Dustproof barrel for spray gun

A technology of dust-proof material and spray gun, which is applied in the direction of the spray device, etc., can solve the problems of blockage of the air pressure hole, suction of raw materials in the tank, reduction of air pressure, etc., and achieve the effect of improving the absorption effect and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

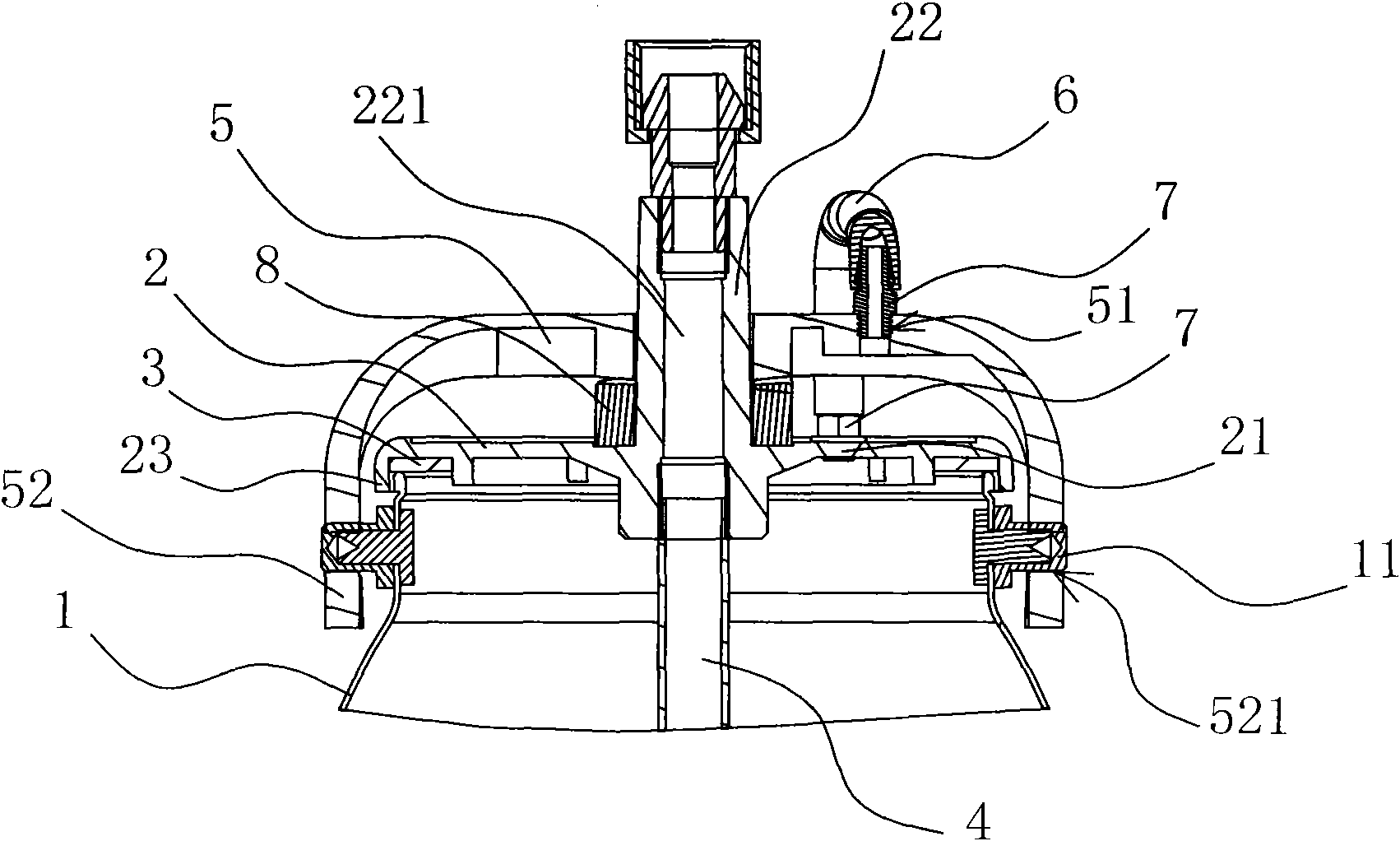

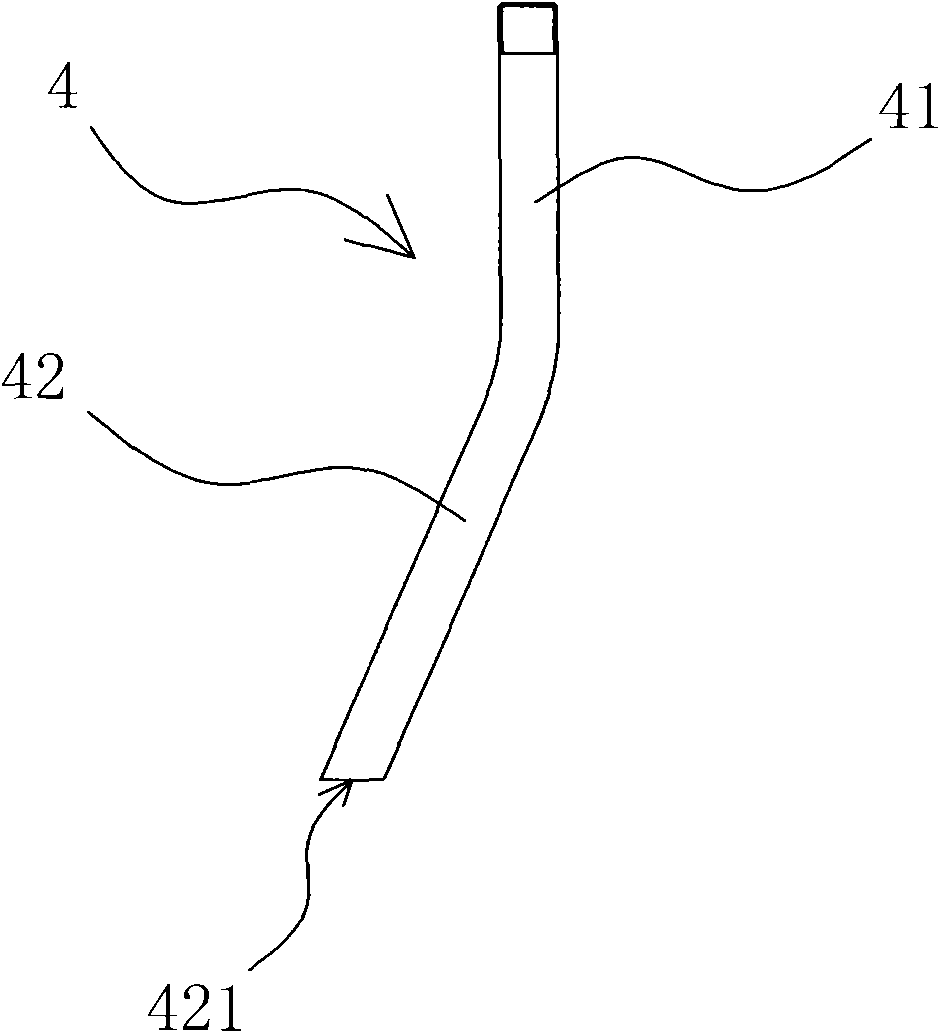

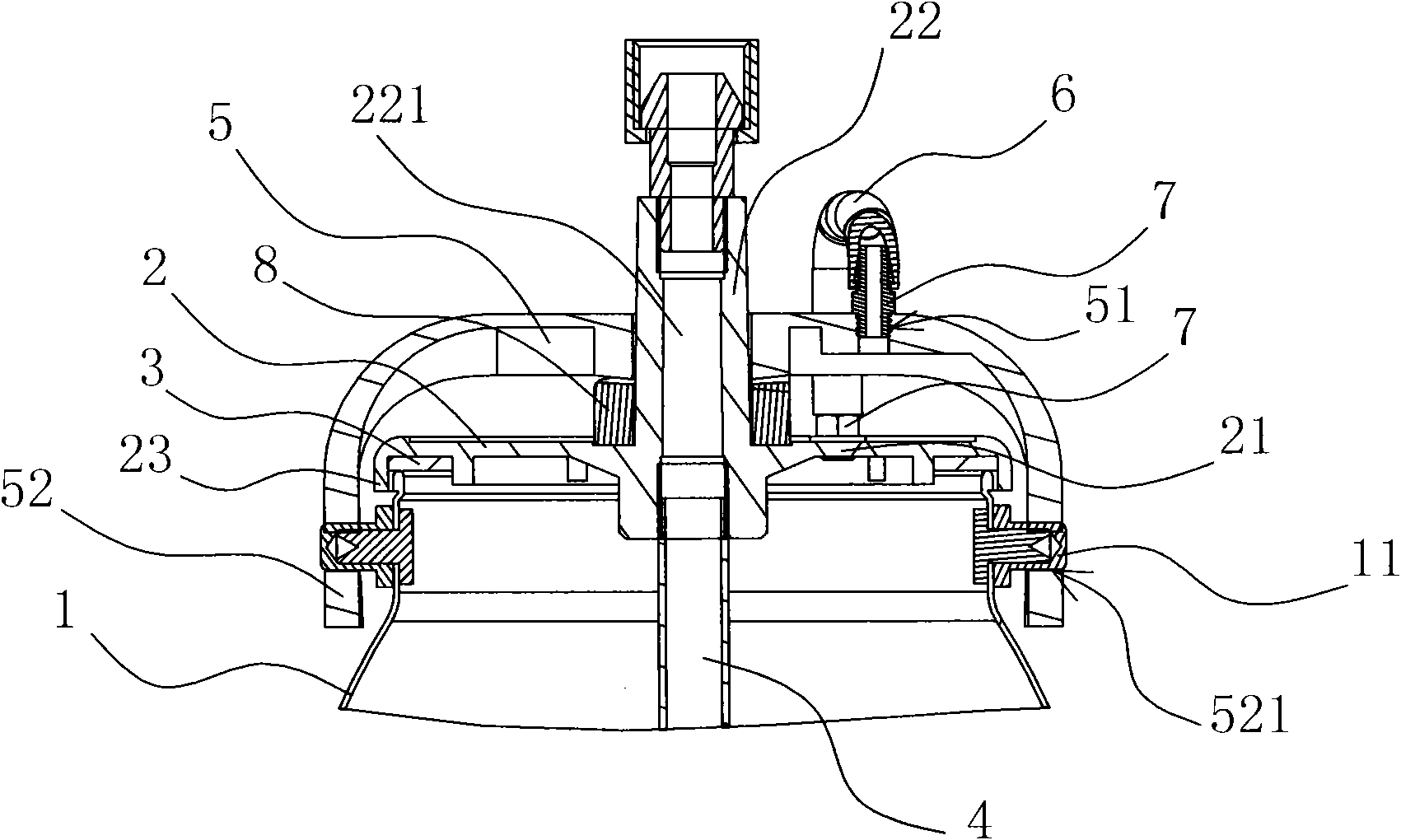

[0026] Such as figure 1 and 2 As shown, the dust-proof tank of this spray gun comprises a tank 1 with a tank mouth and a tank cover 2 sealedly connected with the tank mouth, a sealing ring 3 is arranged between the tank cover 2 and the tank mouth, and a seal ring 3 is arranged around the tank cover 2. The edge extends downwards to form a rim 23 and buckles on the outer side of the mouth of the tank. There is an air pressure hole 21 on the material tank cover 2, and a connecting part 22 perpendicular to the material tank cover 2 is arranged in the middle. There is a material through hole 221 in the connecting part 22, and a suction pipe 4 is arranged in the material tank 1, and the suction pipe 4 includes a straight part. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com