Method for polishing silicon through hole wafer and polishing combination for the same

A polishing composition and a technology for through-silicon vias, which are applied in the polishing field, can solve the problem that the difference in removal rate is too large, the polishing rate of silicon and conductive materials is increased, and it is not suitable for polishing composition components that can polish silicon and conductive materials at the same time. problems to achieve reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The polishing method of the TSV wafer of the present invention includes polishing the surface of the TSV wafer with the above-mentioned polishing composition of the present invention. When the polishing process is carried out, the polishing composition flows to the polishing pad and the TSV wafer at a flow rate, and at the same time, the TSV wafer is applied with a polishing pressure to contact the polishing pad, and the two have a rotational speed respectively, so that the The TSV wafer is polished.

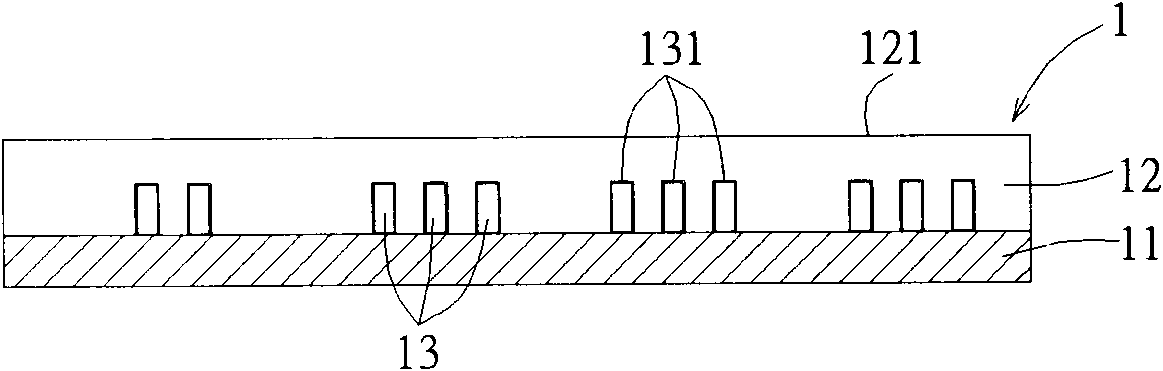

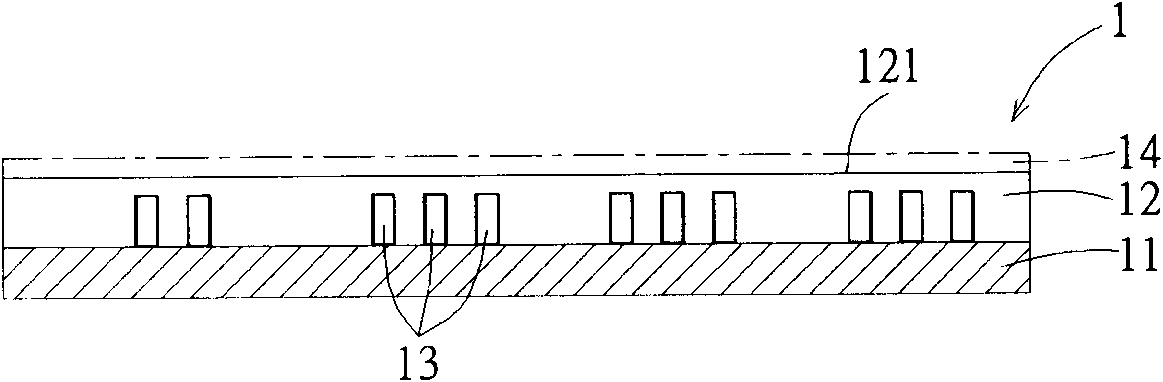

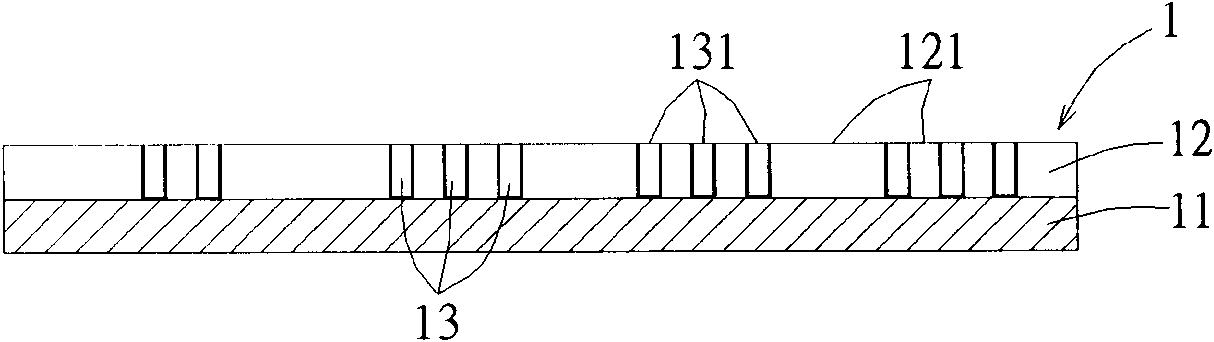

[0025] It must first be explained that the above-mentioned "surface of the TSV wafer" means a surface of the TSV wafer far away from its integrated circuit layer 11, which may be the surface 121 of the silicon wafer layer (such as figure 1 shown) or together with the top surface 131 of the conductive material (such as image 3 shown).

[0026] In this mode of operation, the removal rate of conductive material and silicon on the TSV wafer can reach more than, even mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com