Apparatus for processing plastic material

A technology for synthesizing materials and waste materials, applied to mixers with rotating stirring devices, mixers, plastic recycling, etc., can solve problems such as poor feeding behavior, damaged passing rate, melting, etc., to reduce charging pressure, The effect of reducing the risk of filling up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

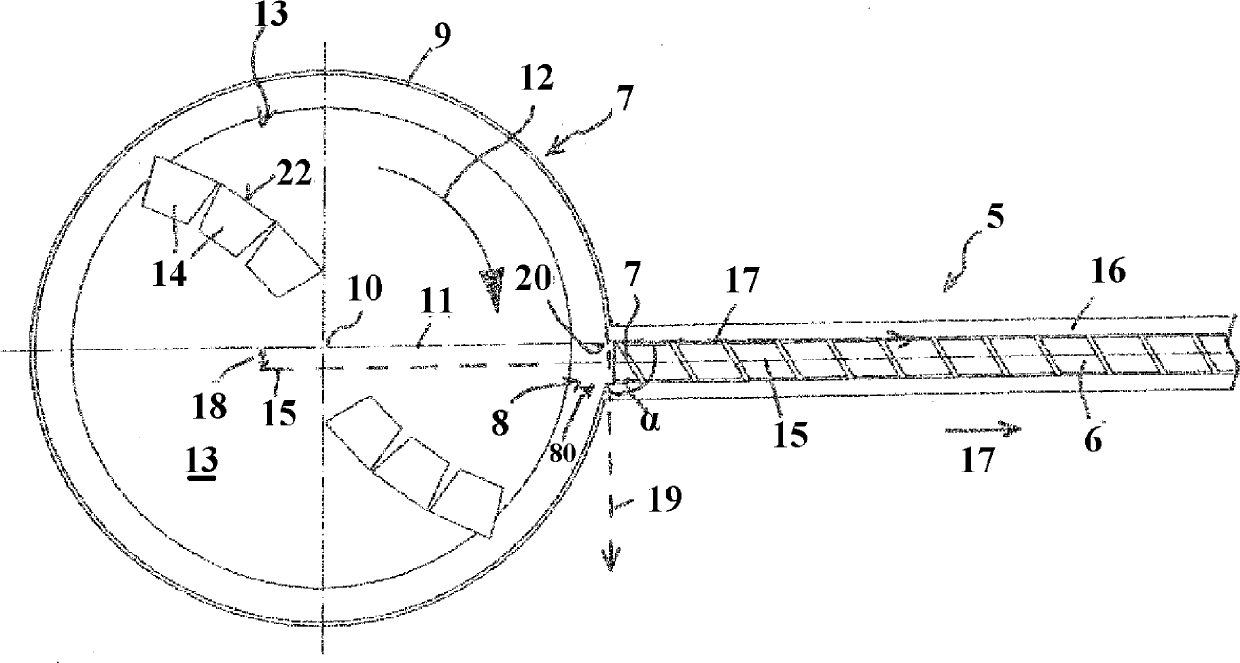

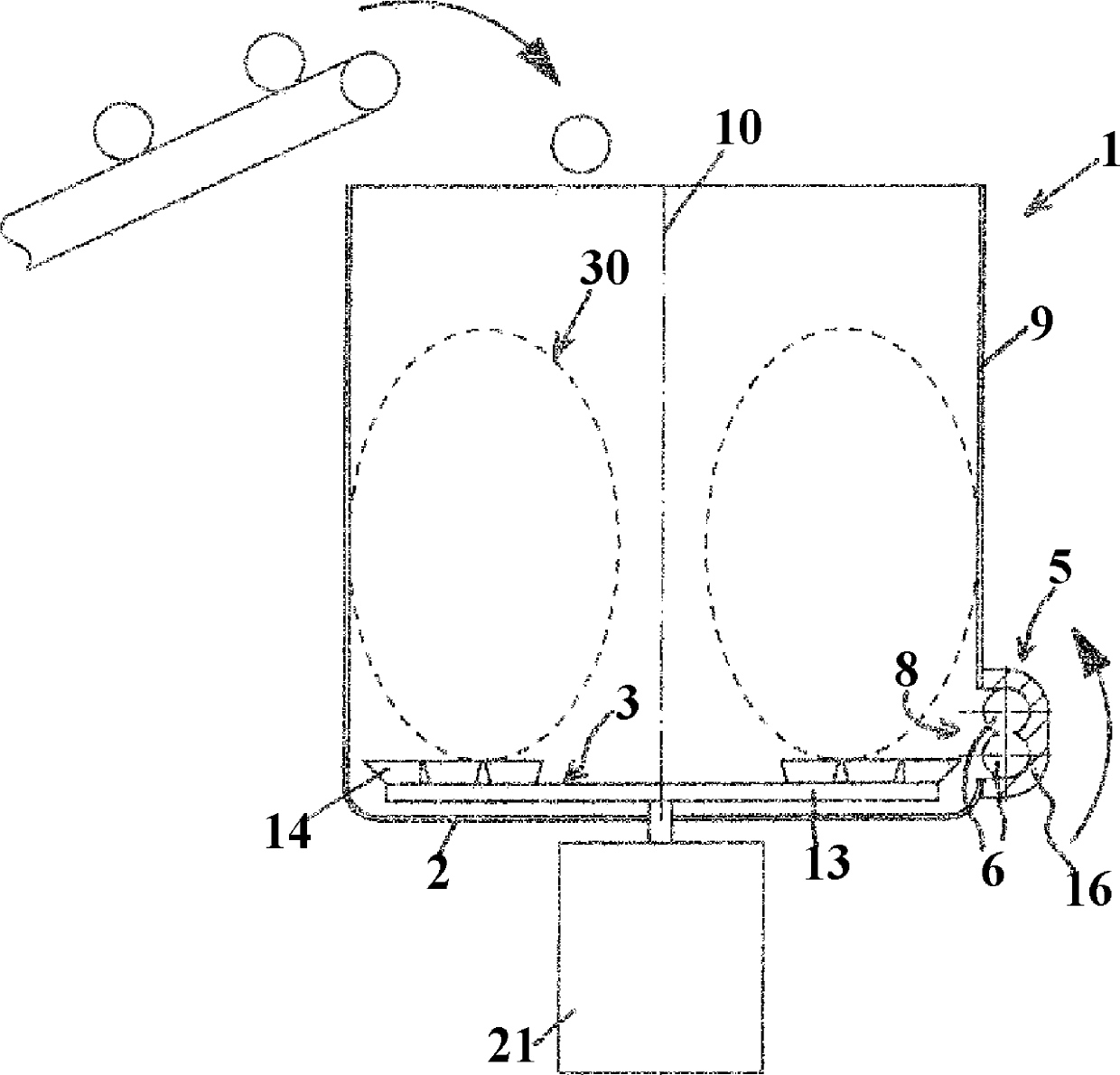

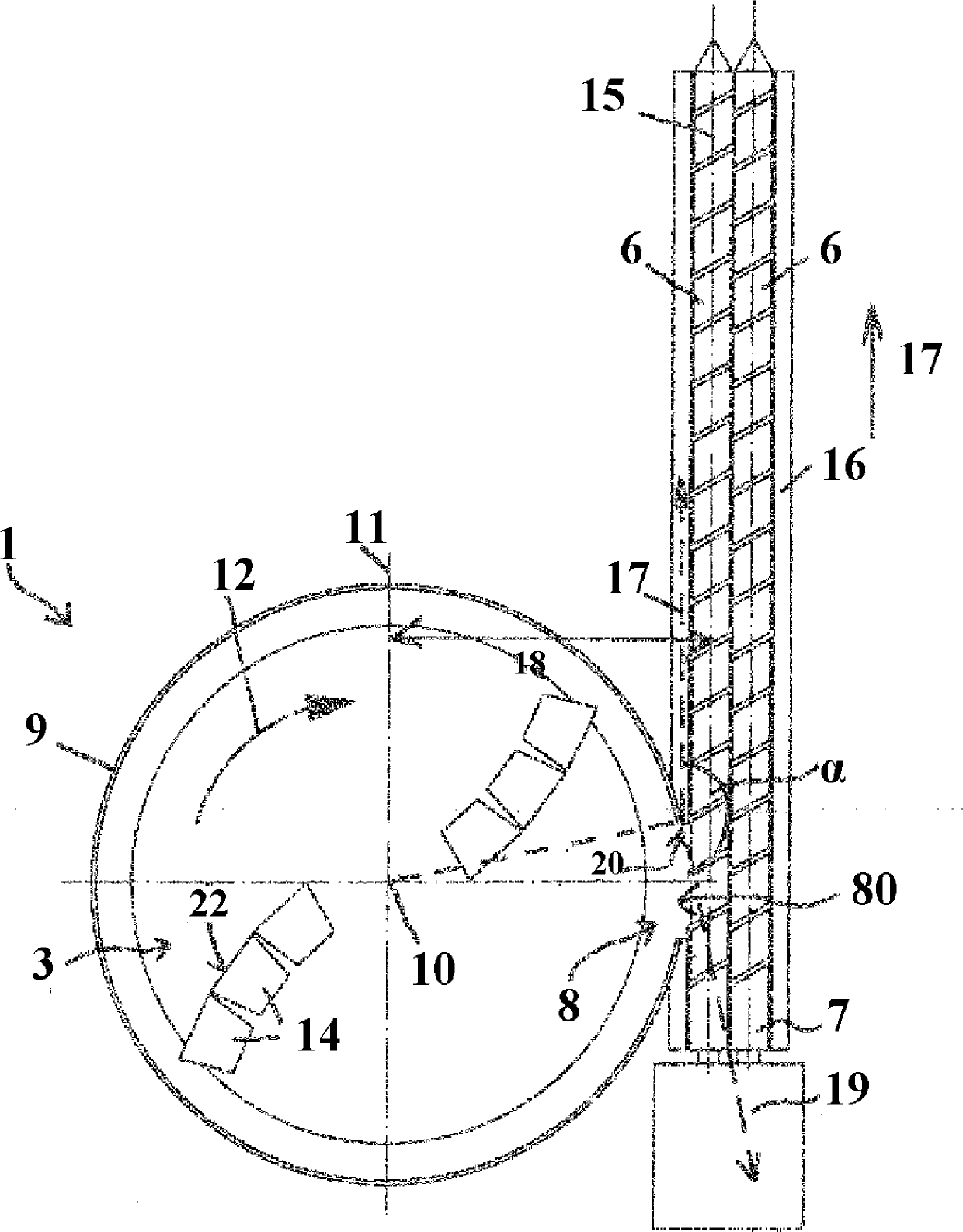

[0069] In the figures, neither the container nor the auger or the mixing tool is shown to scale, nor are they in proportion to each other. For example, in reality the container is often larger than shown here, or the screw is longer than shown here.

[0070] exist figure 1 with figure 2 The cutting-compressor-extruder-combinations shown from different positions in , are very similar in their structure and are therefore jointly described below. They are firstly distinguished by the arrangement of the screws 6 relative to each other, which will be explained in more detail later.

[0071] exist figure 1 with figure 2 The advantageous cutting compressor-extruder-combination for the production or recovery of synthetic materials shown in has a cylindrical container or cutting compressor or shredder 1 with a flat, horizontal bottom surface 2 and a vertical cylindrical enclosure-shaped side wall 9 oriented normal thereto.

[0072] In the case of a small distance from the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com