Automatic selection system for trolley running path

A technology of operating path and selection system, which is applied in the direction of transportation and packaging, mechanical conveyors, conveyor objects, etc., can solve problems such as not being able to meet the normal production rhythm, changing the operating path of the trolley, and affecting the production efficiency of the line body, etc., to achieve The structure is simple, meets the beat requirements, and is easy to install and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

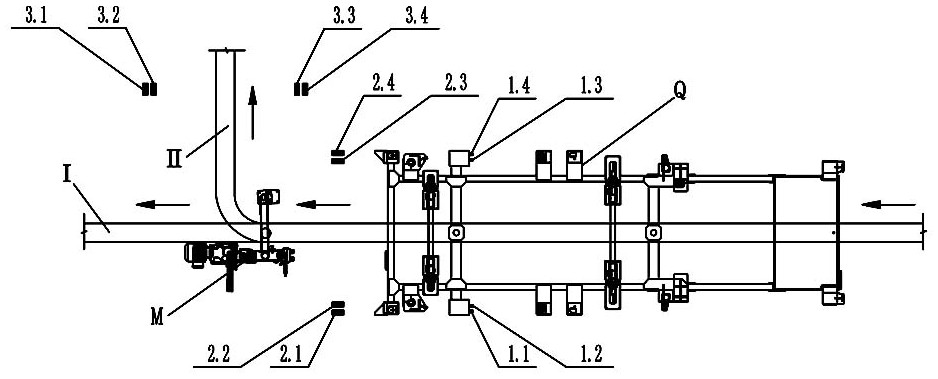

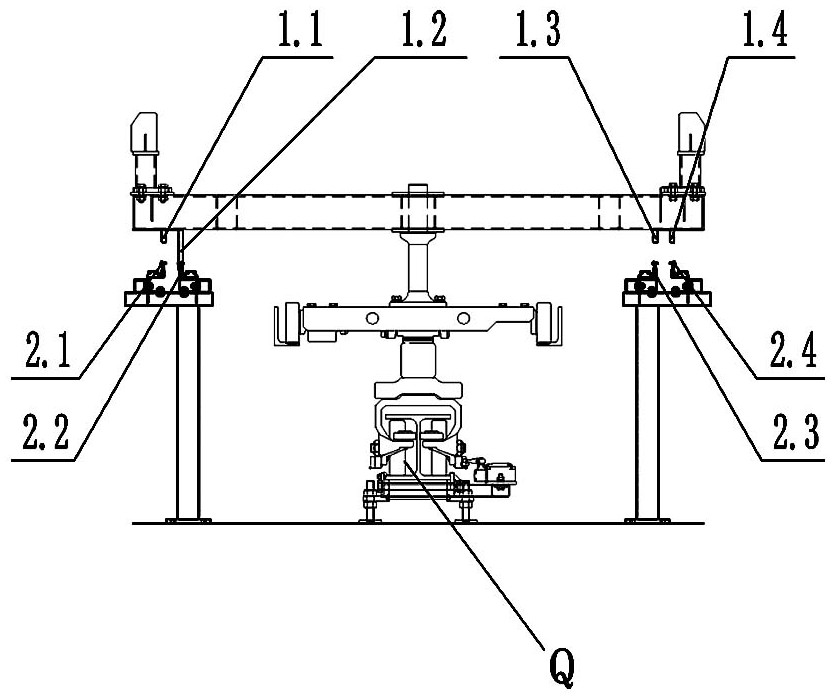

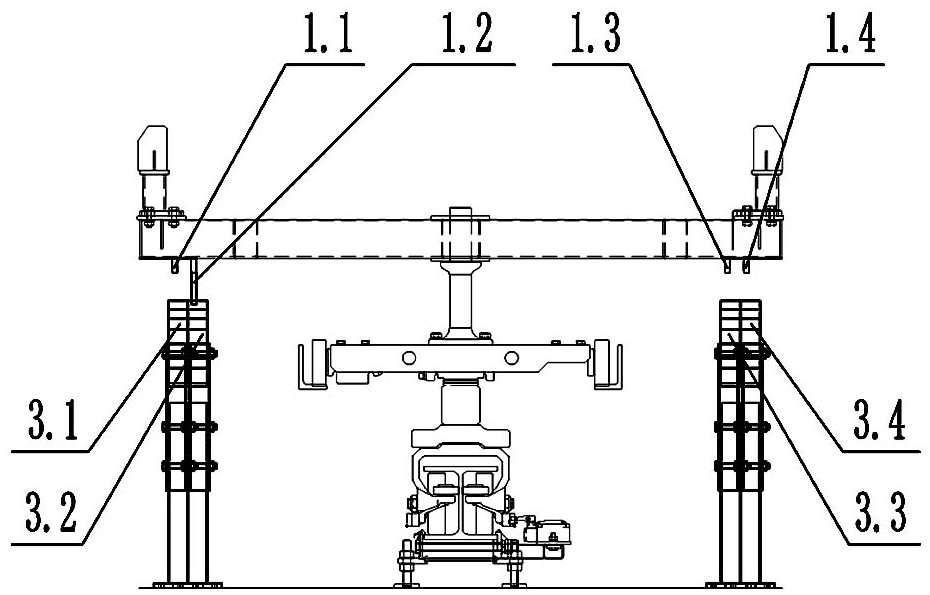

[0030] The trolley running path automatic selection system of the present invention includes a conveying PLC control system and a switch selection device controlled by it, and also includes:

[0031] A path selection indicator, located at the front end of the trolley, manually adjusted from zero to the target path indicator;

[0032] A signal sending part, located on the ground around the initial path of the trolley, collects target path indicating data by interacting with the path selection indicating part, and the target path indicating data is transmitted to the conveying PLC by the signal sending part Control System;

[0033] A reset mechanism, located on the ground around the target path of the trolley, is used to restore the path selection indicating part from the target path indication position to the zero position.

[0034] Attached below Figure 1-9 Embodiments of the present invention will be described in detail.

[0035] Such as figure 1 As shown, the trolley ru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com