Robot handling fixture and handling system for engine cylinder head based on vision

An engine cylinder head and vision system technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of inability to meet robot machining cycle requirements, low handling efficiency, high production costs, etc., to achieve automation and intelligence, handling High efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims.

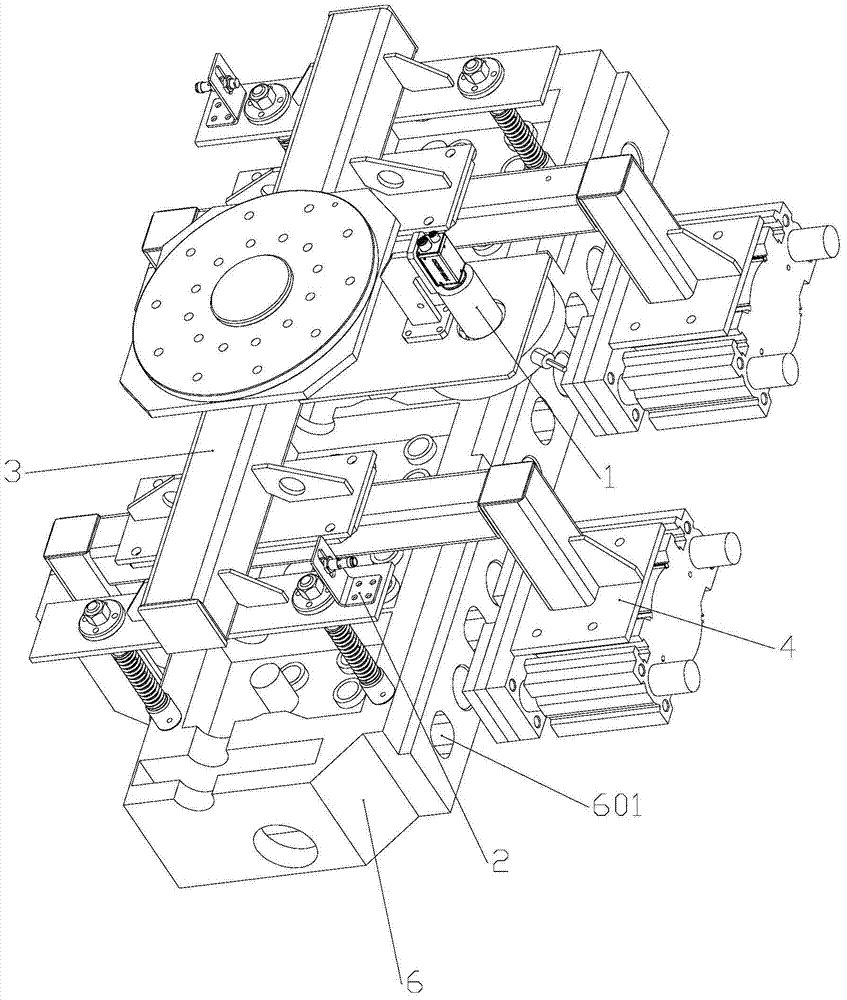

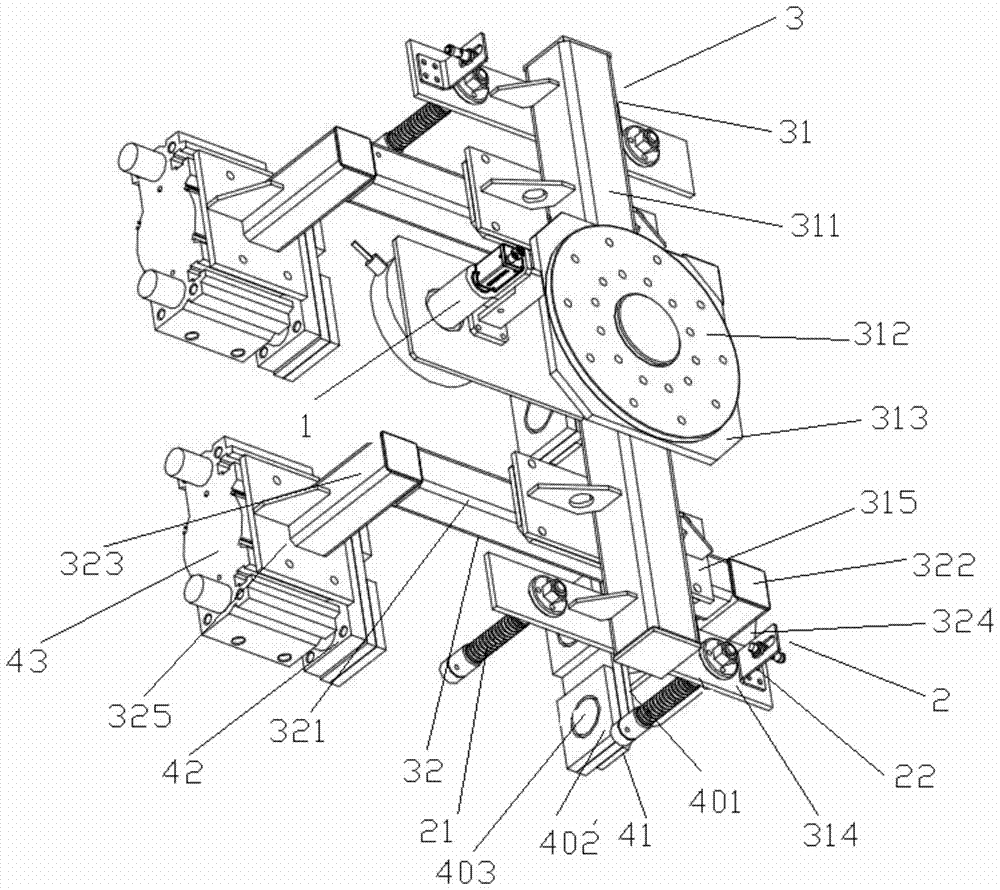

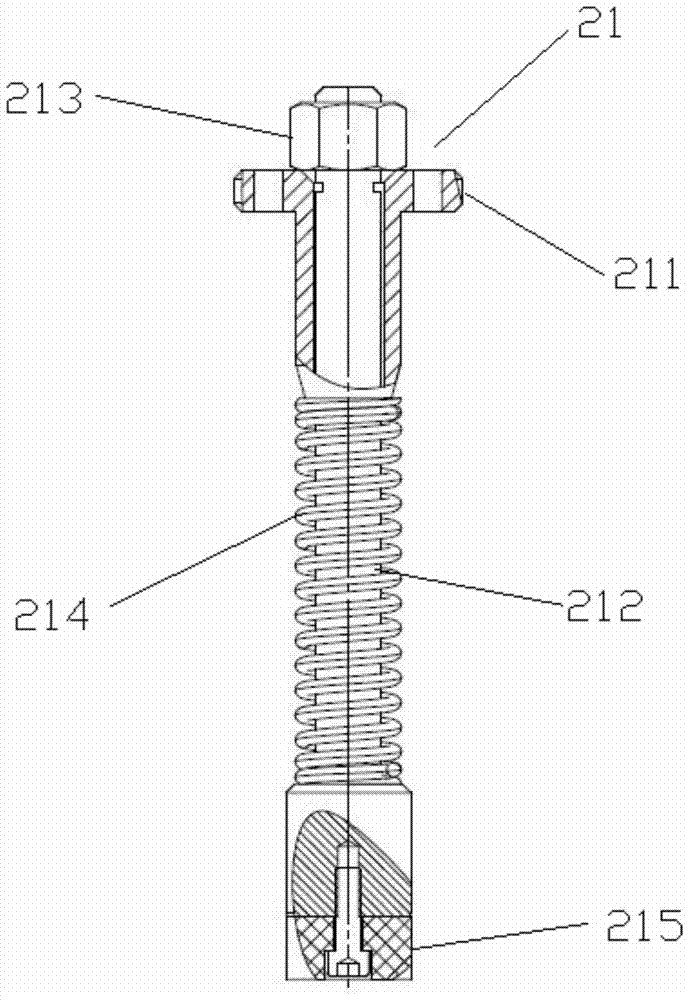

[0027] refer to figure 1 , the preferred embodiment of the present invention provides a vision-based robot handling fixture for the cylinder head of the engine, including a fixture body for clamping the cylinder head, the fixture body is connected with the handling robot body, and the fixture body is provided. Cylinder head 6 and the visual system for obtaining the position coordinates of the cylinder head 1, the detection system 2 for judging whether the clamp body is in place before carrying the cylinder head, and the air control system for controlling the clamp body to clamp the cylinder head; vision system 1, detection system 2 and the air control system are all connected with the control system of the handling robot. When the vision-based robo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com