiation area in the direction of board conveying. A partition board is arranged between the induction area and the radiation area, and a partition board channel is arranged in the middle of the partition board; the induction area is provided with a supporting part, an induction coil and a heating controller; the radiation area is provided with radiation pipes; and protection gas connection pipes are arranged on the furnace wall. The board heating furnace has the advantages that the board on the heat stamping forming production line is fully austenitized, and meanwhile the requirements for the continuous production takt and energy saving are met; the quality of heat formed products and quality stability are ensured; and heating efficiency is improved; and the heating period is shortened, and the heat energy loss is reduced.

Owner:武汉钢铁有限公司

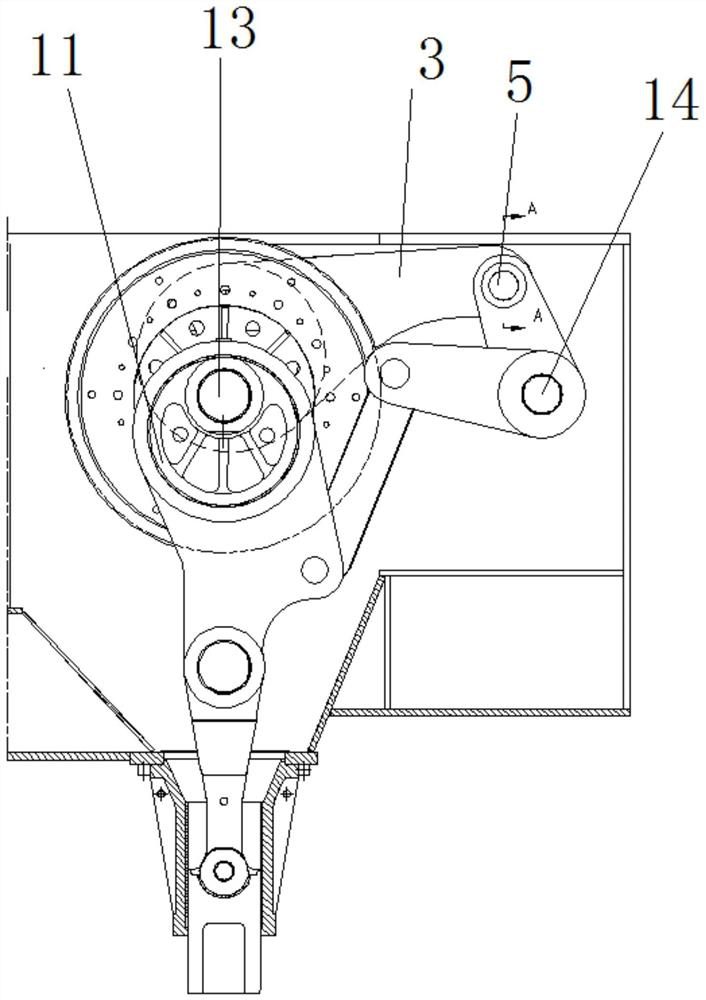

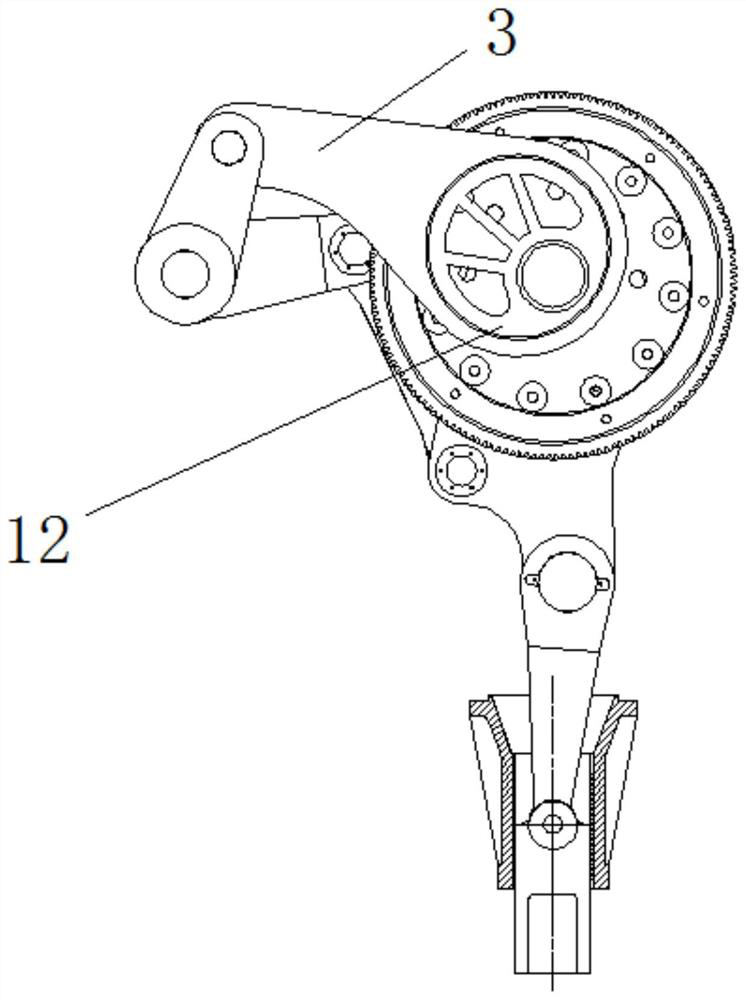

Main driving motor support structure for electromobile

InactiveCN103552449AImprove reliabilityThe overall structure is simple and reliableElectric propulsion mountingPropulsion coolingElectric machineryEngineering

The invention provides a main driving motor support structure for an electromobile. The main driving motor support structure comprises a suspension support body, a support post and a suspension transition support; the main driving motor support structure also comprises a driving motor body; a boss is designed at the upper part of a front end cover of the driving motor body; an enclosing coolant gallery is arranged at the periphery of the driving motor body; a boss structure is also designed at the position, close to a rear end cover of the driving motor body, above the enclosing coolant gallery; the suspension support structure has a very strong portability and is suitable for a power assembly system formed by motors and transmissions with different sizes.

Owner:SHENYANG INST OF ENG

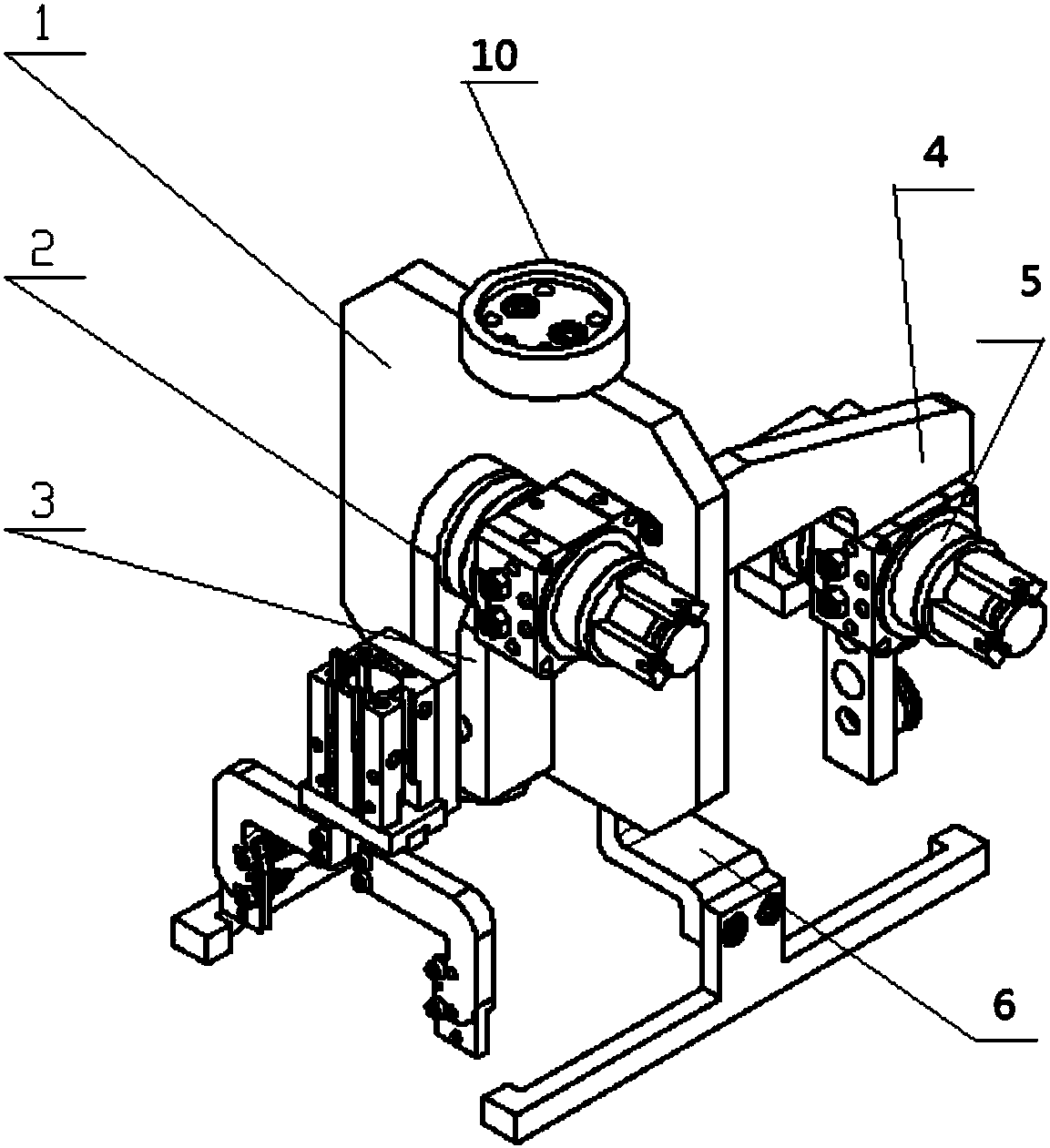

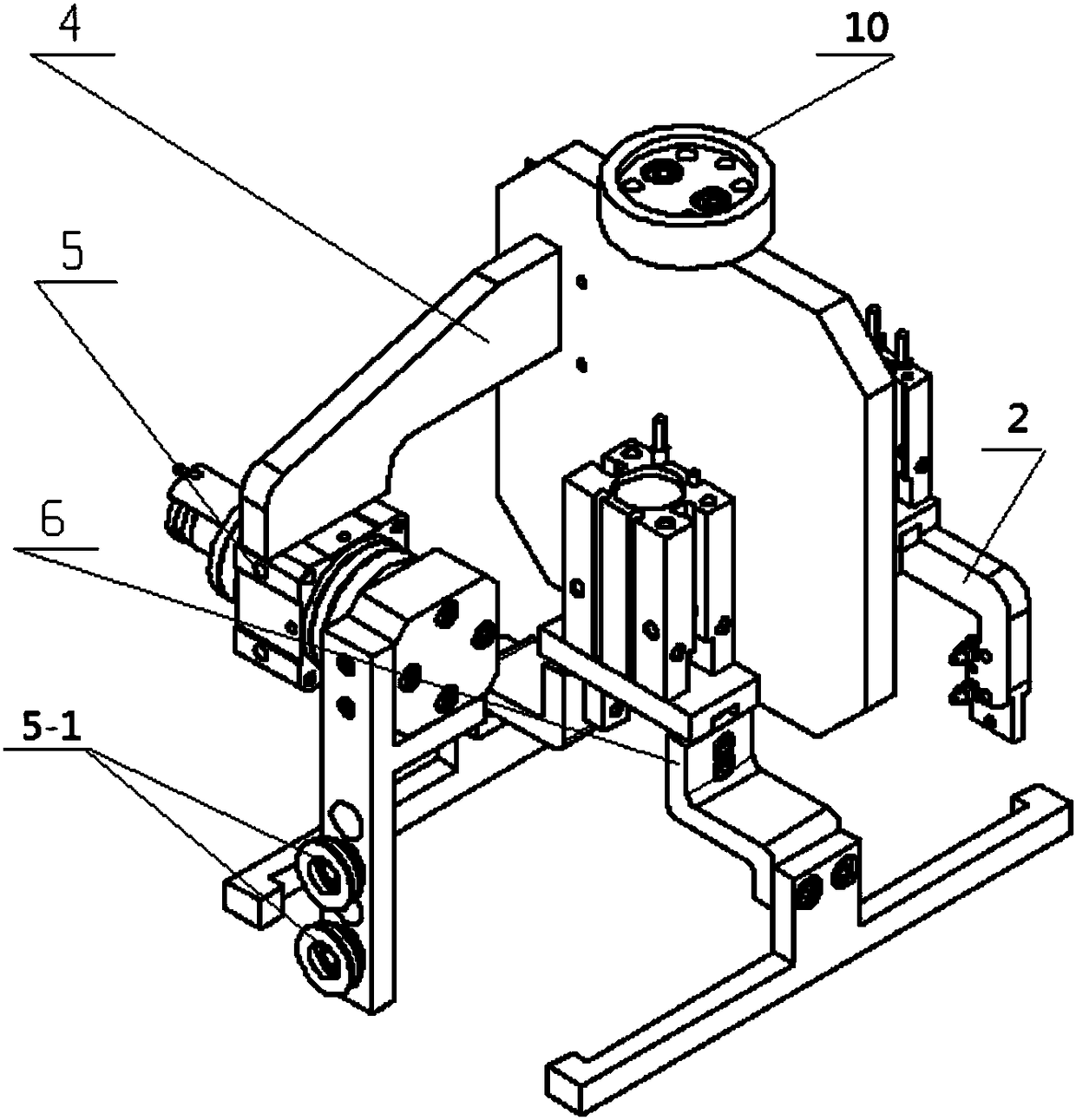

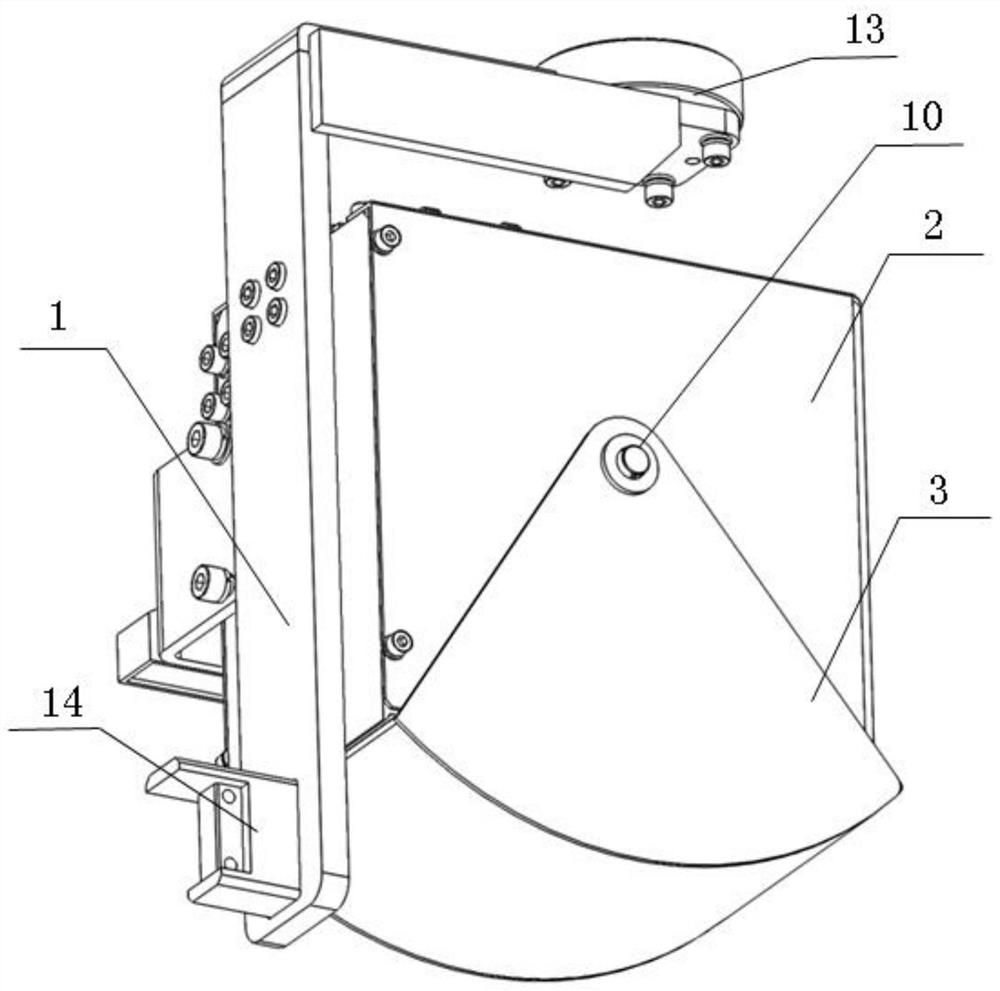

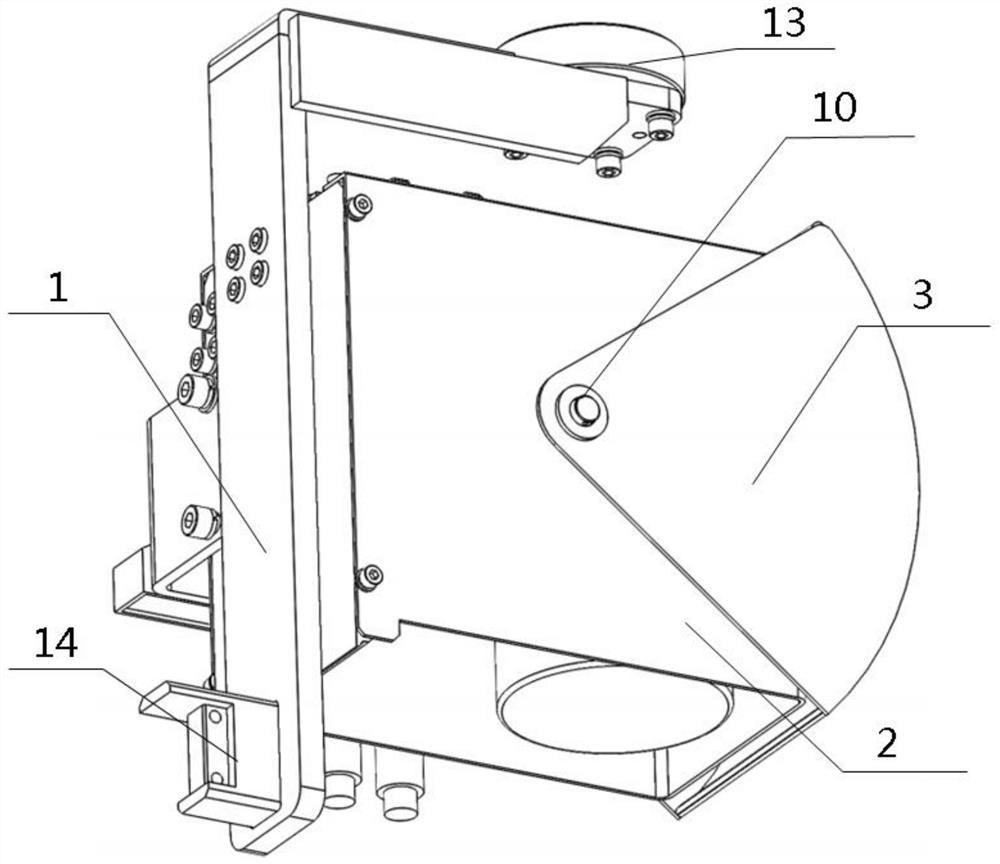

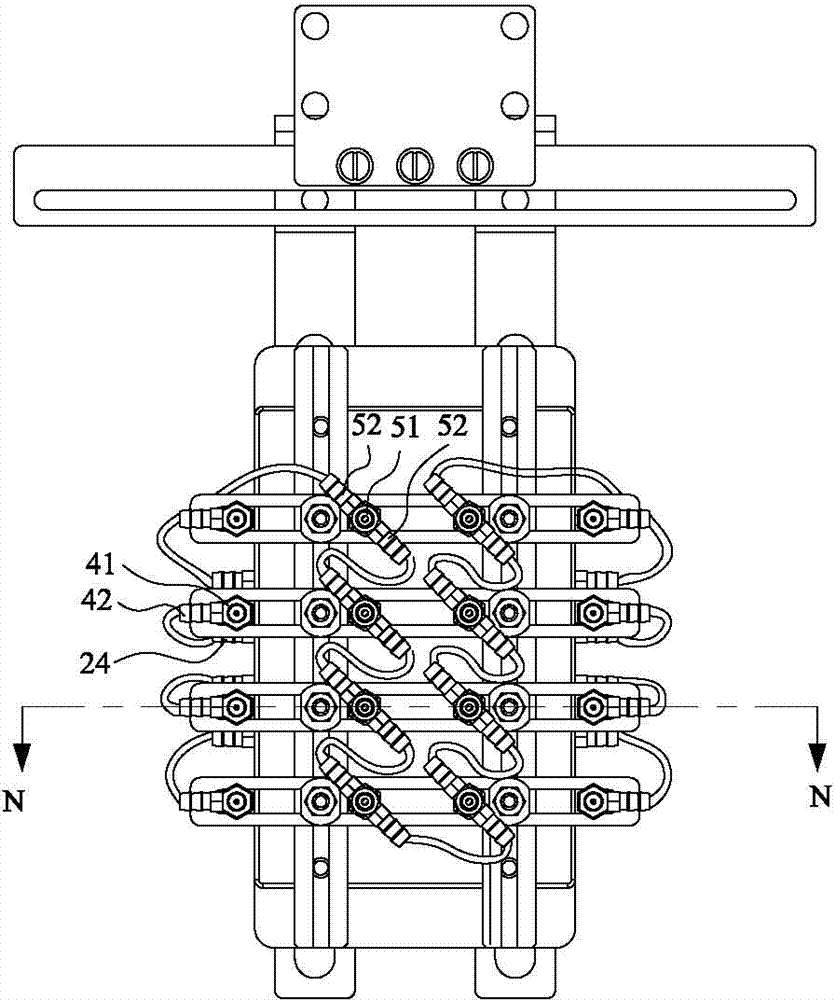

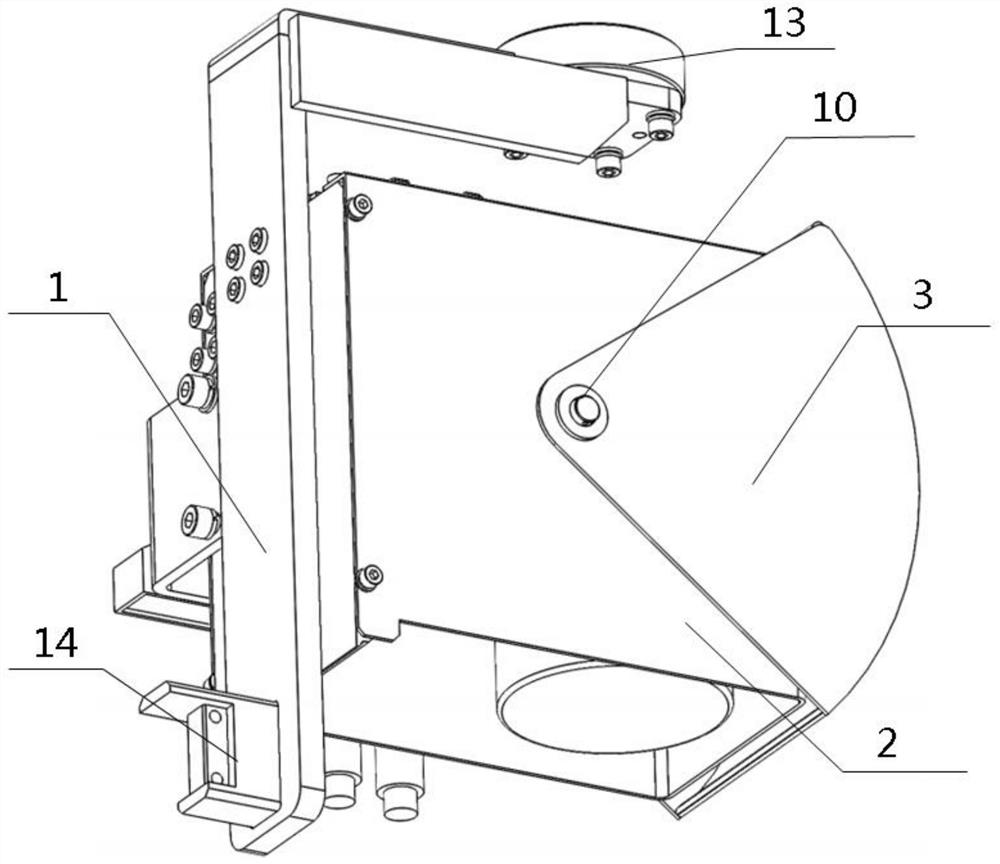

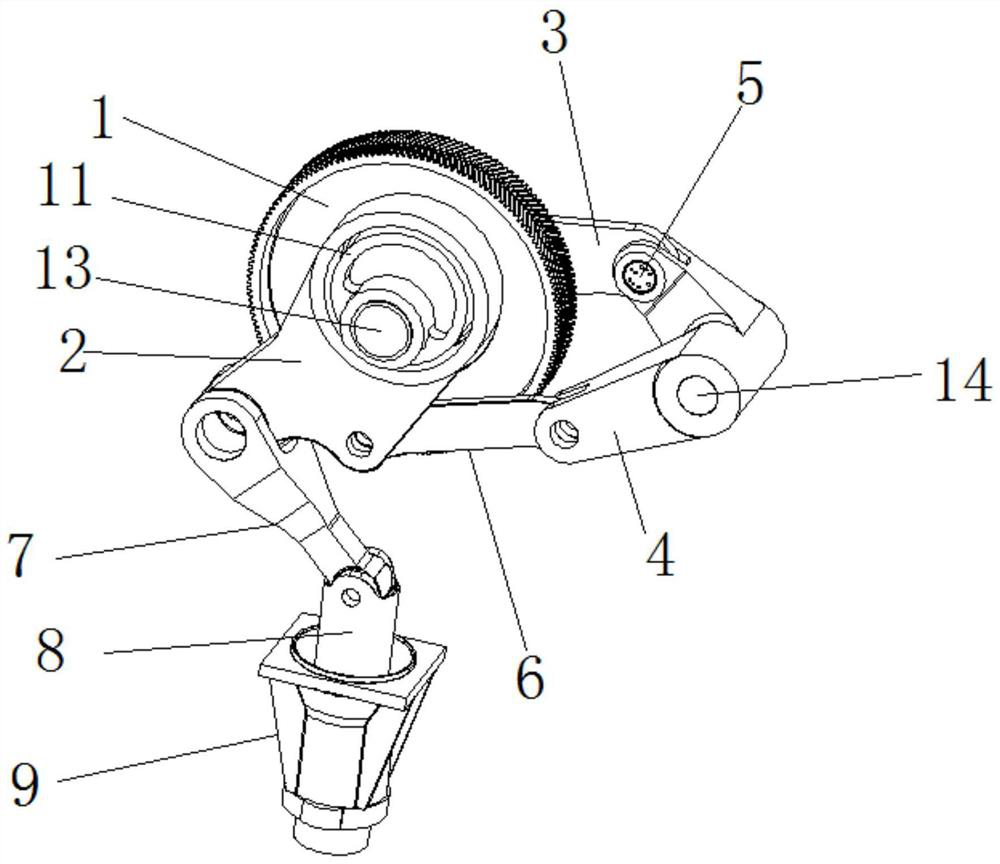

Feeding-discharging and glass detection manipulator of hot bending machine

InactiveCN108340390AMeet the beat requirementsMeet location needsGripping headsManipulatorCantilever

The invention discloses a feeding-discharging and glass detection manipulator of a hot bending machine, and relates to manipulators for hot bending machine off-line die circulation and glass defect detection. The manipulator of the hot bending machine solves the problems that the existing hot bending machine off-line circulation work can only be completed through manual operation, and manual operation for a long period of time can generate fatigue. The manipulator comprises a body, a manipulator connecting body, a clamping assembly, a cantilever support, a suction assembly and a grabbing assembly, wherein the body is a plate-shaped body, the manipulator connecting body is fixed on the upper end plate edge of the body, the clamping assembly is arranged on one plate surface of the body, andthe cantilever support, the suction assembly and the grabbing assembly are arranged on the other plate surface of the body. According to the feeding-discharging and glass detection manipulator of thehot bending machine, the side surface of a glass sheet is clamped by the clamping assembly, so that cleaning work is carried out on the glass sheet; the glass sheet is sucked through the suction assembly, so that conveying work is carried out on the glass sheet is conveyed to work; grabbing, cleaning and positioning of a mold upper cover are completed through the grabbing assembly; and due to thefact that manual operation is replaced, the off-line circulation work only needs 30 seconds or about, and the rhythm requirement of the hot bending machine technology is met.

Owner:爱安特技术(常州)有限公司

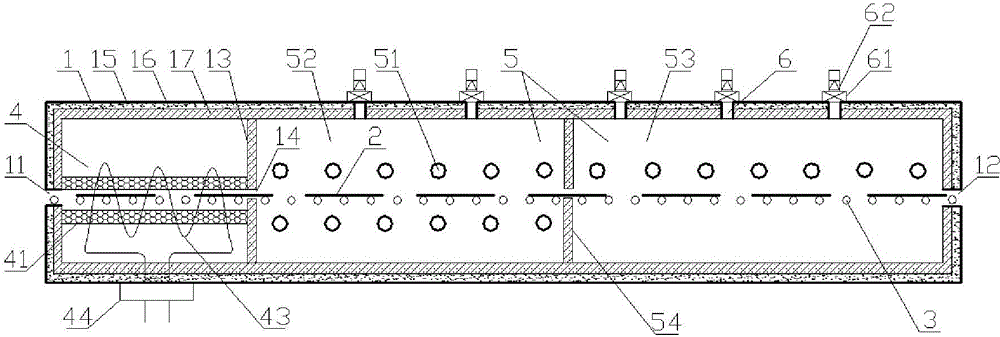

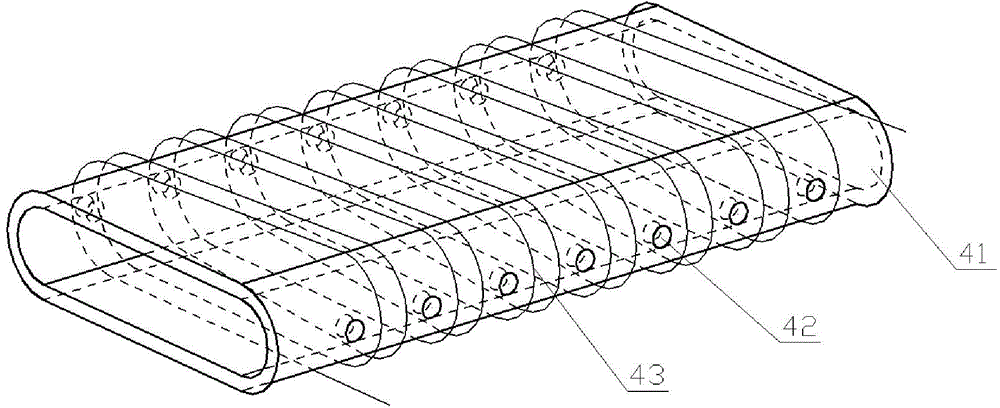

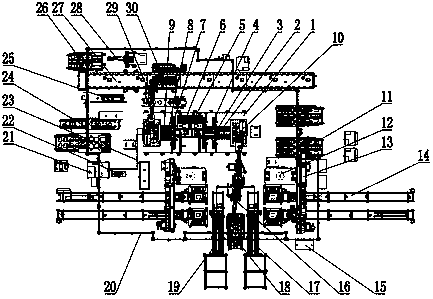

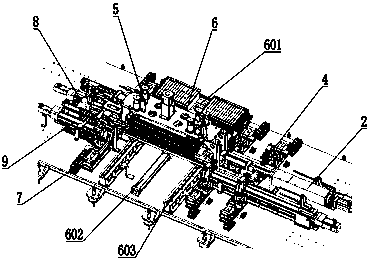

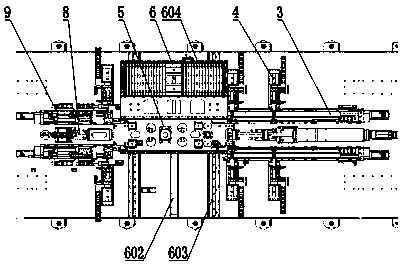

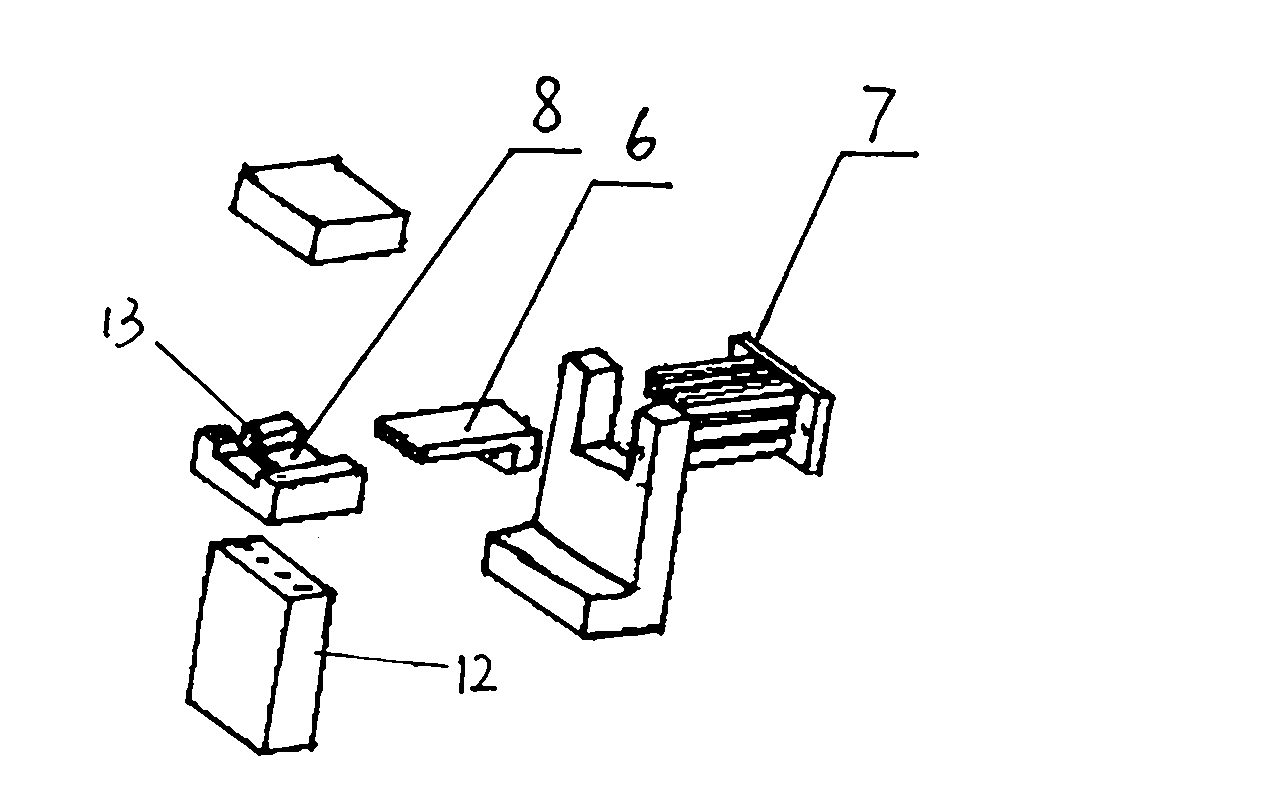

Assembly production line for battery modules

PendingCN110587295AMeet needsIncrease productivityPrimary cell manufactureAssembling battery machinesProduction lineElectrical battery

The invention discloses an assembly production line for battery modules, and relates to the technical field of assembly of the battery modules. The assembly production line comprises an assembly platform. A press-mounting device, a jacking-in device, a bolt receiving and feeding device, a pressing device, a sliding device, a nut receiving and feeding device, a reversely-abutting device, a tightening device, a robot A and a robot D are fixedly mounted on the assembly platform. Various feeding devices and robots are arranged around the outer side of the assembly platform. According to the assembly production line for the battery modules, automatic assembly and production of the battery modules are achieved, long bolts of the modules are automatically assembled, nuts of the modules are horizontally tightened automatically, and motions in different areas are conducted synchronously, so that the production efficiency is improved, and the qualification rate of production is increased; integration of the production steps of grabbing, press-mounting, assembling, tightening and labeling of a single terminal board, a cell unit, a separation plate, a bolt and a nut is realized to obtain a complete battery module; and the automation degree is high, the space is saved, the production takt is accelerated, user requirements are met, the working principle is simple, and using is convenient.

Owner:大连豪森瑞德设备制造有限公司

Cavity automatic foaming visual positioning device and automatic foaming method

The invention discloses a cavity automatic foaming visual positioning device and an automatic foaming method, and belongs to the technical field of foaming process equipment. The cavity automatic foaming visual positioning device comprises a U industrial robot, a fixed cover shell, an industrial camera, a turnover cover shell and a foaming device. The U industrial robot is fixedly connected with afixed support. The fixed cover shell is fixedly arranged on the fixed support. A mounting cavity is formed in the fixed cover shell. An opening is formed in one side of the fixed cover shell. The industrial camera is arranged in the mounting cavity. A lens of the industrial camera faces the opening. The industrial camera is in communication connection with the industrial robot. The turnover covershell is movably connected with one end, provided with the opening, of the fixe cover shell. The turnover cover shell can movably and directly face the opening. The foaming device is fixedly connected with the fixed support. By means of the cavity automatic foaming visual positioning device and the automatic foaming method, automatic foaming operation of a cavity of a vehicle body is achieved, the foaming operation efficiency of the cavity of the vehicle body is improved, the foaming quality is guaranteed, and the harm of foaming operation on health of enterprise employees is avoided.

Owner:SHANGHAI FANUC ROBOTICS

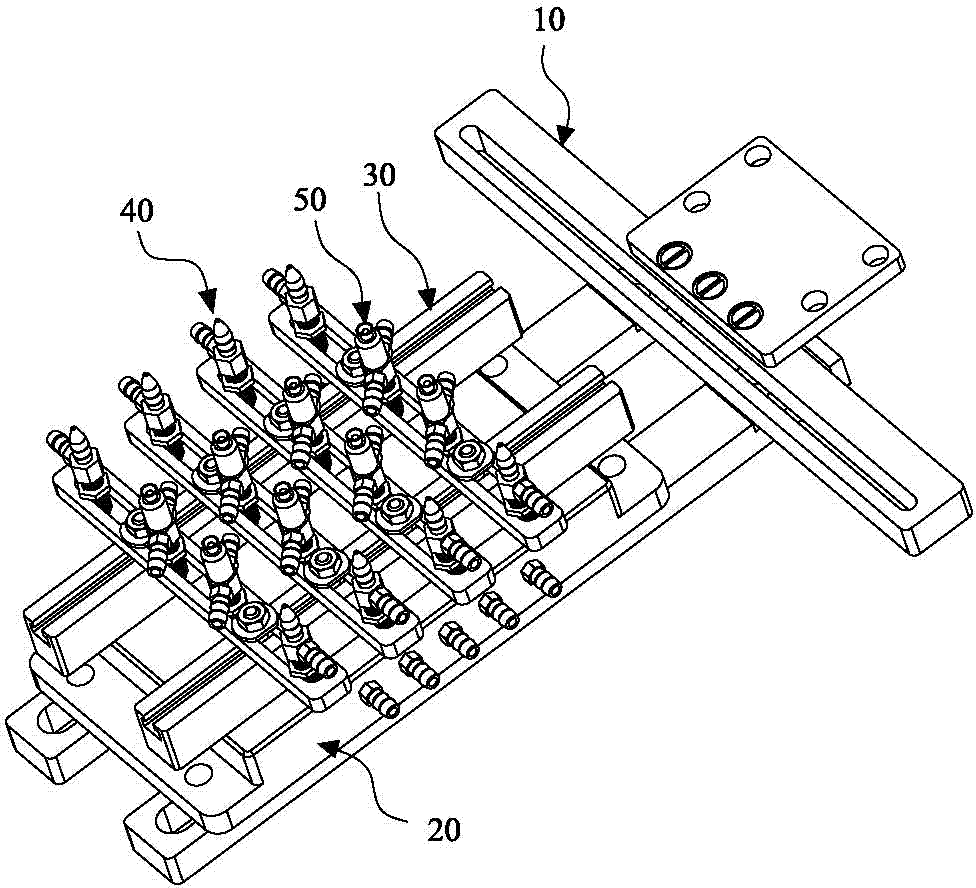

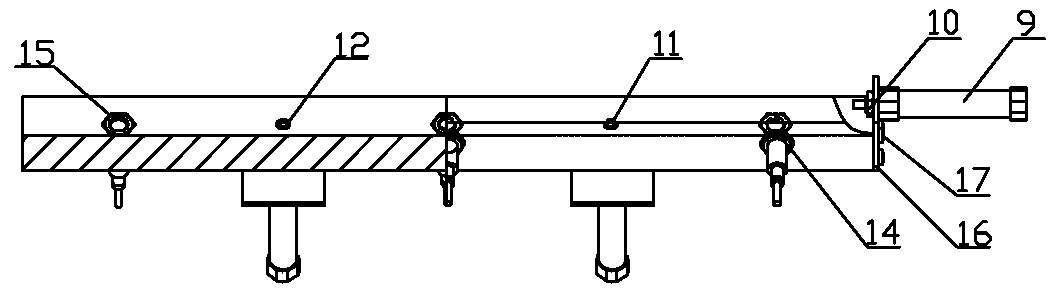

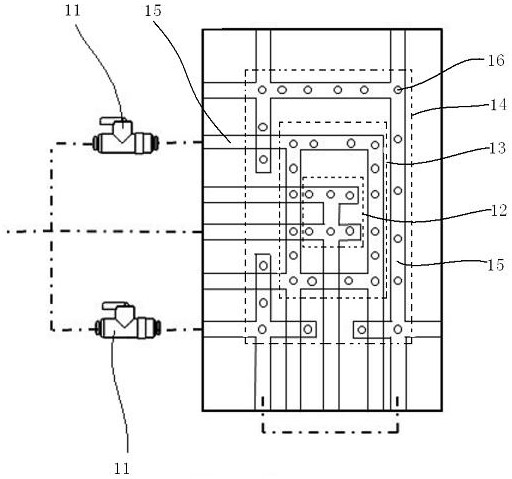

Automatic vacuum suction key fixture

The invention discloses an automatic vacuum suction key fixture which comprises a base, a vacuum suction table, a suction nozzle assembly mounting seat and a plurality of first suction nozzle assemblies and second suction nozzle assemblies. The base, the vacuum suction table and the suction nozzle assembly mounting seat can move along an X axis or a Y axis; the first suction nozzle assemblies are divided into two rows and arranged at two sides of the suction nozzle assembly mounting seat, a first nozzle connector of each of the first nozzle assemblies is correspondingly connected with a first adapter of the vacuum suction table, the second nozzle assemblies are divided into a plurality of rows and arranged at the central part of the suction nozzle assembly mounting seat, and each of the second nozzle assemblies is in series connection with another; and the first nozzles and the second nozzles with different sizes are arranged according to a framework of a product. With such a structure, the automatic vacuum suction key fixture provided by the invention can automatically suck scraps adhered on keys, realizes mechanical automatic removal of the scraps to replace manual labor and improves production efficiency; and two suction nozzles with different sizes enable capacity in sucking scraps on keys to be stronger and a more ideal suction effect to be obtained.

Owner:DONGGUAN MEMTECH ELECTRONICS MEMTECH ELECTRONICS PRO

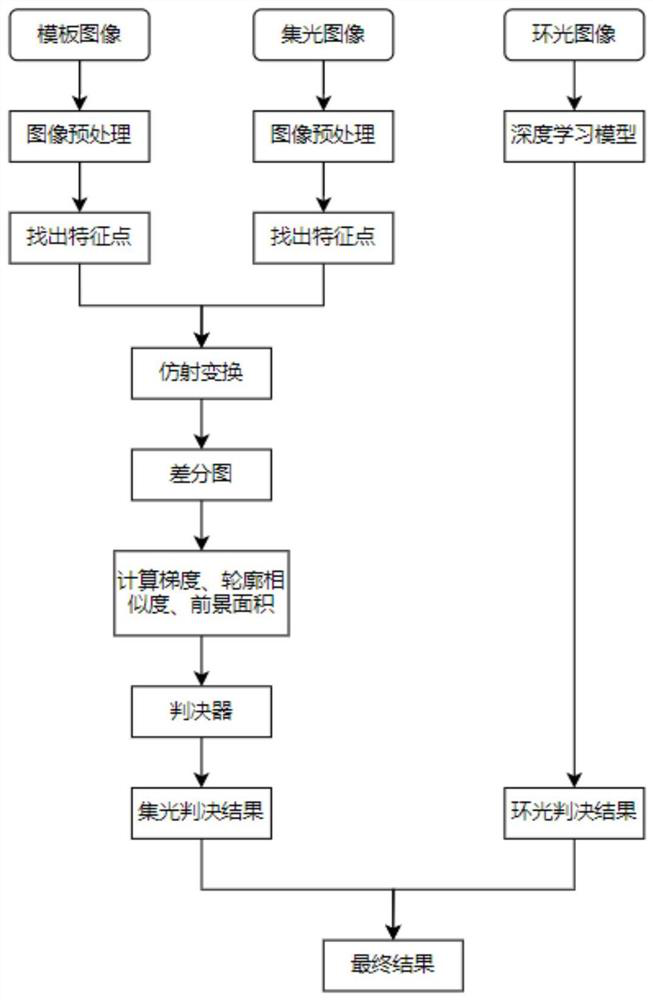

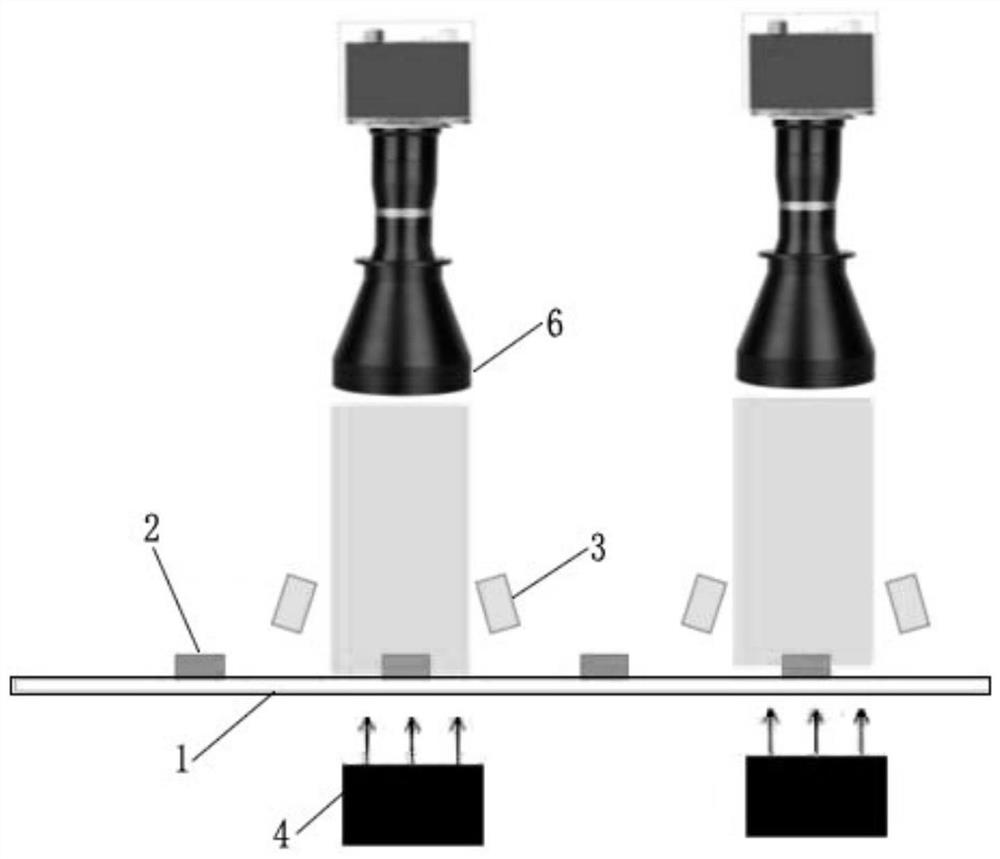

Vision-based medical injection molded part appearance defect detection method

PendingCN114004826AAccurate detectionMeet the beat requirementsImage analysisGeometric image transformationTemplate matchingMedicine

The invention discloses a medical injection molding part appearance defect detection method based on combination of visual template matching and deep learning, and the method comprises the steps: carrying out the photographing and imaging of a to-be-detected medical injection molding part under an annular light source and a collected light source, and obtaining an annular light image and a collected light image of the to-be-detected medical injection molding part; using the deep learning model to carry out defect feature detection of glue shortage, pocking marks and joint lines on the ring light image of the medical injection molding part to be detected, and storing the ring light judgment result of the ring light image; adopting a template matching method for carrying out burr and burr defect feature detection on the light collection image of the medical injection molding part to be detected, and outputting a light collection judgment result of the light collection image; integrating the light-surrounding judgment result and the light-collecting judgment result, and if all the judgment results are qualified, outputting the detection result of the medical injection-molded part to be detected as a qualified product, otherwise, outputting the detection result of the medical injection-molded part to be detected as a defective product. According to the invention, on the premise of ensuring the production takt, unqualified products can be quickly detected, and the treatment time of a single sample is reduced by comprehensively judging and outputting two types of detection results.

Owner:博科视(苏州)技术有限公司

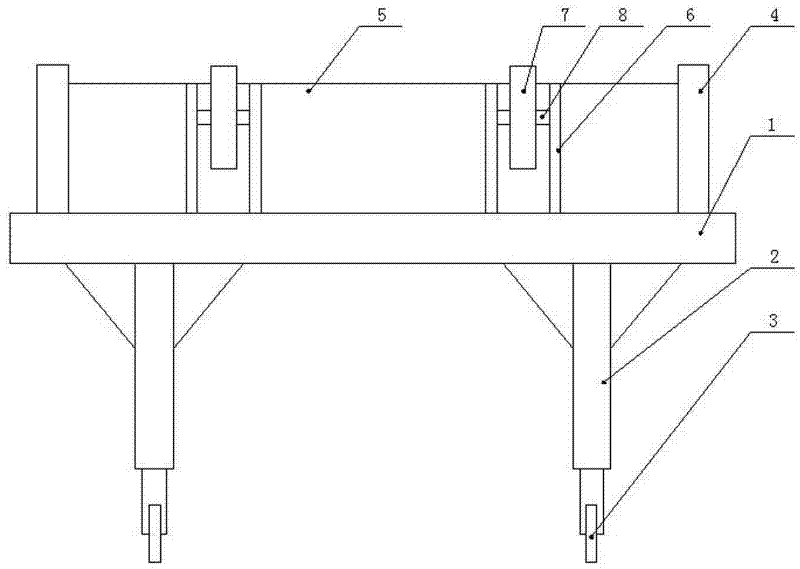

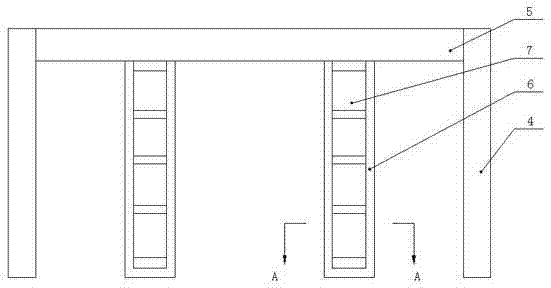

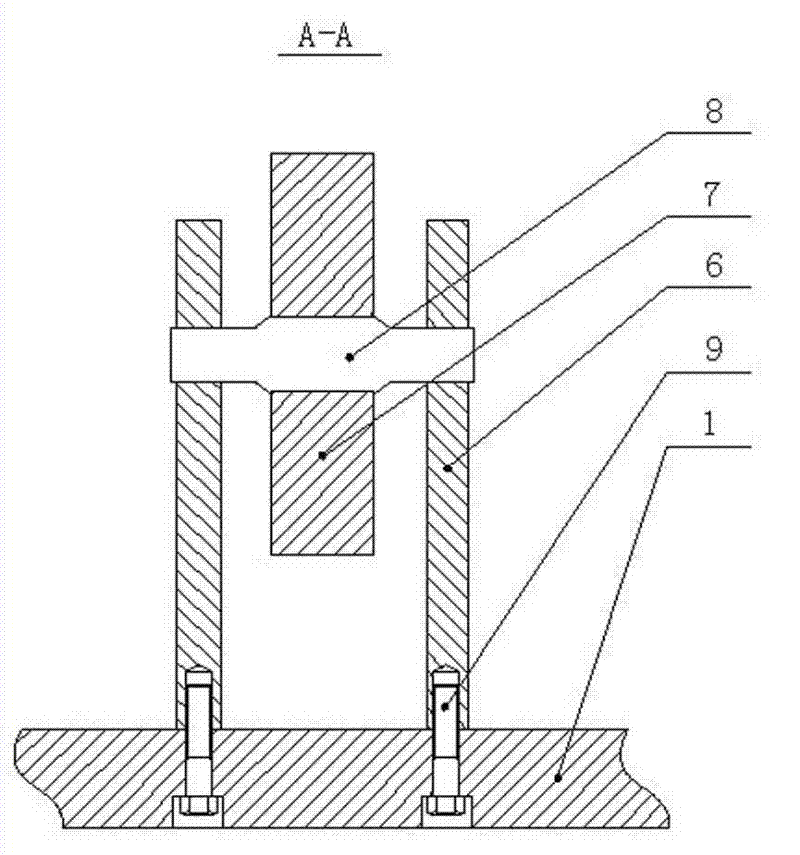

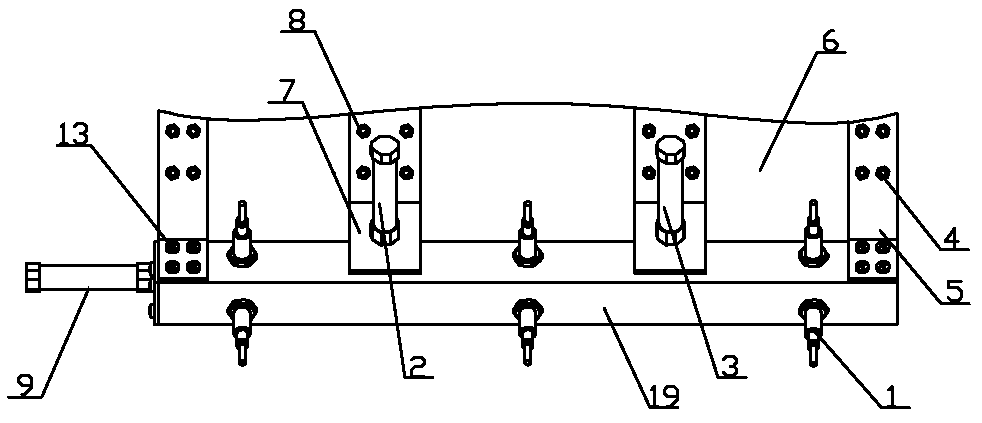

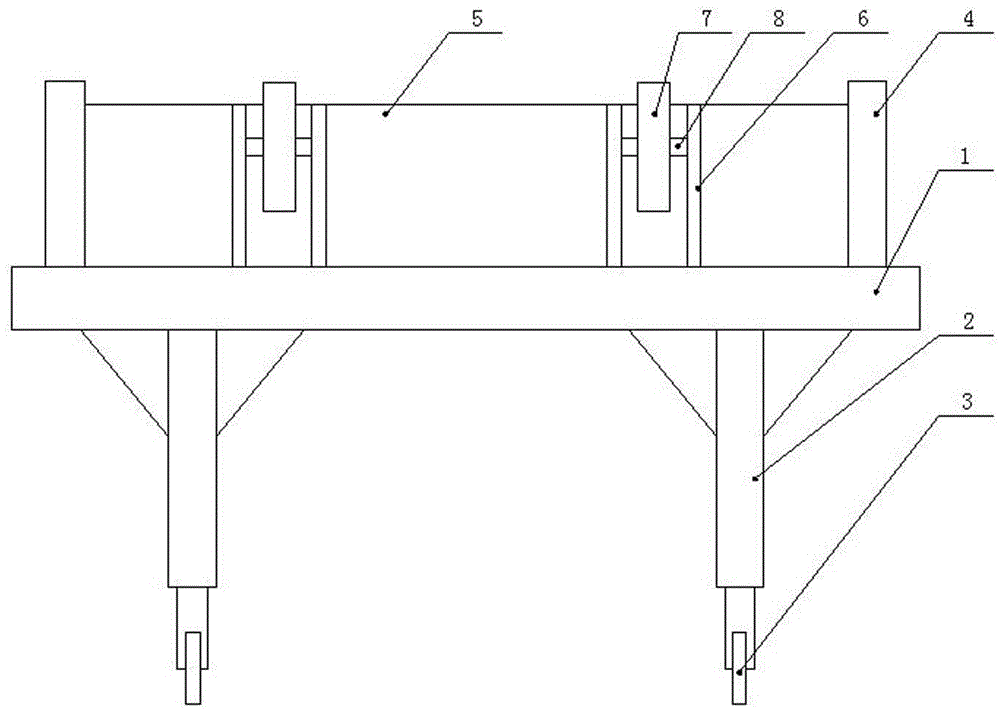

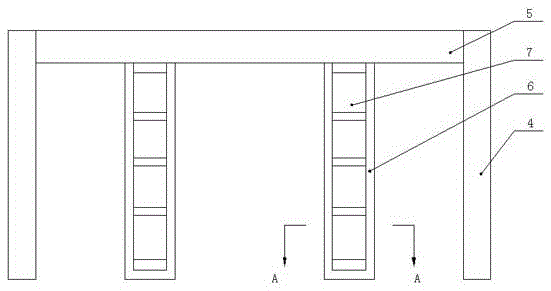

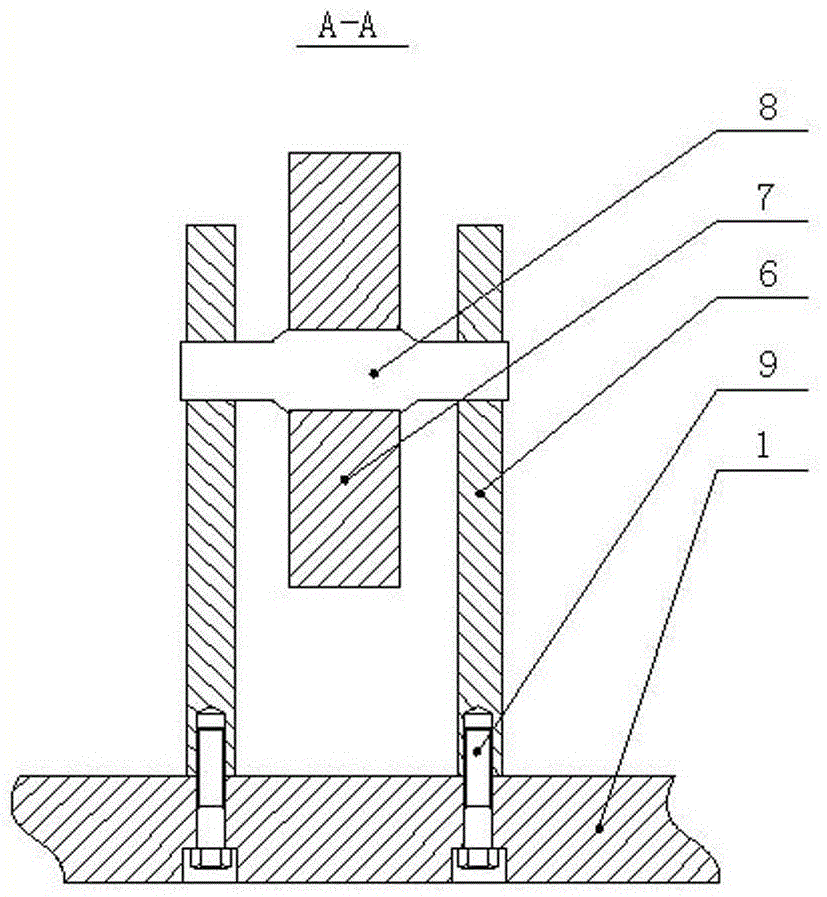

Station device for carrying cylinder cover test piece

The invention discloses a station device for carrying a cylinder cover test piece. The station device comprises a base plate, wherein four brackets are fixedly arranged on the lower surface of the base plate; rotating wheels are arranged at the bottoms of the four brackets; two straight bars and a transverse bar are fixedly arranged on the upper surface of the base plate; two groups of symmetric roller supports which are parallel to the straight bars are fixedly arranged on the upper surface of the base plate by bolts; a plurality of rollers are arranged between the two groups of roller supports; roller shafts of the rollers are in movable fit with corresponding holes in the roller supports; and the upper planes of the rollers are higher than the transverse bar. By the station device, the cylinder cover test piece is convenient to carry quickly; a beat requirement of a production line can be met; and the labor intensity and the safety risk are reduced.

Owner:芜湖火龙动力科技有限公司

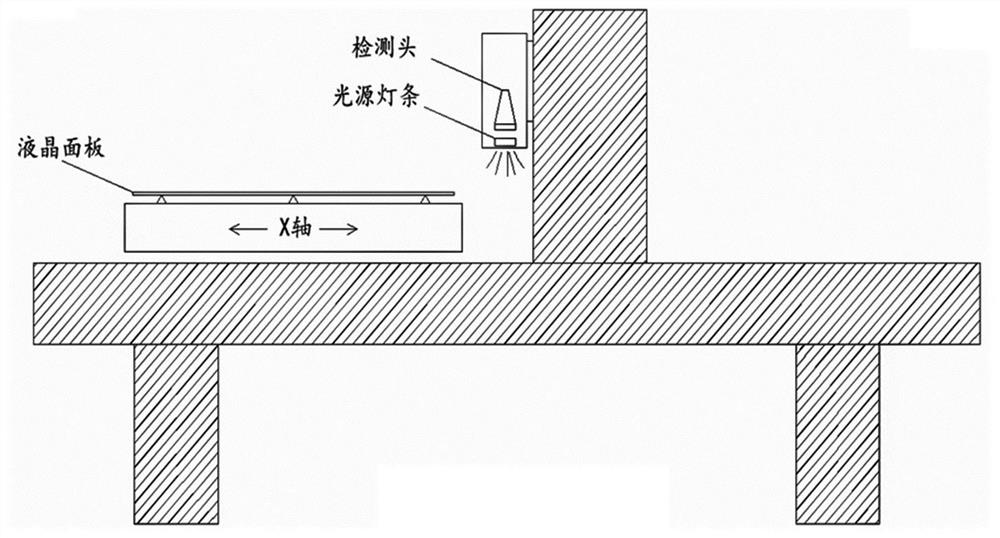

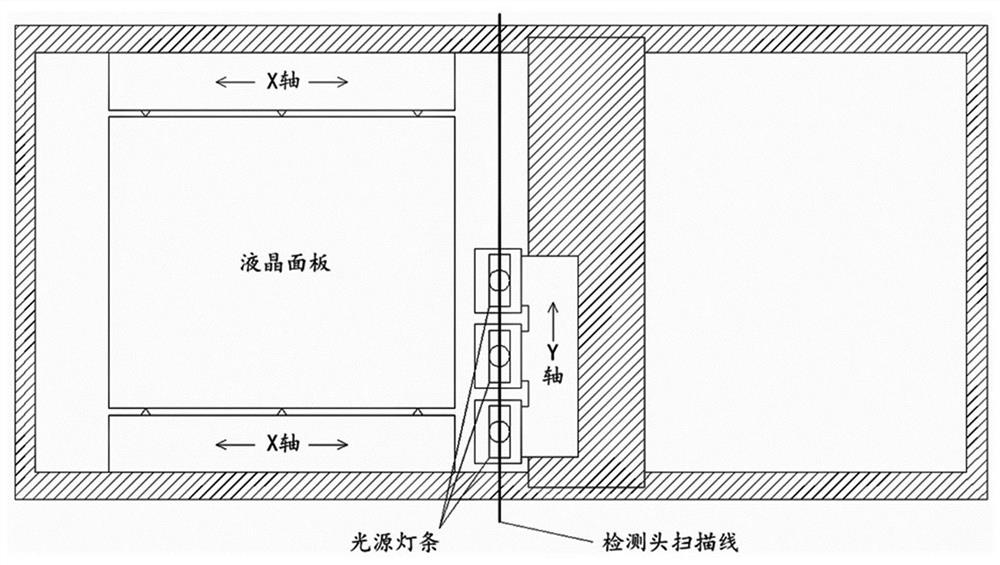

Liquid crystal screen carrying manipulator interfacing apparatus

ActiveCN108508638ASimplify the movement mechanismSmall footprintProgramme-controlled manipulatorNon-linear opticsEngineeringManipulator

The invention relates to a liquid crystal screen carrying manipulator interfacing apparatus, which includes an upper surface detection component and a lower surface detection component. The upper surface detection component is composed of upper sliding telescopic boom, upper fixed arm, upper connection plate and the upper surface detection platform. The lower surface detection component is composed of lower sliding telescopic boom, lower fixed arm, lower connecting plate and lower surface detection platform. The liquid crystal screen carrying manipulator interfacing apparatus simplifies the moving mechanism, reduces the occupied area, omits the transfer manipulator, solves the problem that the background colors is not uniform during detection, and change the suction disc of the detection manipulator into two vacuum adsorption detection platforms, which can meet the requirement of visual detection. And the most important, the freefall docking method achieves rapid and stable handover, saves time, and meets the beat requirement.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

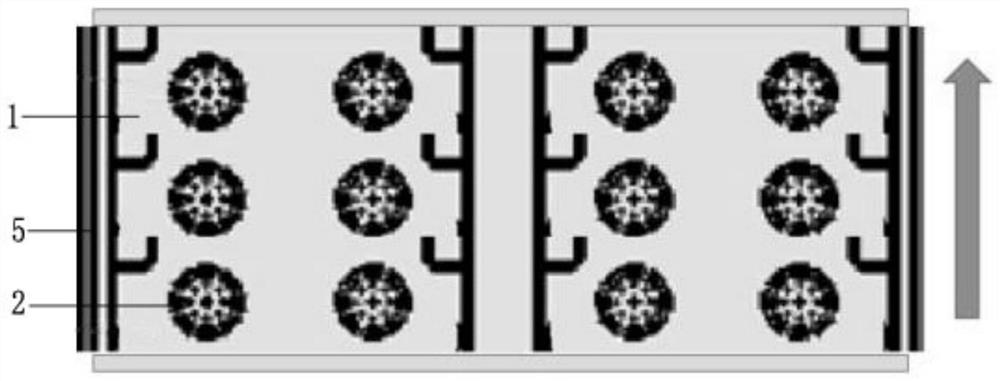

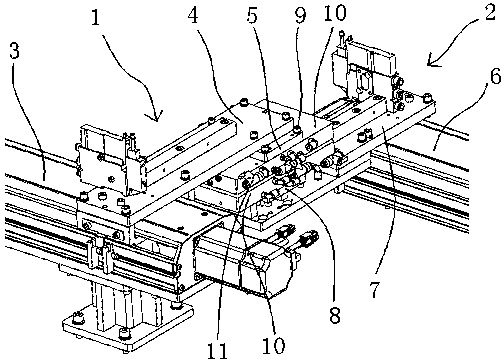

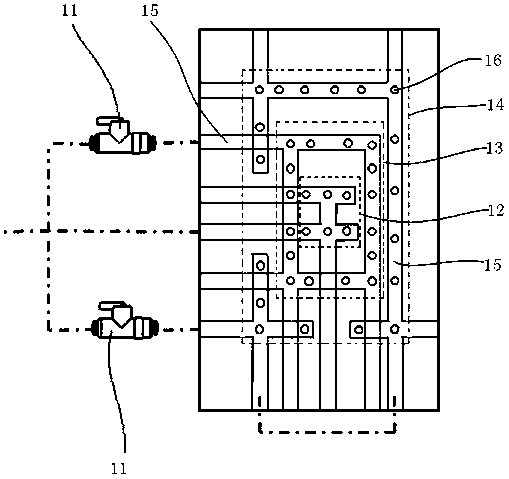

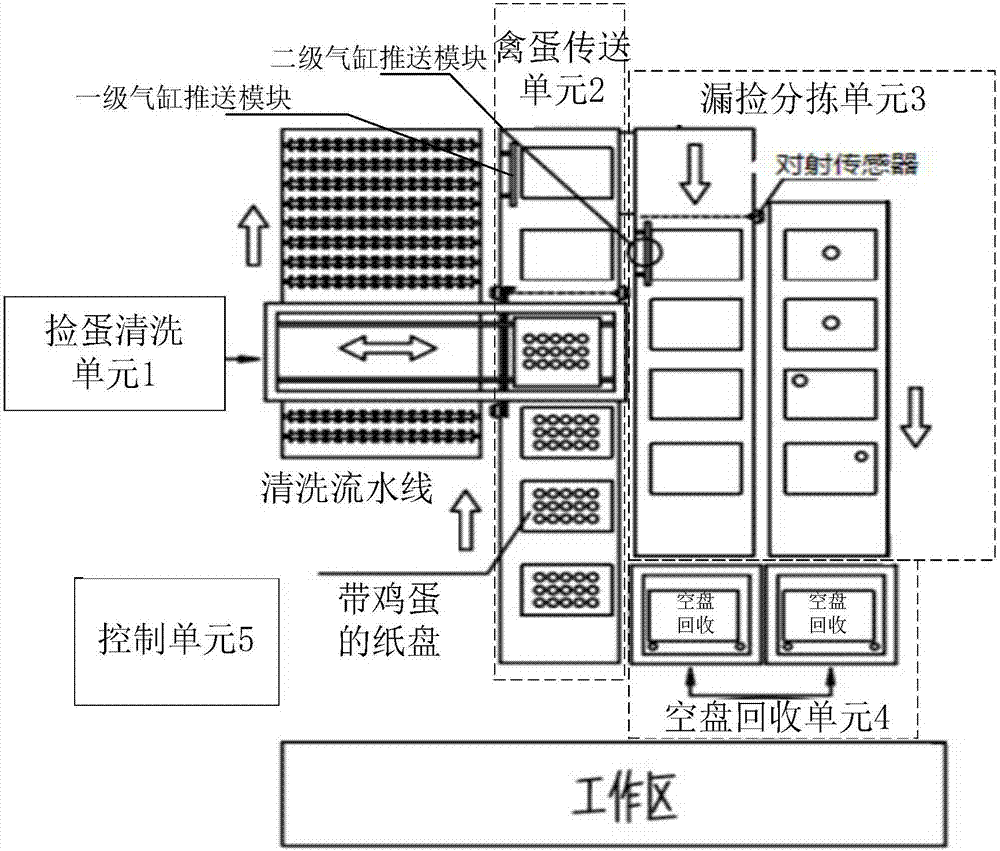

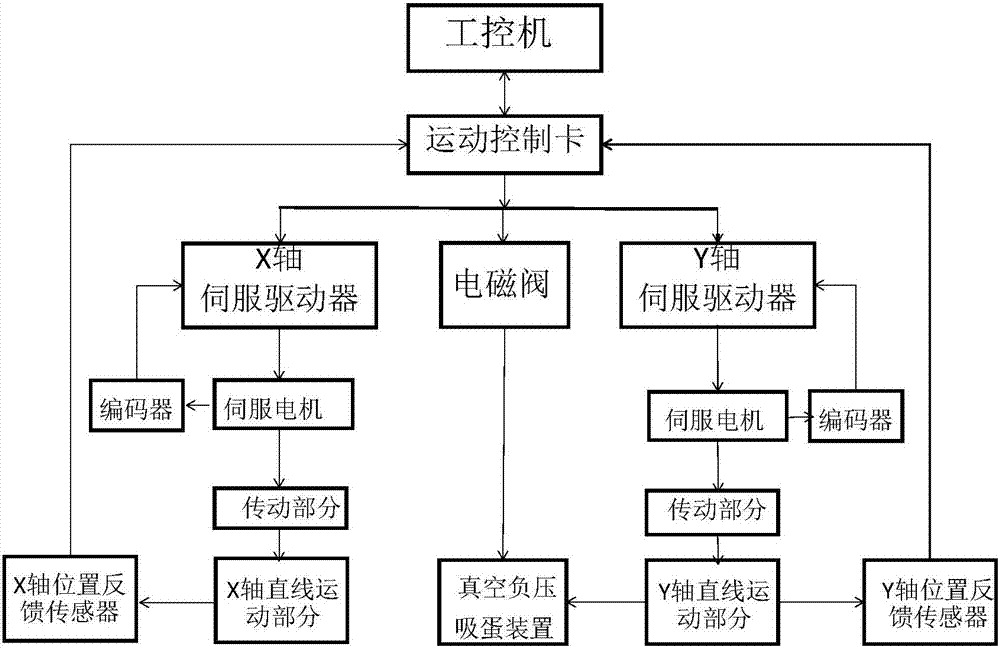

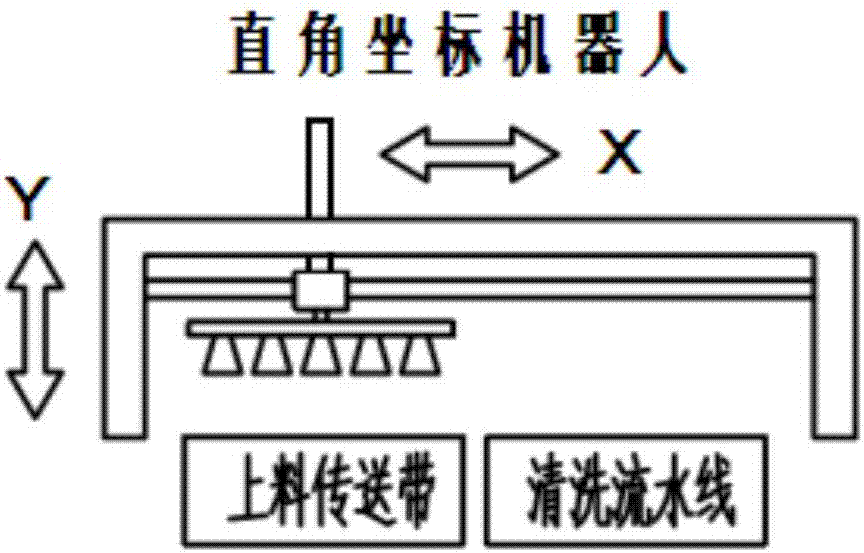

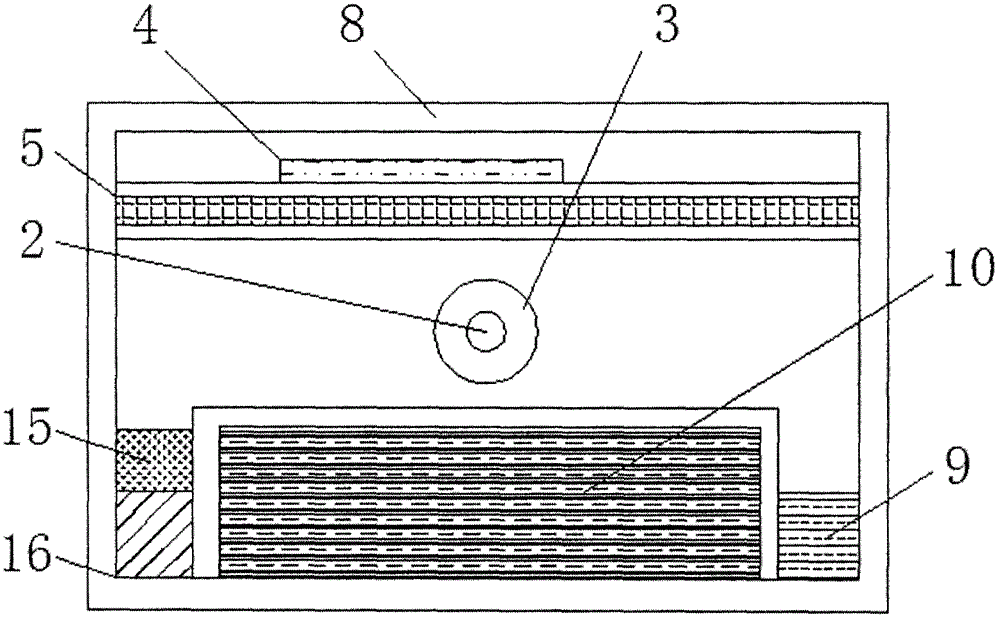

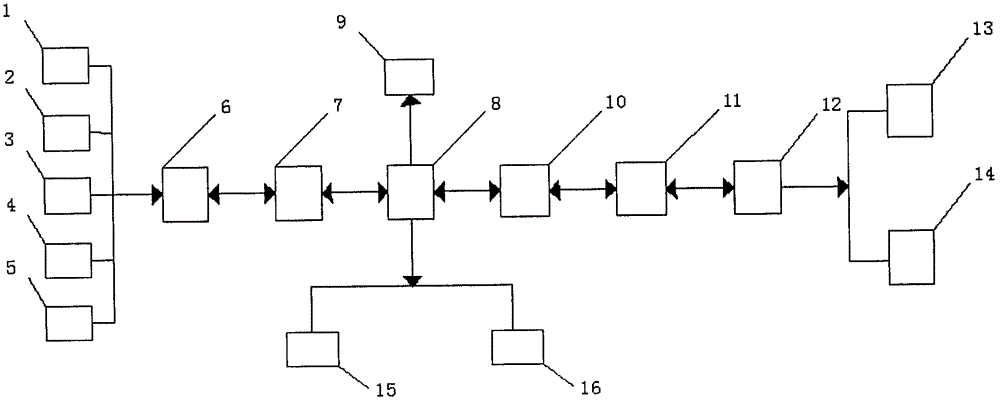

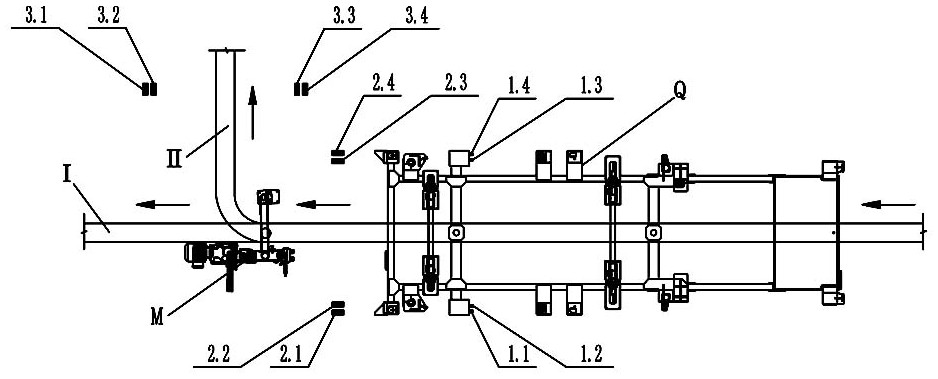

Poultry egg cleaning production line feed system and control method

ActiveCN106966162AMeet the beat requirementsReduce workloadConveyorsControl devices for conveyorsProduction lineEngineering

The invention relates to a poultry egg cleaning production line feed system and a control method. By adoption of the poultry egg cleaning production line feed system, poultry eggs in paper discs can be automatically adsorbed and moved to a cleaning production line; the empty discs of the adsorbed paper discs and the paper discs provided with the residual eggs are classified; the empty discs are directly transferred to a empty disc recovering unit; and the paper discs provided with the residual poultry eggs are transferred to a residual egg picking area to wait for manual residual egg picking; and the empty discs subjected to manual picking are transferred to the empty disc recovering unit. Compared with existing poultry egg cleaning and feeding mode, by adoption of the poultry egg cleaning production line feed system provided by the embodiment of the invention, firstly, no manual repeated poultry egg adsorbing action is needed, the workload of a worker can be decreased, meanwhile, missed adsorption caused by human errors is avoided, and the feeding takt time is shortened so that the feed system can meet the takt time requirement of a poultry egg cleaning system. The feed system can further separate the paper discs provided with the residual eggs, so that residual egg re-picking and re-adsorption are facilitated.

Owner:BEIJING UNIV OF TECH

Embedded reconfigurable robot control system with FPGA

InactiveCN105666496AScientific and reasonable structureStrong controlProgramme-controlled manipulatorRobotic systemsControl system

The invention discloses an embedded reconfigurable robot control system with an FPGA. The embedded reconfigurable robot control system with the FPGA comprises the controller FPGA, a wireless remote control receiver and an arm executing module. The wireless remote control receiver is embedded and installed in the bottom of the controller FPGA, an arm clamping detector and an arm lifting detector are installed on the left side of the wireless remote control receiver, and a lifting in-place signal detector is installed on the right side of the wireless remote control receiver. The controller FPGA is provided with an ultrasonic and photoelectric detector, a sound sensor is installed above the ultrasonic and photoelectric detector, a forwarding infrared detector and a retreating infrared detector are installed on the controller FPGA, an input module is installed at a corresponding position, inside the controller FPGA, of the retreating infrared detector, and the input module is provided with a walking value counting device. The embedded reconfigurable robot control system with the FPGA is higher in control intensity and more sensitive, the reconfigurable function on a robot system is achieved through the input module, detection is more comprehensive through all the detectors, and control is more convenient.

Owner:GUANGDONG IND TECHN COLLEGE

Robot handling fixture and handling system for engine cylinder head based on vision

ActiveCN105314394BHigh positioning accuracyImprove applicabilityConveyor partsCylinder headControl system

Owner:CHANGSHA CTR ROBOTICS

Device for simultaneously detecting straightness of two sides of frame for rectangular frame corner connector automated assembly machinery

ActiveCN108801197AFit tightlyEfficient and accurate detectionMeasurement devicesEngineeringConveyor belt

The invention relates to a device for simultaneously detecting the straightness of two sides of a frame for the rectangular frame corner connector automated assembly machinery, which is characterizedin that the device is composed of a V-shaped groove assembly, a sensor assembly and an air cylinder assembly, wherein the V-shaped groove assembly is composed of a V-shaped groove, V-shaped groove fixing plates, fixing bolts and fixing screws, the sensor assembly is composed of sensors, internal surface fixing nuts and external surface fixing nuts, and the air cylinder is mainly composed of a lefttransverse air cylinder, a right transverse air cylinder, air cylinder fixing plates, fixing bolts, fixing nuts, a longitudinal air cylinder, a fixing plate and fixing screws. The device has the characteristics of high precision, high efficiency and high reliability, can be directly installed on a rectangular frame assembly machine and used by being combined with a matched conveyor belt, and canrealize the unmanned operation of the whole detection process.

Owner:JIANGSU UNIV

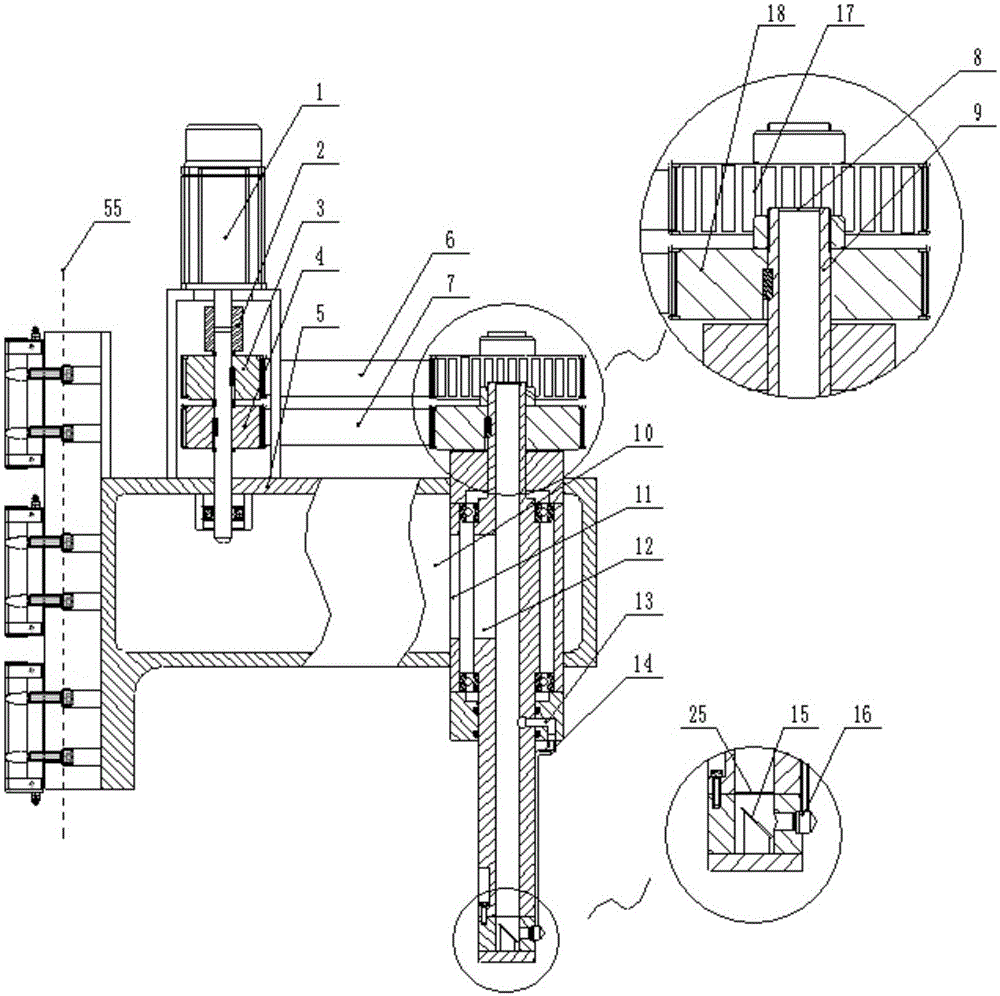

A Single Light Source Parallel Rotary Ventilation Laser Machining Spindle System

ActiveCN104475969BEnables parallel processingMeet the beat requirementsLaser beam welding apparatusLaser processingSystem stability

The invention discloses a single-light-source parallel rotating and ventilating laser processing spindle system which is applicable to the laser processing of surfaces of inner pores of porous parts. According to the technical scheme, the single-light-source parallel rotating and ventilating laser processing spindle system is that laser processing spindles are grouped, wherein transmission systems of the laser processing spindles in each group are arranged by layers; each laser processing spindle is driven to rotate through a motor; the energy of a laser source is divided and respectively introduced into each processing spindle through an external light path; auxiliary air is charged into each spindle and then is output together with laser by a coaxial manner. According to the single-light-source parallel rotating and ventilating laser processing spindle system, the laser output and the rotating of the spindles are under one source, so that the processing quality caused by the fluctuation of laser power and the mechanical vibration can be avoided being unstable; the beneficial effects achieved are that the processing efficiency is raised in multiples, the structure of the system is compact, and the stability of the system is improved; the system is particularly suitable for laser processing of surfaces of cylinder pores with small spacing of a multi-cylinder engine.

Owner:JIANGSU UNIV

Position returning block assembly machine for automobile combined switch

InactiveCN101477905BQuality improvementImprove efficiencyElectric switchesMetal working apparatusControl engineeringStructural engineering

The invention discloses an assembly machine for an automobile combined switch homing block, which comprises a bench; a slide block linearly sliding forward and backward is installed on the bench; a homing block fixture is installed on the slide block; a homing block accommodation groove is formed in the homing block fixture; a pressing mechanism is installed at the upper part the homing block fixture; the pressing mechanism consists of a lower air cylinder installed at the upper part the homing block fixture and a punch fixedly connected with the lower end of a piston rod of the lower air cylinder; a gas claw compressing mechanism and a spring feeding mechanism are respectively arranged on the left side and the right side of the homing block fixture; and the gas claw compressing mechanismcomprises two horizontal fixture blocks. The assembly machine realizes assembly automation, improves the quality and the efficiency of spring assembly on the automobile combined switch homing block, and satisfies operation requirements of the modern assembly detection line.

Owner:合肥安达数控技术有限责任公司

An automatic verification system and method for an electric energy meter

ActiveCN106125036BReduce feeding pressureReasonable utilizationElectrical measurementsProgrammable logic controllerEngineering

The invention provides an automatic verification system and method for an electric energy meter. The system comprises a PLC (Programmable Logic Controller), a delivery roller transport line controlled by the PLC and used for delivering turnover boxes out of a storage, a return roller transport line for returning the turnover boxes to the storage, a single-layer turnover box cache line for transporting the turnover boxes, a turnover box stacking cache line for caching the turnover boxes, an electric energy meter recheck belt line for transporting unqualified electric energy meters; a metering tray transport line for transporting a metering tray, a feeding robot and a discharging robot for moving electric energy meters or turnover boxes, and a turnover box monitoring sensor connected with the PLC and arranged on the single-layer turnover box cache line. By adopting the caching mode of combining a single-layer turnover box cache area with a multi-layer turnover box stacking area and intelligently transporting the turnover boxes via roller lines, the task executed by each robot at the same moment is balanced, the action path of a single robot is simplified, and the operating efficiency of the feeding and discharging robots is greatly improved.

Owner:STATE GRID CORP OF CHINA +1

A station tool for handling cylinder head test pieces

Owner:芜湖火龙动力科技有限公司

Robot handling fixture and handling system for engine block based on vision

ActiveCN105345585BHigh positioning accuracyImprove applicabilityMetal working apparatusTransfer systemControl system

The invention discloses a vision-based robot transfer clamp for engine cylinder blocks. The vision-based robot transfer clamp for the engine cylinder blocks comprises a clamp body which is connected with a transfer robot body. The clamp body is provided with a vision system, a detection system and a pneumatic control system. The vision system, the detection system and the pneumatic control system are all connected with a control system of a transfer robot. The invention further discloses a vision-based robot transfer system for the engine cylinder blocks. The vision-based robot transfer system for the engine cylinder blocks comprises the transfer robot, the robot control system, the vision system, the detection system and the pneumatic control system. The robot control system controls the transfer robot, the vision system, the detection system and the pneumatic control system. Through the robot transfer clamp and the robot control system, automation and intellectualization of cylinder block transfer can be achieved, the transfer efficiency is high, the production cost is low, the transfer safety is high, and the requirement for the takt of robot machining can be met.

Owner:CHANGSHA CTR ROBOTICS

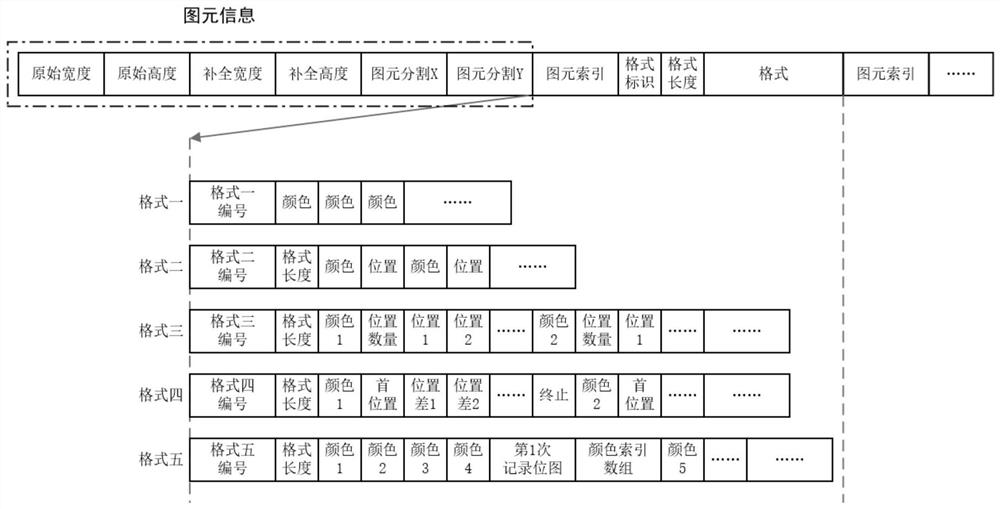

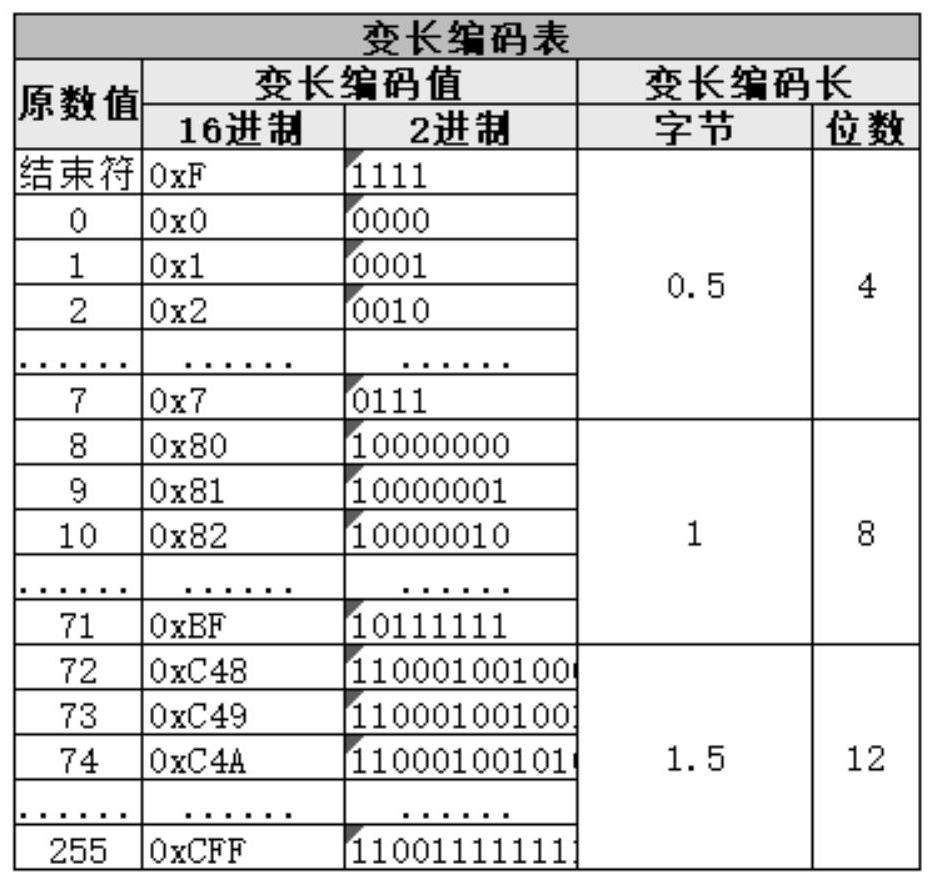

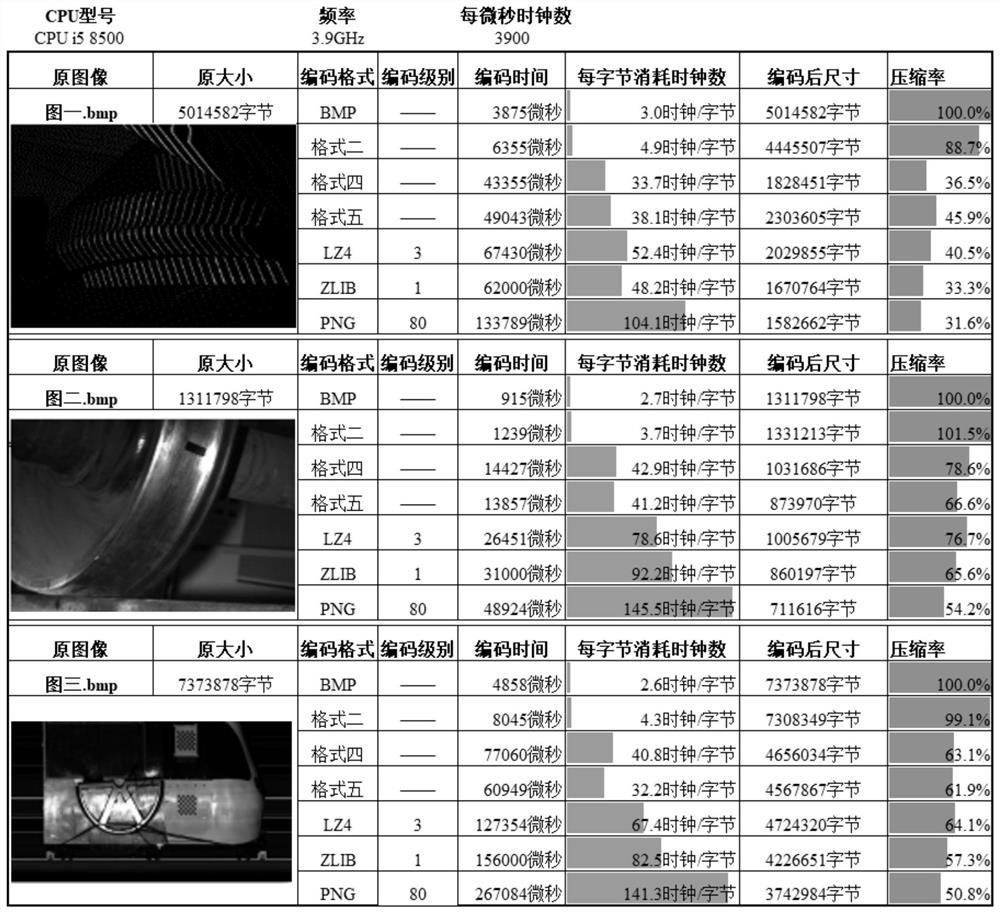

Picture compression method

PendingCN114332261AEasy to compressMeet the beat requirementsImage codingPattern recognitionComputer graphics (images)

The invention discloses a picture compression method, which comprises the following steps of: 1) determining a background color of a single picture, and dividing primitives; 2) screening pixels of which the pixels are all background colors, filtering, and recording the remaining pixels as to-be-coded pixels; 3) determining a basic color; replacing all basic colors in the primitives with K; determining coding format types for all non-K pixels in the to-be-coded primitives according to coding levels selected by a user, acquiring a format with the minimum storage length in each format in the same coding level, and performing compression storage on the primitives by using the format; when the format with the minimum storage length in each format in the same coding level is obtained, the storage lengths of the formats 1-4 are obtained through calculation, and the storage length of the format 5 is obtained based on a coding result. According to the image compression method, the image can be compressed to a certain degree in a short time, the beat requirement is met, and the transmission and storage pressure is reduced to a certain degree.

Owner:易思维(杭州)科技有限公司

Cavity automatic foaming visual positioning device and automatic foaming method

ActiveCN111823471BHigh positioning accuracyFree from color interferenceProcess equipmentProcess engineering

The invention discloses a cavity automatic foaming visual positioning device and an automatic foaming method, belonging to the technical field of foaming process equipment. Including: the U industrial robot is fixedly connected with the fixed bracket; the fixed cover is fixed on the fixed bracket, the fixed cover is provided with an installation cavity, and an opening is opened on one side of the fixed cover; the industrial camera is set in the installation cavity, and the industrial camera The lens faces the opening, and the industrial camera is connected to the industrial robot in communication; the reversible cover is movably connected to the end of the fixed cover provided with the opening, and the reversible cover can move to face the opening; the foaming device is fixedly connected to the fixed bracket. The cavity automatic foaming visual positioning device and the automatic foaming method provided by the present invention can realize the automatic foaming operation of the body cavity, improve the efficiency of the foaming operation of the body cavity, ensure the quality of foaming, and avoid the damage of the foaming operation to the health of enterprise employees. harm.

Owner:SHANGHAI FANUC ROBOTICS

A liquid crystal screen handling manipulator docking device

ActiveCN108508638BSimplify the movement mechanismSmall footprintProgramme-controlled manipulatorNon-linear opticsRobot handSimulation

The invention relates to a docking device for a manipulator for handling liquid crystal screens, which includes an upper surface detection component and a lower surface detection component. The detection assembly consists of a lower sliding telescopic arm, a lower fixed arm, a lower connecting plate and a lower surface detection platform; the invention simplifies the motion mechanism, reduces the floor space, saves the transfer manipulator, and solves the problem of inconsistent background color during detection. Change the suction cup of the detection manipulator into two vacuum adsorption detection platforms, which can meet the requirements of visual inspection. The most important thing is that the free-fall docking method realizes fast and smooth handover, saves time, and meets the beat requirements. Realizes fast and smooth handover, saves time, meets beat request.

Owner:TAIYUAN FENGHUA INFORMATION EQUIP

Automatic selection system for trolley running path

ActiveCN110937344BSimple structureEasy to installControl devices for conveyorsMechanical conveyorsControl systemControl engineering

The invention discloses an automatic selection system for trolley running paths, which includes a conveying PLC control system and a turnout selection device controlled by the conveying PLC control system, and also includes a path selection indicating part, which is located at the front end of the trolley, and is manually moved Adjust from the zero position to the target path indication position; a signal sending part, located on the ground around the initial path of the trolley, interacts with the path selection indication part to collect target path indication data, and the target path indication data is determined by the The signal sending part is transmitted to the conveying PLC control system; a reset mechanism is located on the ground around the target path of the trolley, and is used to restore the path selection indicator part from the target path indicator position to zero. The invention has a simple structure, is easy to install and use, and can conveniently and quickly transmit target path indication data to the conveying PLC control system, thereby achieving the purpose of automatic selection of trolley running paths and meeting the tempo requirements of a flexible production line for multi-model production.

Owner:郑州日产汽车有限公司

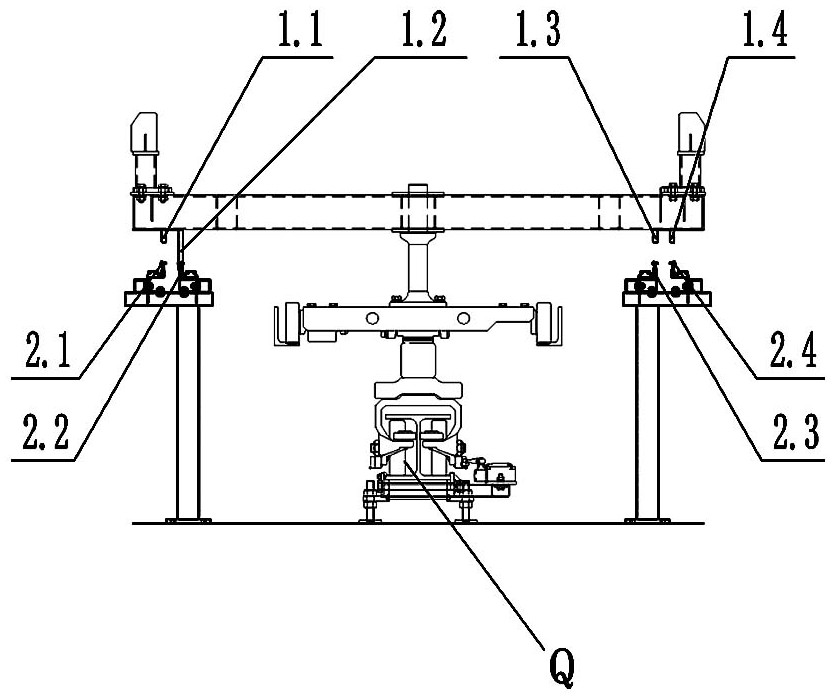

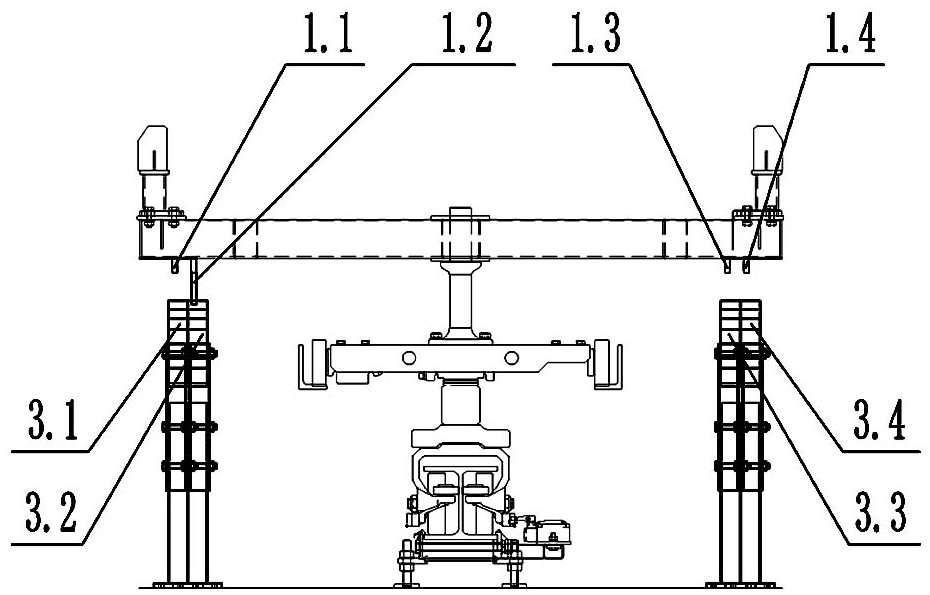

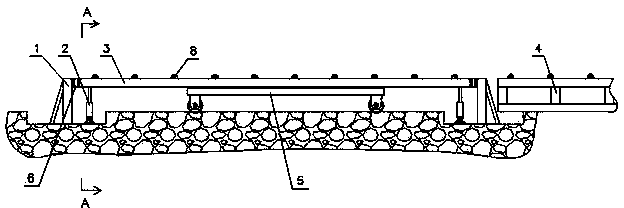

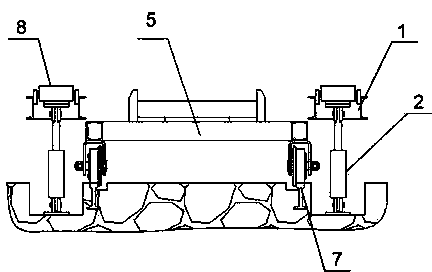

Lifting device for transferring floor on production lines

InactiveCN104129607AMeet the beat requirementsImprove production safetyRotary conveyorsProduction lineManufacturing technology

The invention discloses a lifting device for transferring a floor on production lines and relates to the technical field of manufacturing of automobile production line equipment. The lifting device comprises lifting racks arranged on two sides of a rail vehicle; two ends of each lifting rack are connected with guide supports through sliders, respectively; the sliders are slidablely connected with the guide supports; the guide supports are fixed on the ground; lifting cylinders are disposed below each lifting rack; extension ends of the lifting cylinders are connected with the lifting racks; one end of every lifting rack is adjacent to one end of a floor welding platform. Compared with the prior art, the lifting device is simple in structure and convenient to operate; high occupation rate of a crane in the production process can be avoided; meanwhile, the requirement for the production line Takt time can be met, and work efficiency can be effectively improved.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

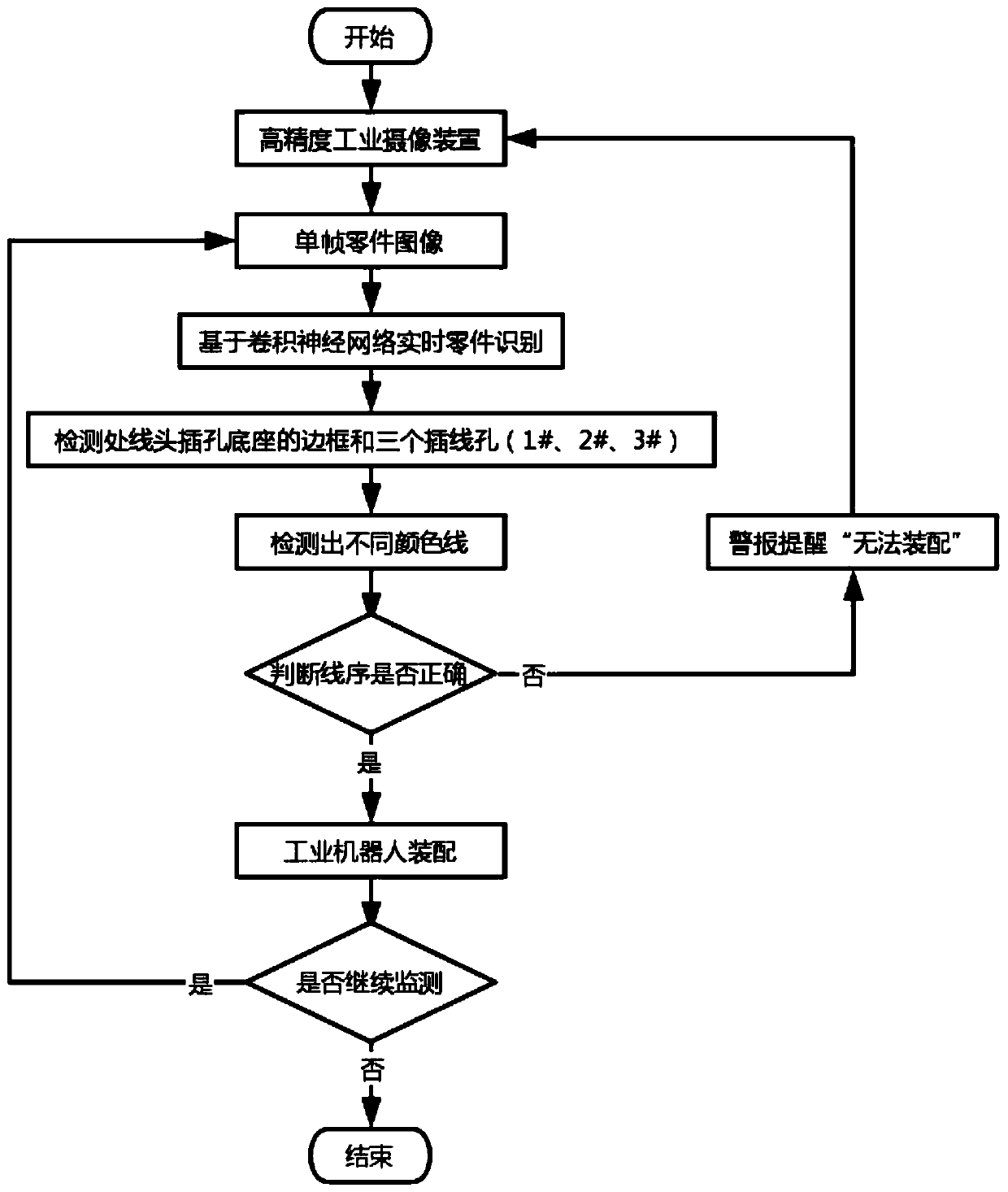

Charging pile component line sequence color mistake-proofing detection method

PendingCN111383223ASolve the problem of slow productionHigh precisionImage enhancementImage analysisData setAlgorithm

The invention relates to a charging pile component line sequence color mistake-proofing detection method. The method comprises the following steps: 1, collecting a line sequence and color video sampleof a charging pile component; 2, acquiring a single-frame image of the video sample of the line sequence and the color of the charging pile component acquired in the step 1 to form a basic data set;3, generating a trained convolutional neural network detection model of the line sequence and the color of the charging pile component; and 4, obtaining an improved convolutional neural network detection model of the line sequence and the color of the charging pile component, and inputting the test set into the improved convolutional neural network detection model of the line sequence and the color of the charging pile component for testing to obtain a detection result. The charging pile component detection and classification precision and speed can be effectively improved, and the beat requirement of a production system is met.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

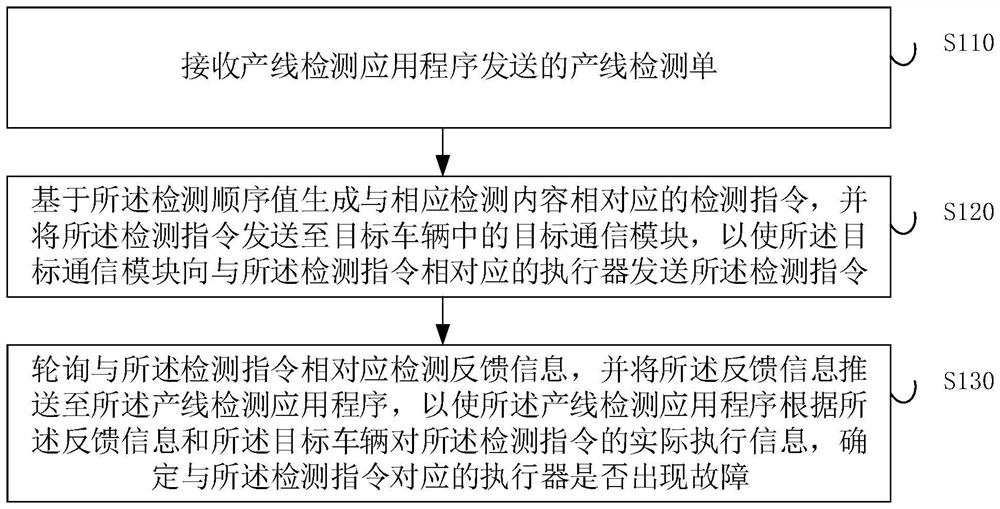

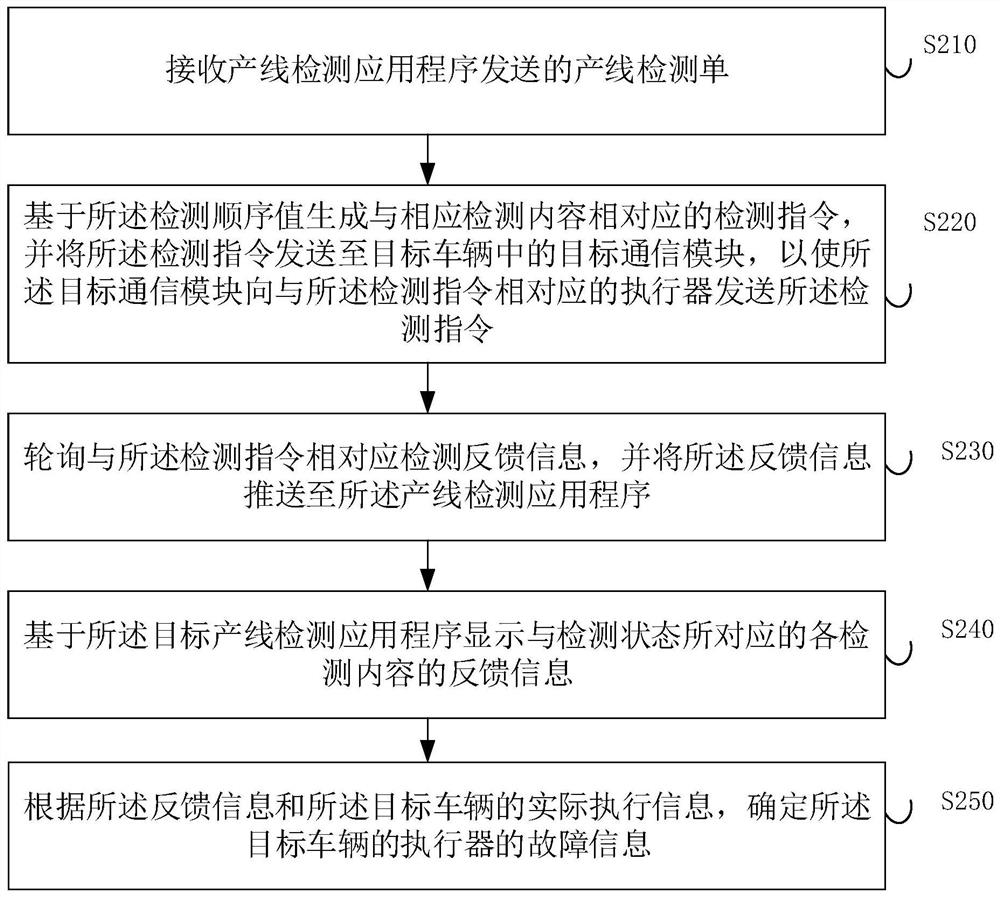

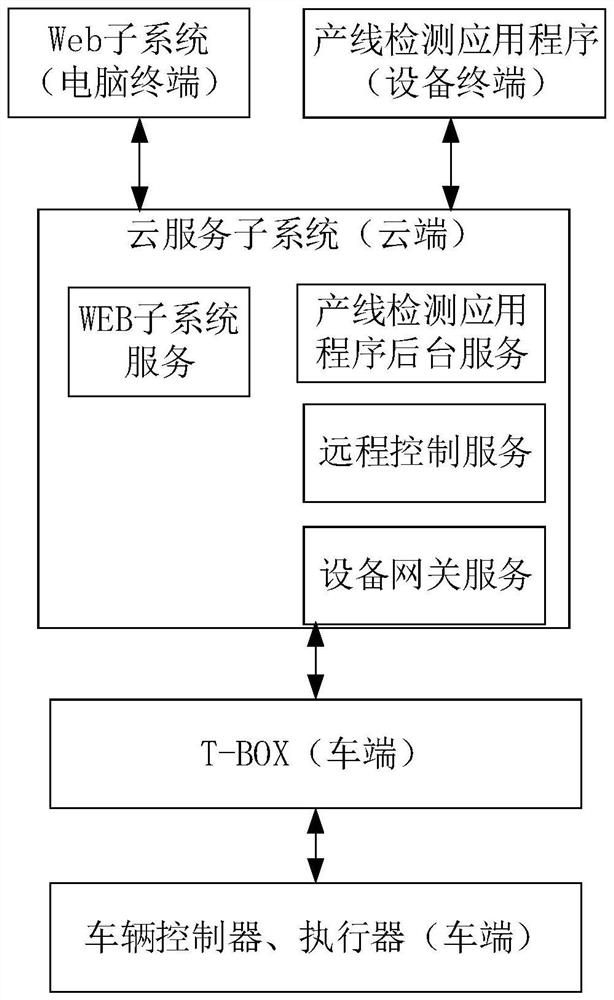

Remote control function detection method and device, electronic equipment and storage medium

PendingCN114460924AMeet the production line status requirementsSolve efficiency problemsProgramme controlElectric testing/monitoringEmbedded systemControl function

The embodiment of the invention discloses a remote control function detection method and device, electronic equipment and a storage medium. The method comprises the following steps: receiving a production line detection list sent by a production line detection application program; generating a detection instruction corresponding to the corresponding detection content based on the detection sequence value, and sending the detection instruction to a target communication module in the target vehicle; and detecting feedback information corresponding to the detection instruction in a polling manner, pushing the feedback information to a production line detection application program, and determining whether an actuator corresponding to the detection instruction has a fault or not. The problem that in the prior art, the whole remote control function production line cannot be effectively detected, so that the remote control function detection efficiency is low and is inaccurate is solved, the detection item of the vehicle type to which the vehicle belongs is detected based on the production line detection state, and the technical effect of improving the detection convenience and effectiveness is achieved.

Owner:CHINA FIRST AUTOMOBILE

Eight-connecting-rod press transmission mechanism

ActiveCN112959711AMeet the beat requirementsAmple loading and unloading timePress ramStructural engineeringControl theory

The invention provides an eight-connecting-rod press transmission mechanism which comprises a double-eccentric body, a triangular connecting rod, a connecting rod A, a V-shaped angle rod, a connecting rod B, a connecting rod C, and a guide column. An eccentric shaft A and an eccentric shaft B are arranged on the two axial sides of the double-eccentric body respectively. The triangular connecting rod is provided with three hinge points which are distributed in a triangular shape, namely a hinge point A, a hinge point B and a hinge point C; the hinge point A is hinged to the eccentric shaft A; one end of the connecting rod A is hinged with the eccentric shaft B; one end of the V-shaped angle rod is hinged with the other end of the connecting rod A; one end of the connecting rod B is hinged with the hinge point B, and the other end is hinged with the other end of the V-shaped angle rod; one end of the connecting rod C is hinged with the hinge point C; and the input end of the guide column is hinged with the other end of the connecting rod C. When the eight-connecting-rod press transmission mechanism is close to a bottom dead center, the sliding block speed is low, the quick-return characteristic is good during return stroke, the formability of parts is facilitated, more sufficient feeding and discharging time can be provided for a robot, and a motion curve can meet the beat requirement of a high-speed press line continuous production mode.

Owner:DALIAN DESIGN INST CO LTD CHINA FIRST HEAVY IND +1

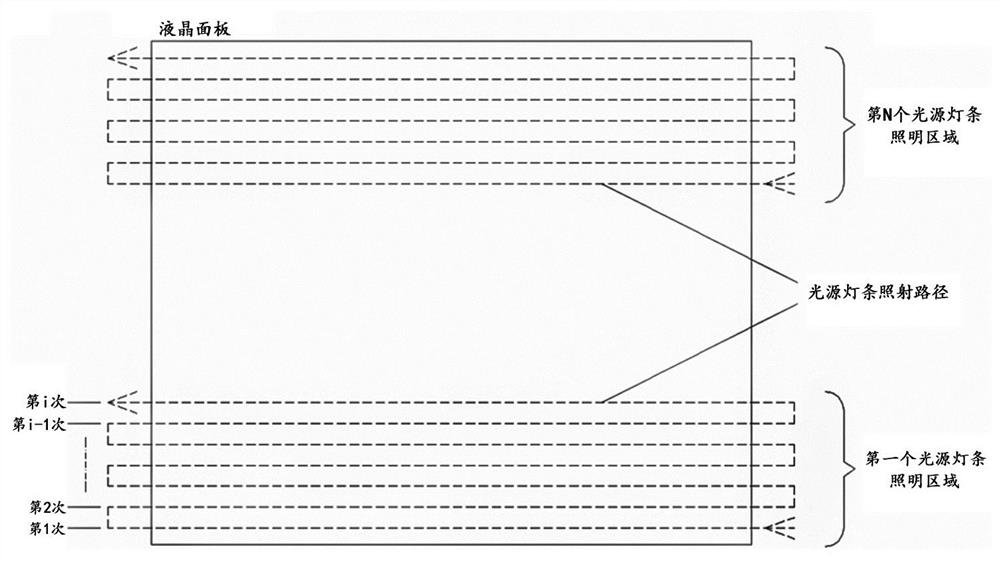

Device and method for controlling brightness divisions of exposure light sources for liquid crystal panels

ActiveCN113835250BIntensity controllableAddressing Imaging NeedsNon-linear opticsControl cellEngineering

The invention discloses a device and a method for controlling brightness divisions of a liquid crystal panel exposure light source. The device includes: a light source light bar controller, at least one lamp bead control unit and an industrial computer connected to the light source light bar controller; , each lamp bead control unit includes a DA conversion circuit and at least one lamp bead arranged in a line, each lamp bead is connected to the output end of the DA conversion circuit, and the input end of the DA conversion circuit is connected to the light source light bar controller I / O ports. The advantages of the present invention are: (1) The array area and the peripheral area can be detected at the same time, and only one defect detection scan is required, which can meet the equipment beat requirement and save the beat time. (2) The light source illumination of small areas can be controlled independently, and the peripheral area and the array area can be sub-area and multi-light intensity illumination. The light source intensity can be controlled independently, and the imaging needs of each area of the liquid crystal panel can be solved.

Owner:ZHAOQING ZHONGDAO OPTOELECTRONICS EQUIP CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com