Apparatus for actuating a positive shifting element shiftable at least between two shifting positions

A technology for shifting elements and gear postures, applied to elements with teeth, transmission control, belts/chains/gears, etc., which can solve problems such as high sealing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

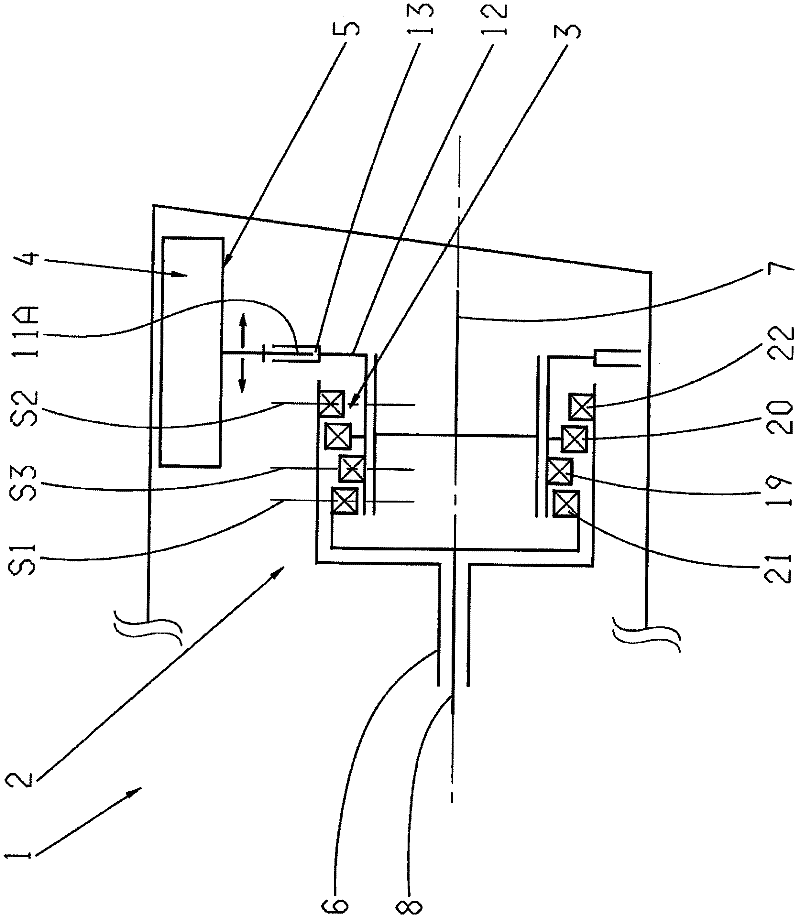

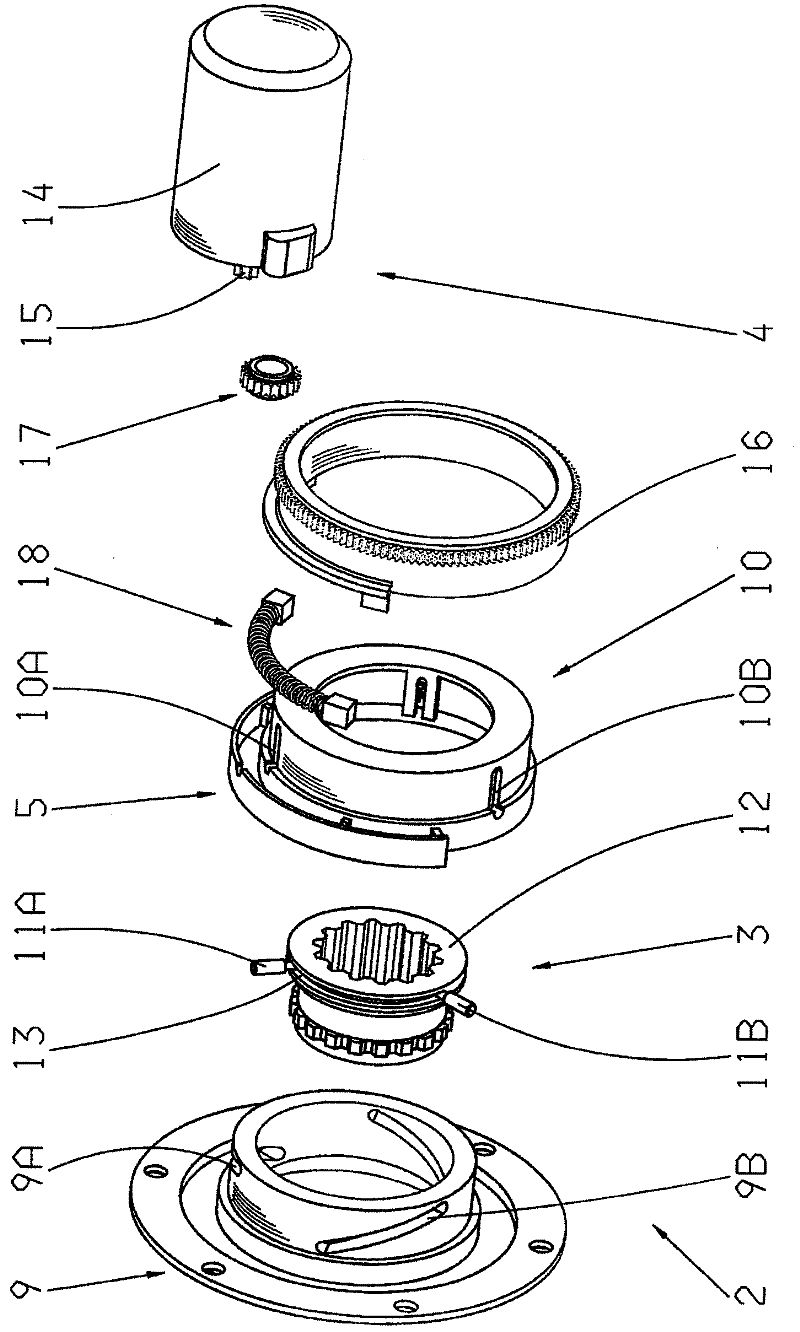

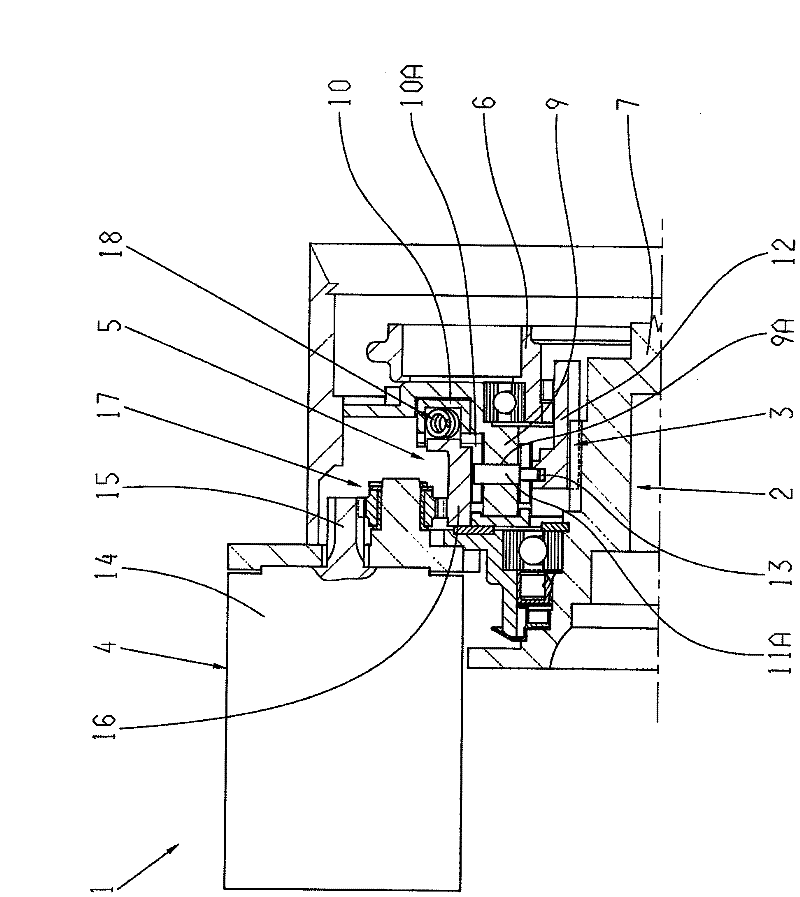

[0034] figure 1 Shown is a transmission device 1 with a device 2 for actuating form-locking shifting elements that can be shifted between three shifting positions S1, S2 and S3, with a drive device 4 and figure 2 and image 3 The drive conversion device 5 shown in detail in FIG. 2 is used to convert the rotational drive movement of the drive device 4 into a translational operating movement of the form-fitting shifting element.

[0035] Both in the first shifting position S1 and in the second shifting position S2, the two transmission shafts 6 and 7 or 7 and 8 are connected to each other in a rotationally fixed manner via the form-locking shifting element 3 , while in the first shifting position S1 and in the second shifting position S2 In the third shifting position S3 of the shifting element 3 , the transmission shafts 6 and 7 or 7 and 8 are separated from each other.

[0036] The drive conversion device 5 comprises a first structural element 9 with three control curves 9A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com