Artillery barrel bore detecting system

A detection system and artillery barrel technology, which are used in weapons testing, weapon accessories, offensive equipment, etc., can solve the problems of large deviation and difference in the axis of the centering device, and it is impossible to find out the specific condition of the inner bore surface, so as to ensure the measurement accuracy. 、Reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

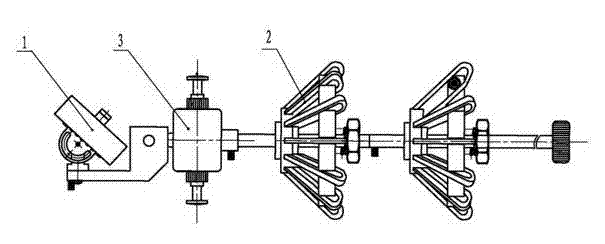

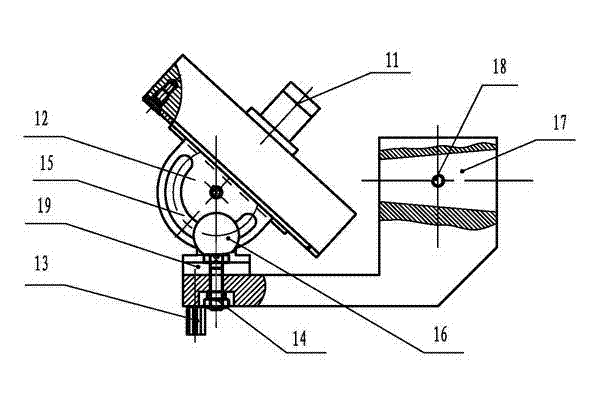

[0015] figure 1 Shown is the inspection system for the inner bore of the gun barrel, including the centering mechanism 2 installed on the shaft, the inner diameter measuring mechanism 3 and the bore sighting mechanism 1 .

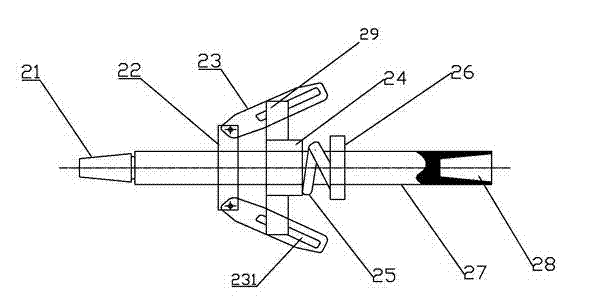

[0016] image 3 As shown, the centering mechanism 2 includes a fixed plate 22 fixed on the shaft 27, a number of umbrella ribs 23 whose ends are hinged to the fixed plate and distributed around the fixed plate, and a set of ribs installed on the shaft 27. An elastic support mechanism for spreading the ribs. Described elastic supporting mechanism comprises a sliding block 24 that is slidably connected on the shaft rod 27, the spring 25 that is sleeved on the shaft rod 27 and the limiting block 26 that is fixedly connected on the shaft rod, and the spring is located between the sliding block and the limiting block. between bit blocks. The limiting block 26 is fixed on the shaft with fasteners, and the spring force can be adjusted by adjusting the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com