An automatic verification system and method for an electric energy meter

An automatic verification and electric energy meter technology, applied in the measurement of electrical variables, measuring devices, instruments, etc., can solve the problems affecting the operation efficiency of the automatic verification line of electric energy meters, difficult to ensure the matching of operation rhythms, and restricting the efficiency of loading and unloading units. Reasonable utilization, sufficient and reasonable cache space, and shortened cycle cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the present invention.

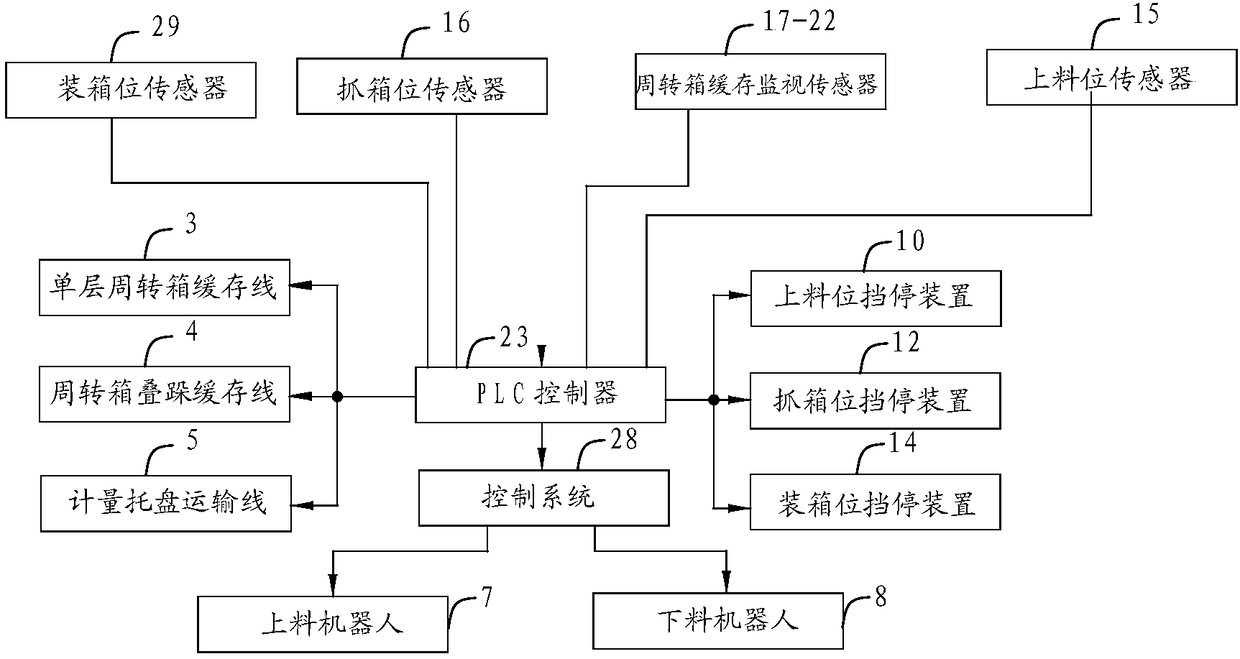

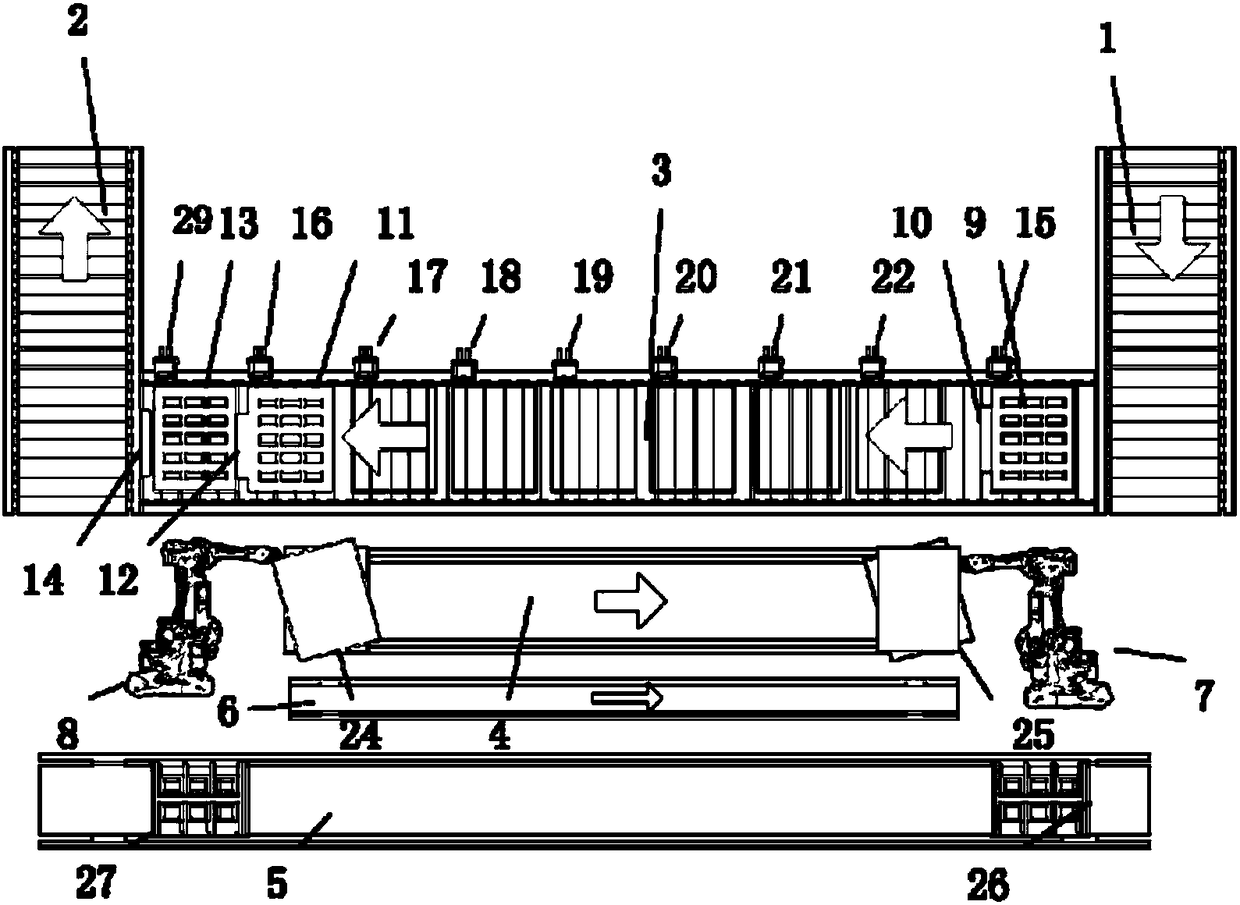

[0036] Please refer to figure 1 and figure 2 , the present invention provides an automatic verification system for electric energy meters, including a PLC controller 23, a delivery roller transport line 1 for the turnover box out of the warehouse, a return roller transportation line 2 for the turnover box back to the warehouse, and a Single-layer turnover box buffer line for transporting turnover boxes 3, Turnover box stacking buffer line for buffering turnover boxes 4, Electric energy meter re-inspection belt line for transporting unqualified electric energy meters 6, Metering tray for transporting metering trays The transportation line 5, the turnover box monitoring sensor installed on the single-layer turnover box buffer line 3 for sensing the position of the turnover box, the stop device for posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com