A mineral wool board waterline forming system

A mineral wool board and waterline technology, which is applied in the direction of ceramic forming machines, forming conveyors, auxiliary forming equipment, etc., can solve the problems of inability to ensure uniform transmission of slurry, high water content of mineral wool boards, and affecting the quality of mineral wool boards. , to achieve the effect of improving uniform cloth distribution, uniform mineral wool board slurry, and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0041] The present invention will be described in detail below with reference to the accompanying drawings and examples.

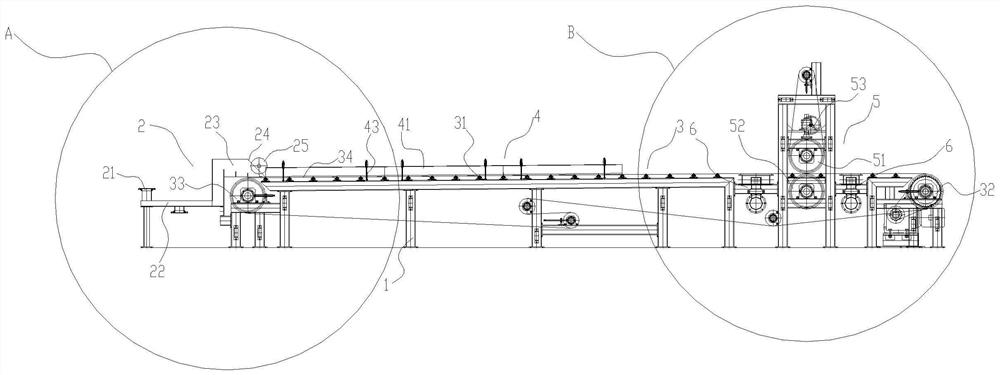

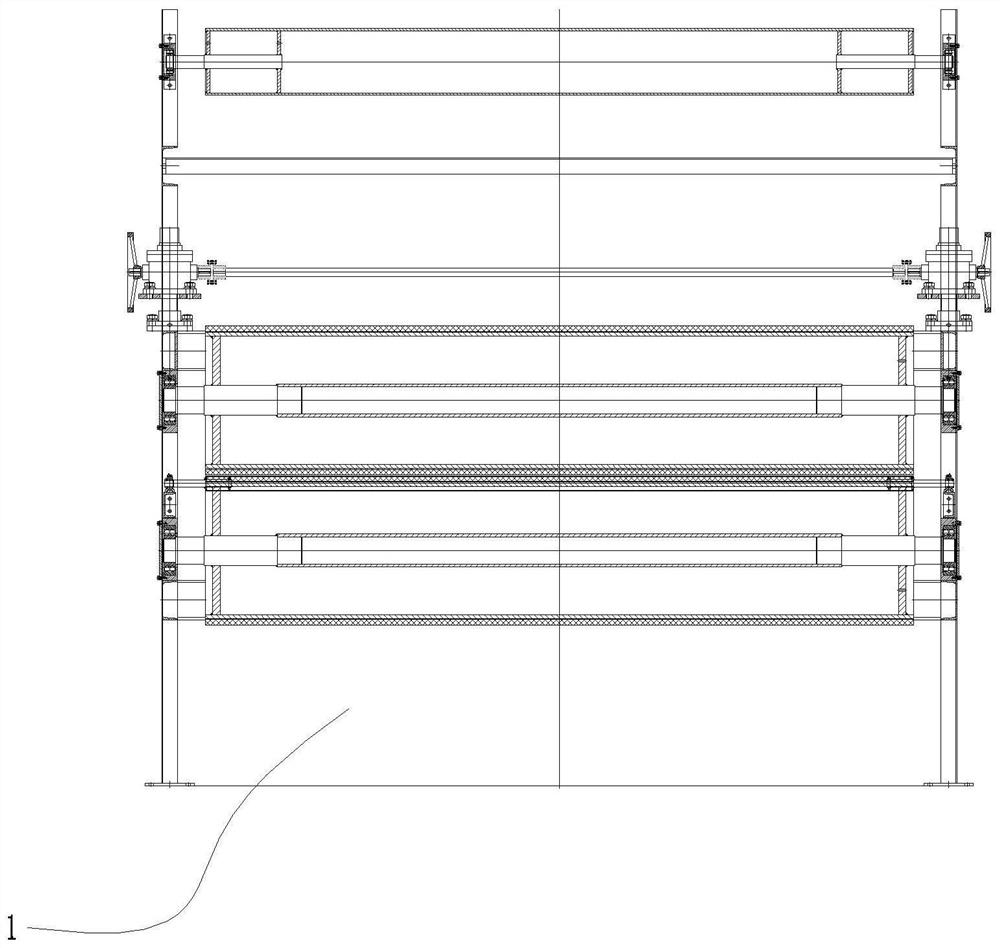

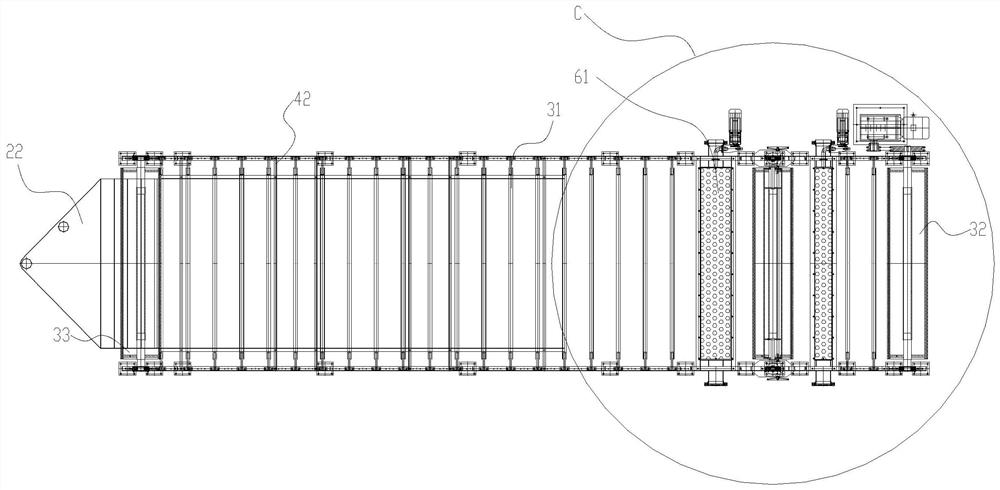

[0042] This embodiment relates to a mineral wool board waterline forming system, consisting of Figure 1 to Figure 6 As shown in , its overall structure includes a frame 1, a feeding device 2, a transmission device 3, a width forming device 4, a thickness forming device 5 and a vacuum dehydration device 6 to realize automatic and high-quality forming of mineral wool boards.

[0043] In this embodiment, the frame 1 is a split structure, and a thickness forming device 5 and a vacuum dehydration device 6 are arranged between the split frame 1. The feeding device 2 includes a feeding port 21, and one end communicates with the feeding port 21, The other end is located at the material guide p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com