Array substrate, liquid crystal display device and manufacturing method for array substrate

A technology of liquid crystal display devices and array substrates, applied in nonlinear optics, instruments, optics, etc., can solve problems affecting display quality, reducing brightness, etc., and achieve the effect of improving the display effect of large viewing angles, increasing brightness, and flexible range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

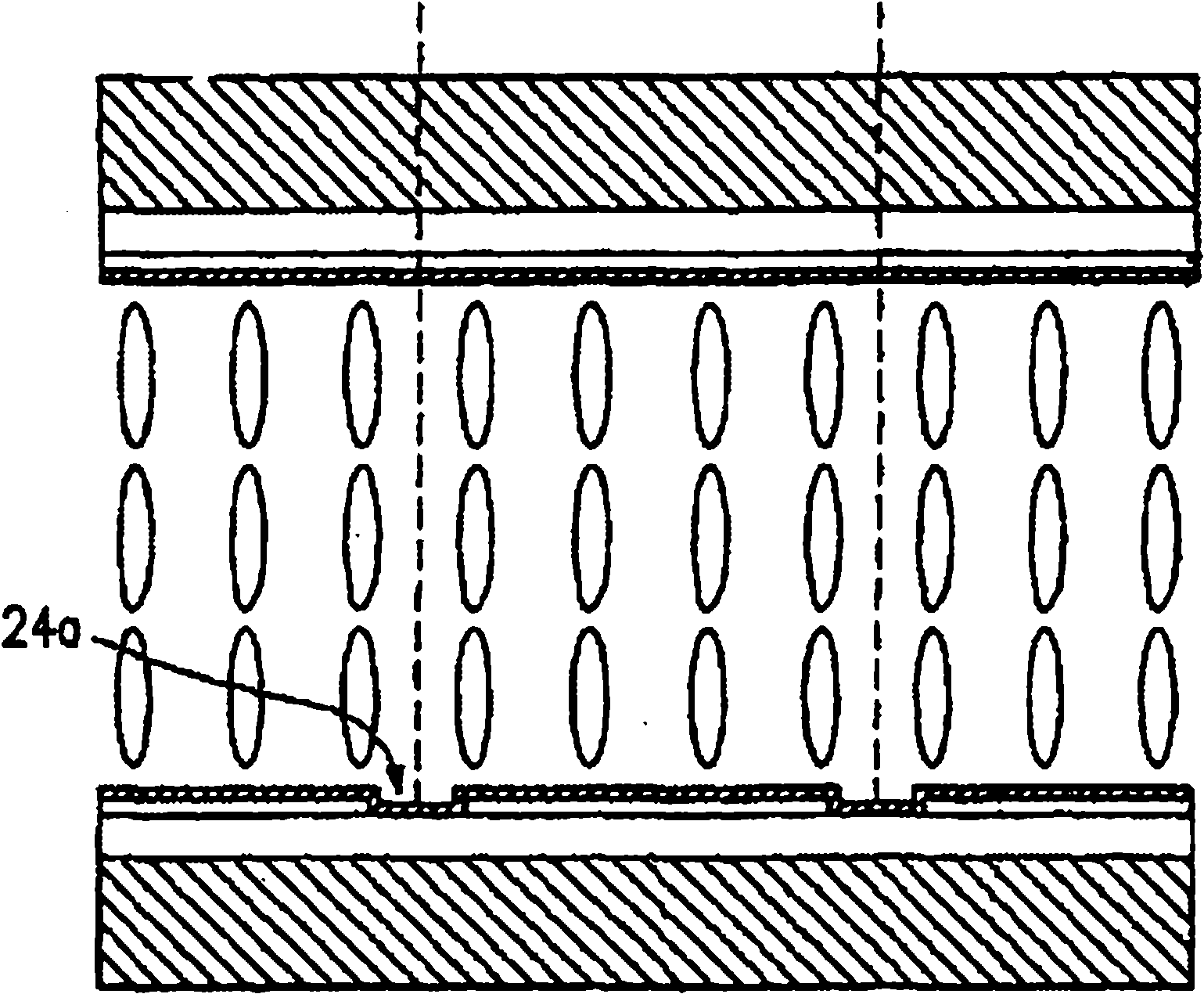

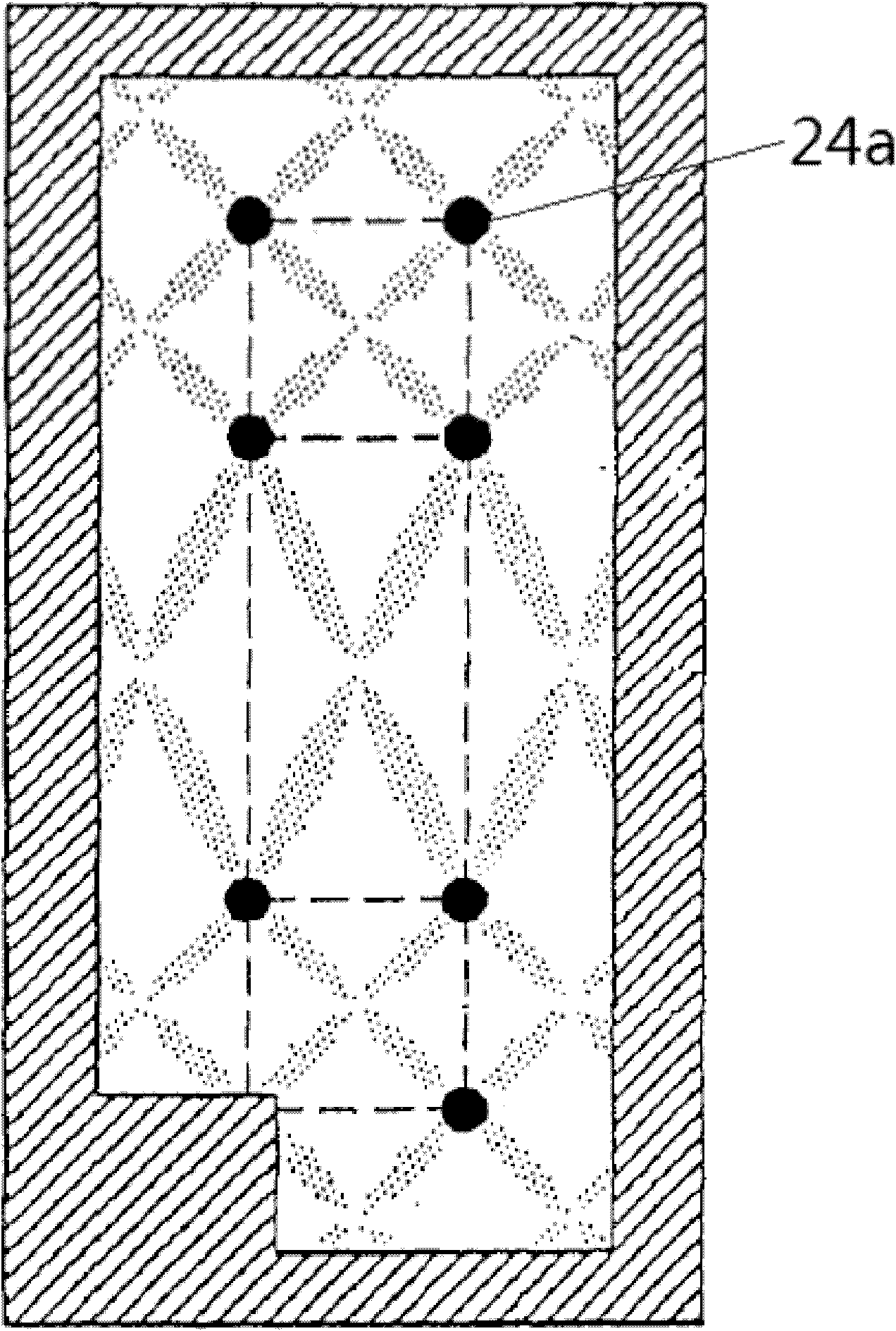

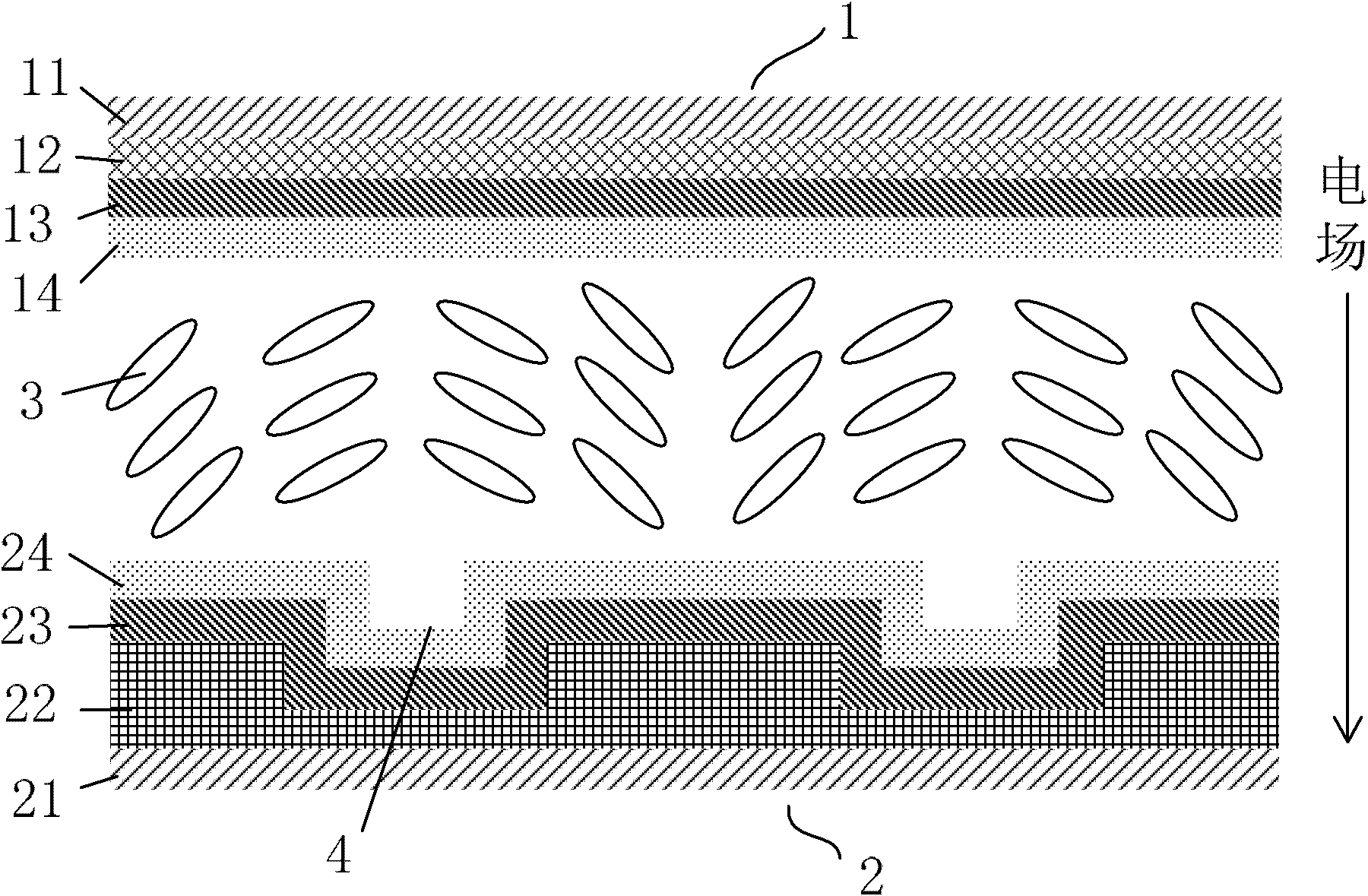

[0032] Embodiment one: if image 3 As shown, the array substrate 2 includes a first transparent substrate 21, a first insulating layer 22 covering the surface of the first transparent substrate 21, an electrode layer covering the surface of the first insulating layer 22 formed with a plurality of pixel electrodes 23, The first alignment film 24 covering the surface of the pixel electrode 23; the color filter substrate 1 includes a second transparent substrate 11, a color filter plate 12 covering the surface of the second transparent substrate 11, and a counter electrode covering the surface of the color filter plate 12 13. A second alignment film 14 covering the surface of the counter electrode 13 . There are multiple recessed regions on the first insulating layer 22 , and correspondingly, the electrode layer and the first alignment film 24 are also recessed inwards in the recessed regions, and the recessed regions are the field changing regions 4 . The distance between the p...

Embodiment 2

[0039] Embodiment two: if Figure 4 As shown, the array substrate 2 includes a first transparent substrate 21, a first insulating layer 22 covering the surface of the first transparent substrate 21, an electrode layer covering a plurality of pixel electrodes 23 formed on the surface of the first insulating layer 22, and an additional The second insulating layer 25 covering the surface of the electrode layer, and the first alignment film 24 covering the surface of the second insulating layer 25; the color filter substrate 1 includes a second transparent substrate 11, a The color filter plate 12 , the counter electrode 13 covering the surface of the color filter plate 12 , and the second alignment film 14 covering the surface of the counter electrode 13 . The second insulating layer 25 has a plurality of recessed regions, and the first alignment film 24 is also recessed in this region, and the recessed regions are the field changing regions 4, between the surface of the field ch...

Embodiment 3

[0046] Embodiment three: as Figure 5 As shown, the array substrate 2 includes a first transparent substrate 21, a first insulating layer 22 covering the surface of the first transparent substrate 21, an electrode layer covering the surface of the first insulating layer 22 formed with a plurality of pixel electrodes 23, The first alignment film 24 covering the surface of the pixel electrode 23; the color filter substrate 1 includes a second transparent substrate 11, a color filter plate 12 covering the surface of the second transparent substrate 11, and a counter electrode covering the surface of the color filter plate 12 13. A second alignment film 14 covering the surface of the counter electrode 13 . The first insulating layer 22 has a plurality of raised areas, and correspondingly, the electrode layer and the first alignment film 24 are also raised outwards in the raised areas, and the raised areas are the field-changing areas 4. The distance between the pixel electrode 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com