Movable contact part and switch device

A technology for moving contacts and components, applied in electrical switches, electrical components, circuits, etc., can solve the problems of cracks in the notch and inability to have life performance, and achieve the effect of reducing stress amplitude and realizing miniaturization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

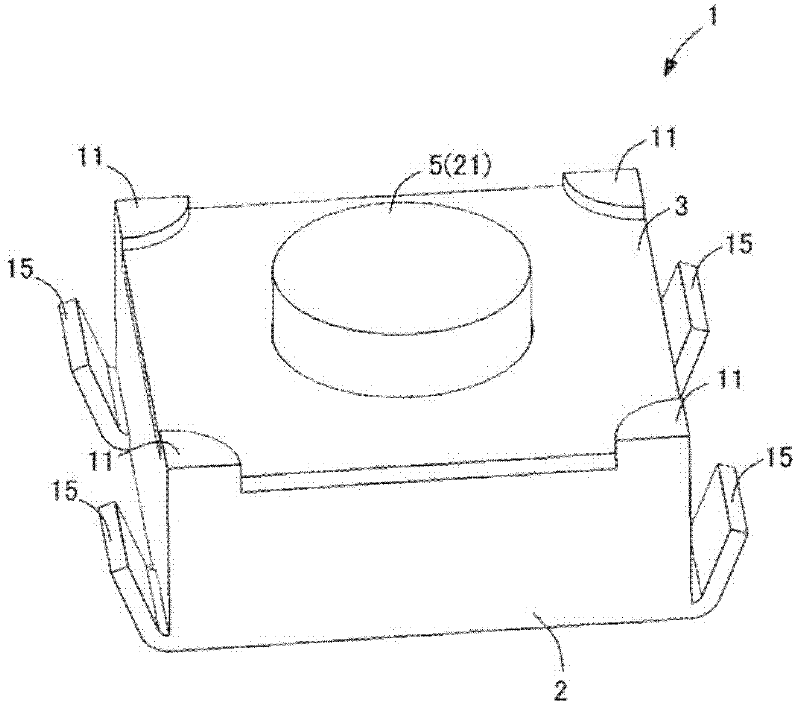

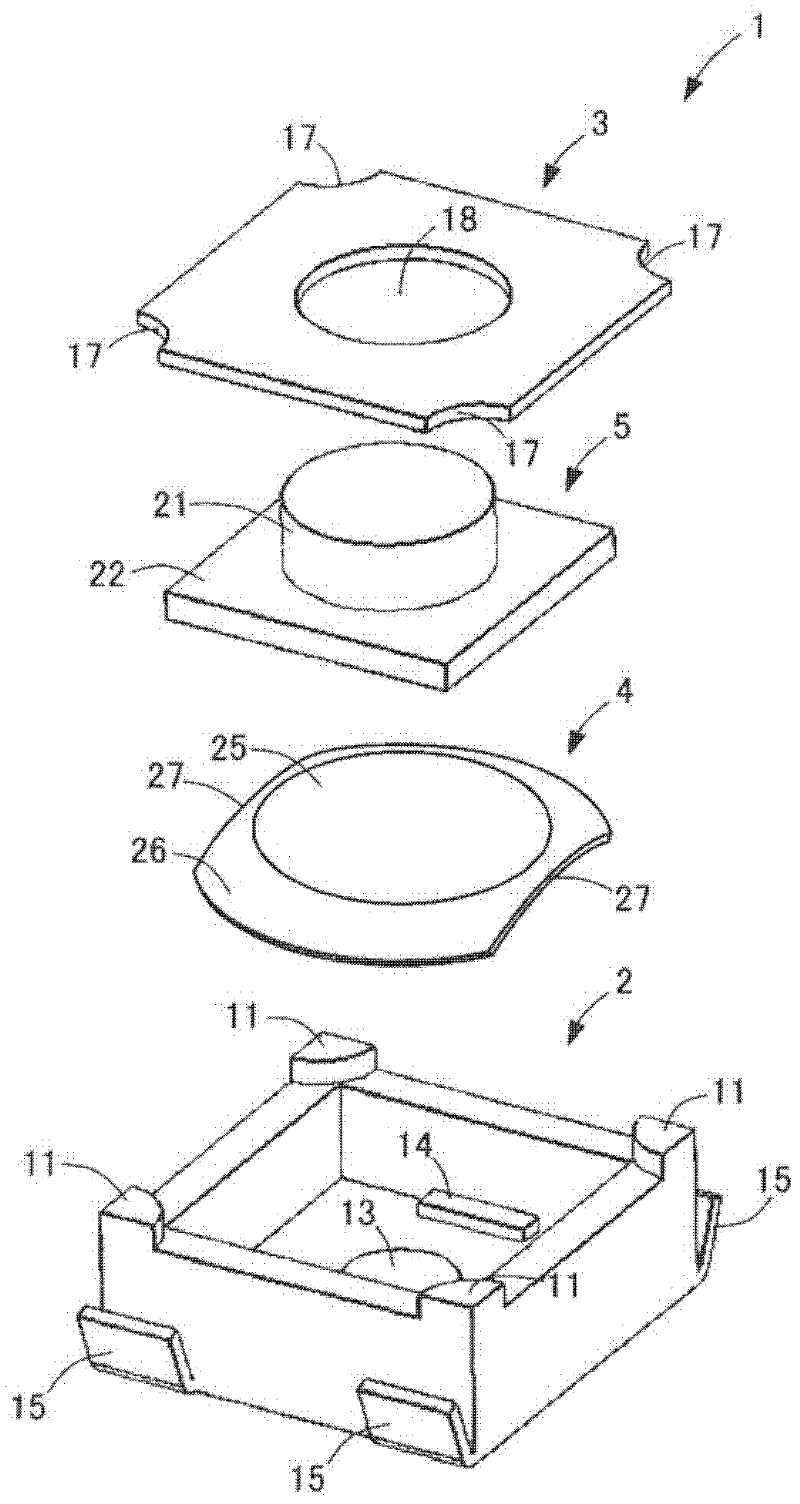

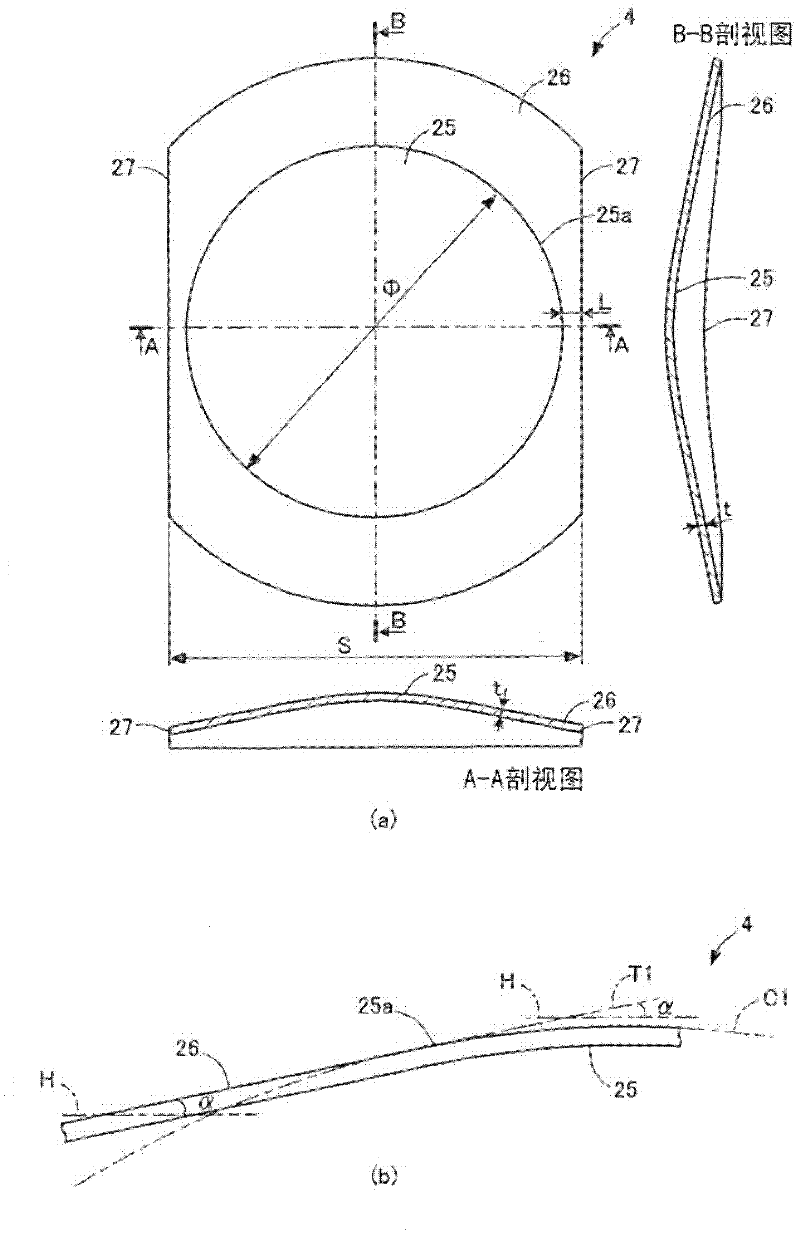

[0054] As a movable contact member used in a switchgear, a structure combining an arch-shaped raised portion and a skirt connected to the raised portion has been proposed. In the switchgear according to the present invention, the miniaturization of the movable contact member is desired along with the miniaturization of electronic equipment. Generally, when reducing the size of the movable contact member, the raised portion is cut together with the skirt portion to provide a pair of opposing notches, thereby reducing the size of the movable contact member. However, in this movable contact member, cracks tend to occur from the pair of notches, making it difficult to achieve a longer life.

[0055] Here, the present applicant investigated the relationship between the formation positions of the pair of notches and the life of the movable contact member (here, the number of times of repeated pressing operations in which cracks occur on the movable contact member), and as a result, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com