Apparatus for processing plastic material

A technology for plastic materials and waste plastics, applied in the fields of plastic recycling, transportation and packaging, recycling technology, etc., can solve the problems of narrowing of the cross section of the entry hole, poor entry characteristics, loss of throughput, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

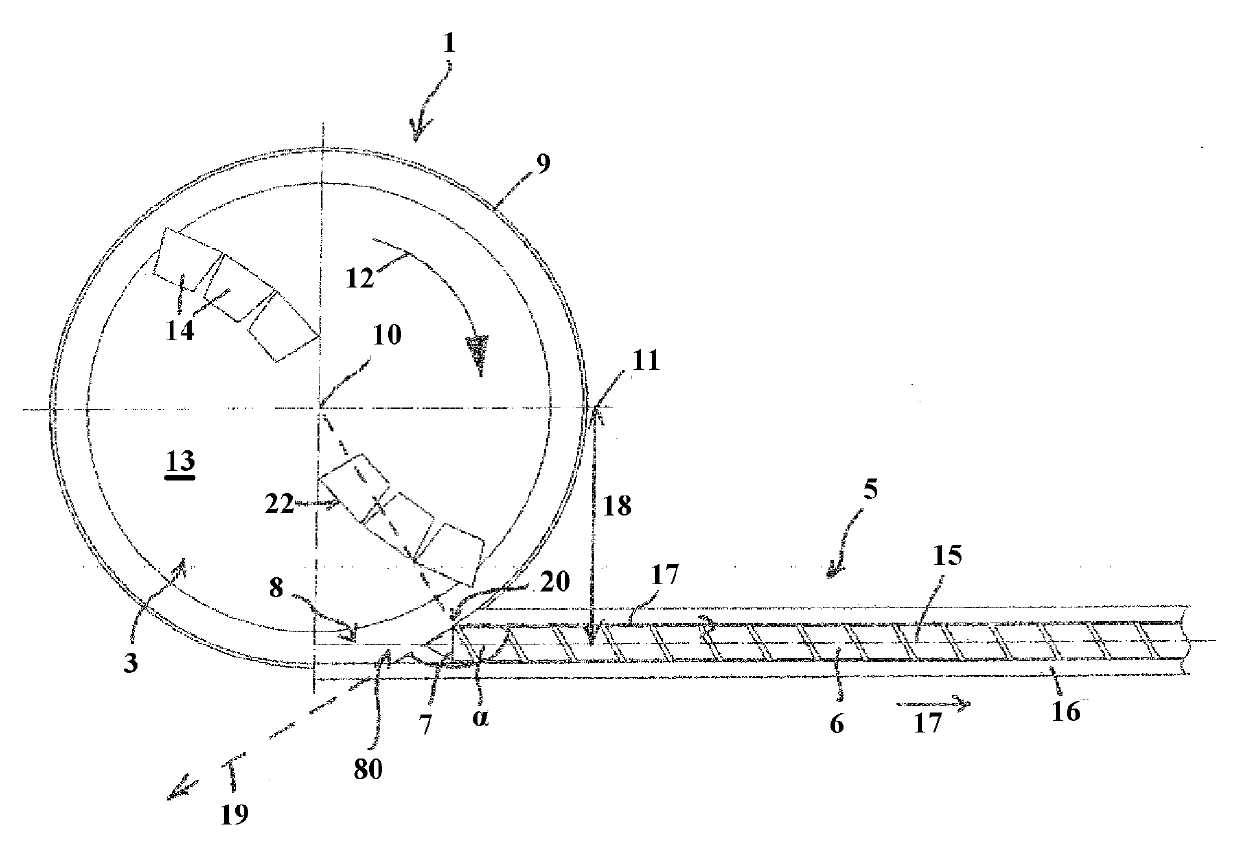

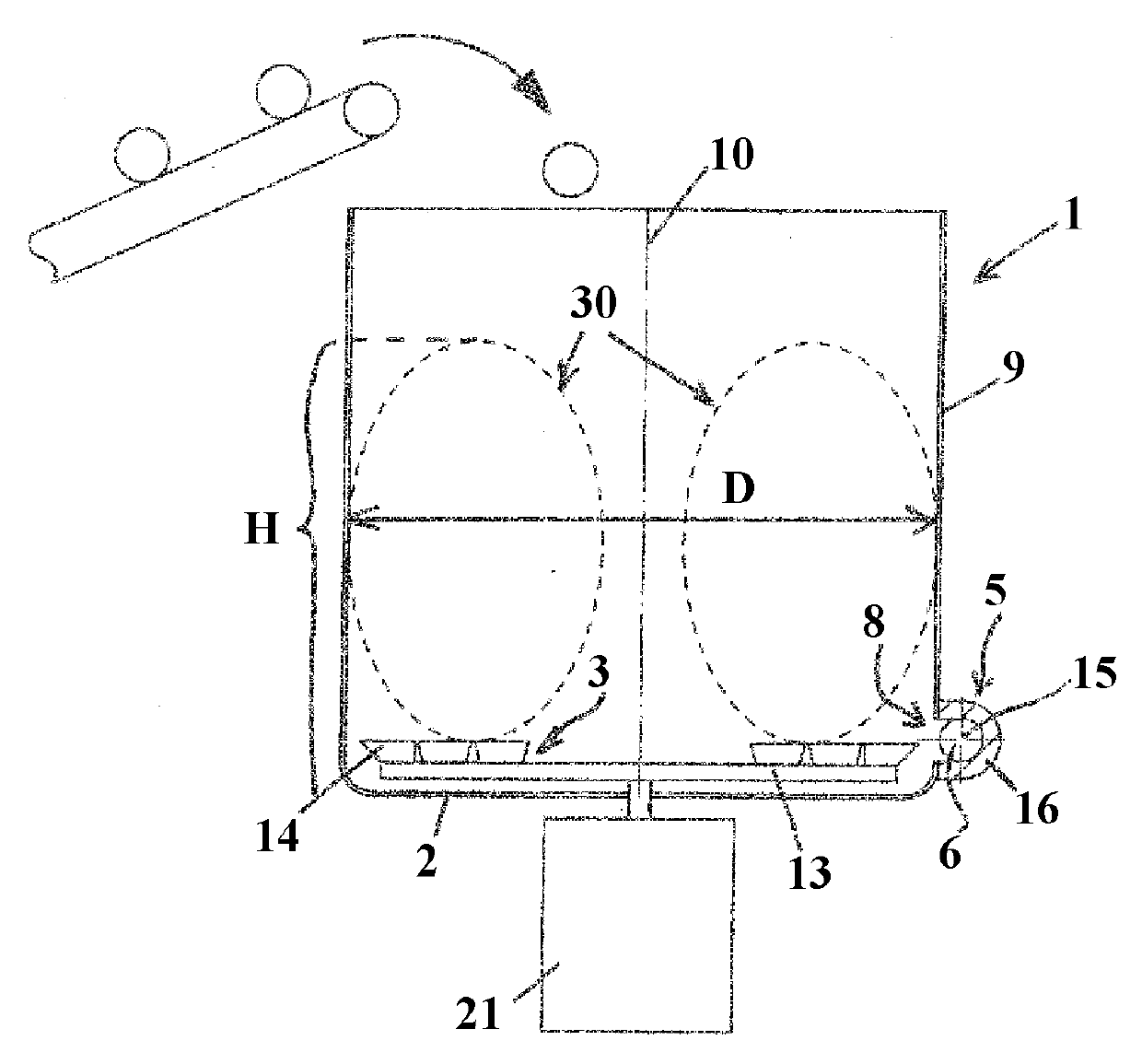

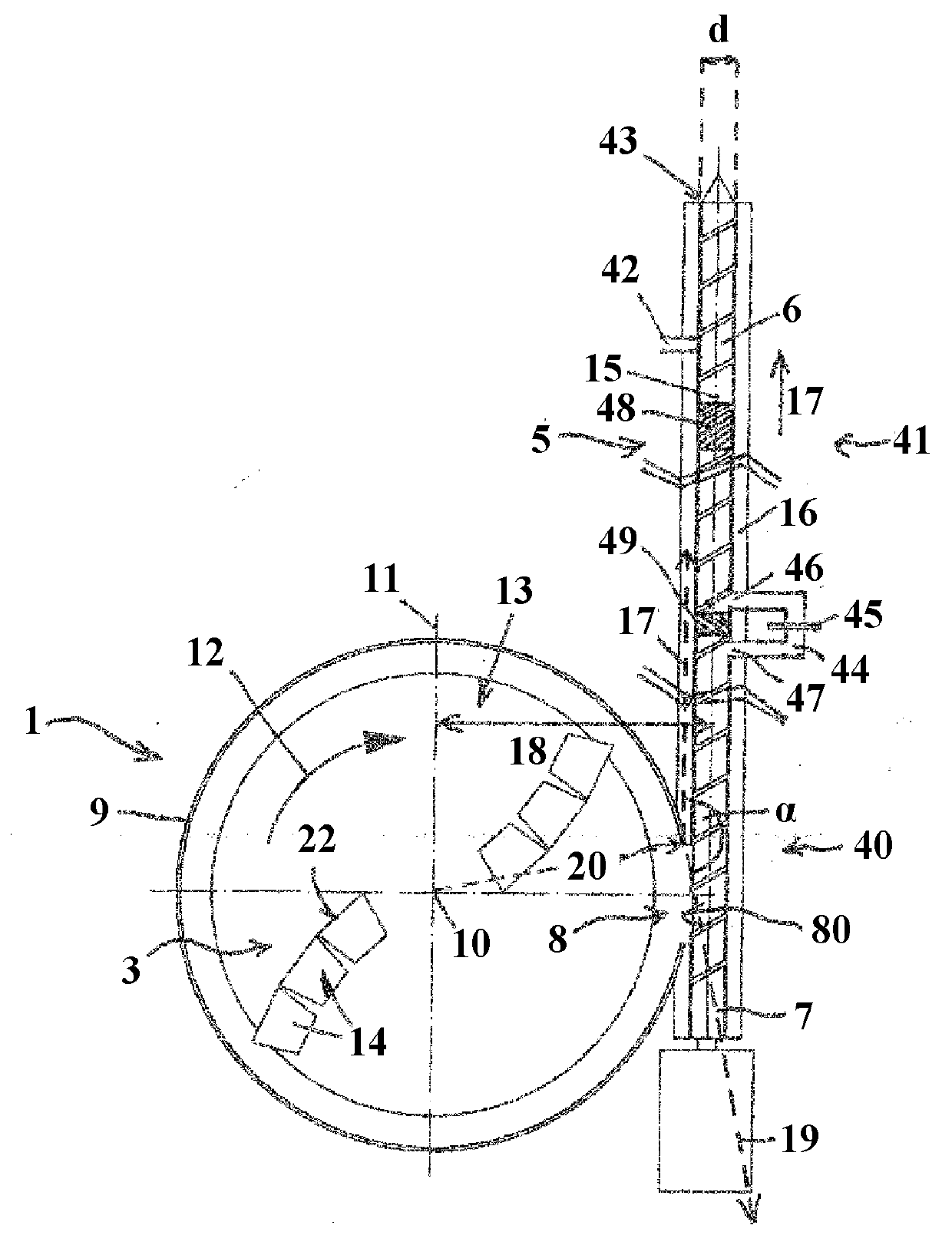

[0058] exist figure 1 and figure 2 The advantageous shredding compressor-extruder-combination for preparing or recycling plastic material shown in has a cylindrical container or shredding compressor or shredder 1 with a flat horizontal The bottom surface 2 and the vertical cylindrical covering-shaped side walls 9 oriented standardly thereto.

[0059] At a slight distance from the base 2, up to about 10 to 20% of the height of the side walls 9 - measured from the base 2 to the uppermost edge of the side walls 9 - and possibly less are arranged parallel to the base 2 Oriented flat carrier plate or tool holder 13 , which can be rotated in the direction of rotation or movement marked with arrow 12 about a central rotational axis 10 , which is at the same time the central central axis of container 1 . The carrier plate 13 is driven by a motor 21 located below the container 1 . Arranged on the upper side of the carrier plate 13 are knives or tools 14 , for example cutting knives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com