Synchronously lifted supporting leg

A synchronous lifting and outrigger technology, applied in the direction of lifting vehicle parts, vehicle maintenance, transportation and packaging, can solve the problems of difficult maintenance, easy to slide down and displacement, unable to work stably, and achieve short lifting time, The effect of improving the stability of the base station and improving the security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific examples, but the present invention is not limited to these specific implementations. Those skilled in the art will realize that the present invention covers all alternatives, modifications and equivalents as may be included within the scope of the claims.

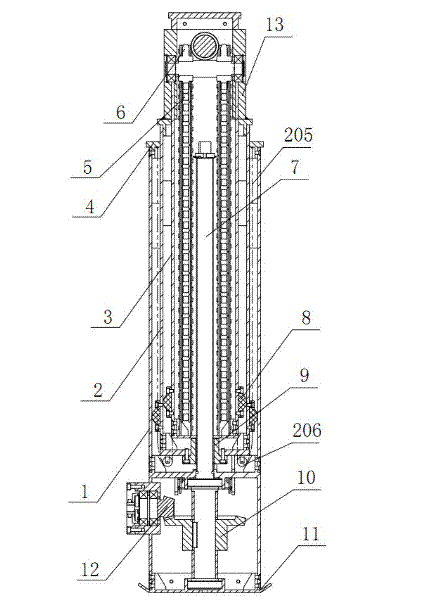

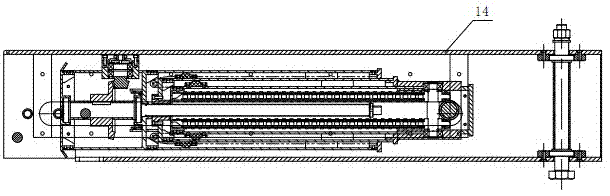

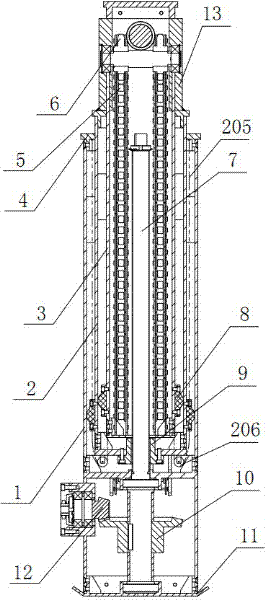

[0033] see figure 1 , figure 2 , a synchronous lifting leg, including n joint arms that are sequentially socketed from outside to inside base joint arm 1, second joint arm 2, third joint arm 3, ???, n joint arms, n≥3, the base The bottom of the joint arm 1 is connected with the bottom plate 11 placed on the ground, and a screw rod 7 is pierced in the joint arm, and a nut 9 is set on the screw rod 7, and the nut 9 is connected with the bottom of the second joint arm 2. The screw rod 7 is connected with the driver that drives it to rotate, and a plurality of sprockets 6 are installed on the upper end of the i joint arm, i≥2, each of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com