Separation system for brewing wine

A separation system and transfer pipe technology, applied in the field of separation systems for wine making, can solve the problems of low production efficiency, inability to achieve very good separation effects, and inability to complete long-distance transmission and large-scale production, and achieve the convenience of handling impurities, Better solid-liquid separation effect and better wine quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

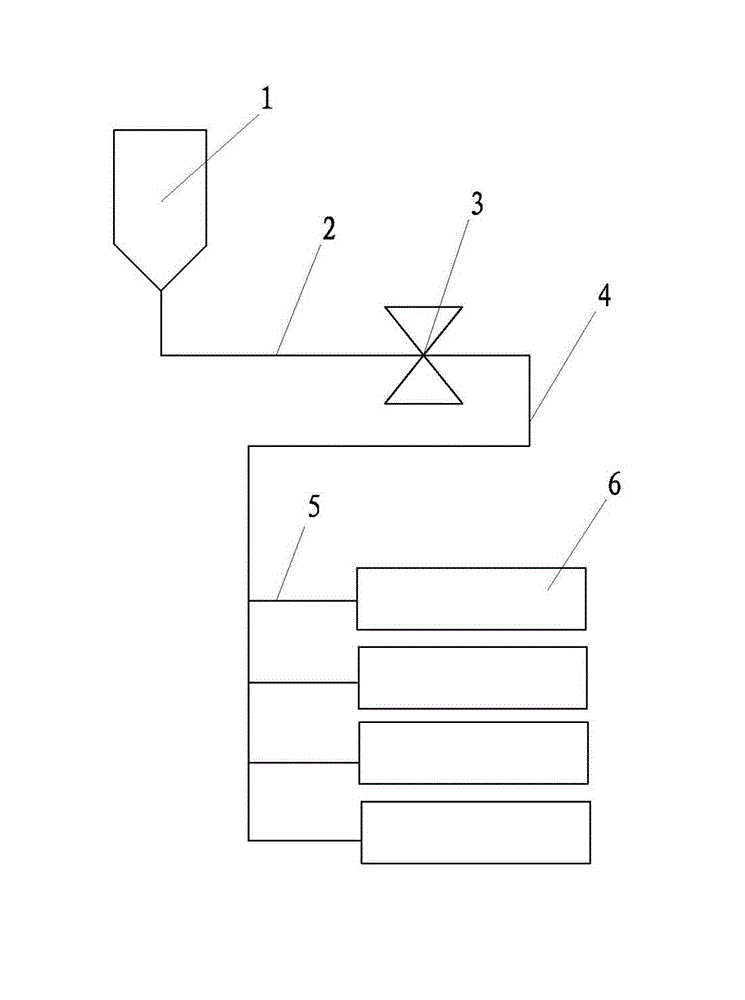

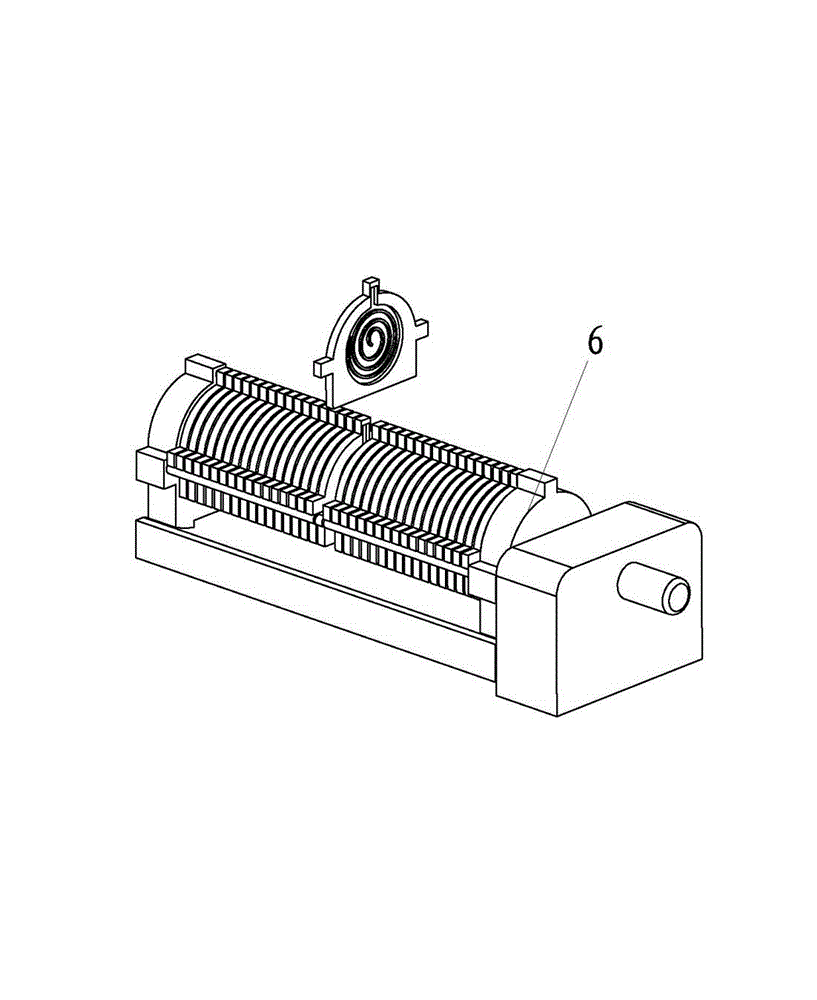

[0016] Embodiment one, such as figure 1 , figure 2 , image 3 As shown, the separation system for wine making includes a fermenter 1, a transfer pipe 2 and a press 6. One end of the transfer pipe 2 is connected to the fermenter 1, and the other end of the transfer pipe 2 is connected to the pump station 3, and the pump station 3 is connected with an output The pipe 4 and the pumping station 3 are provided with two pumps, and there are also transmission branch pipes and output branch pipes matching each pump. The transmission branch pipe is connected to the transmission pipe 2, and the output branch pipe is connected to the output pipe 4. It communicates with the press 6, and the height of the output pipe 4 is higher than that of the press 6.

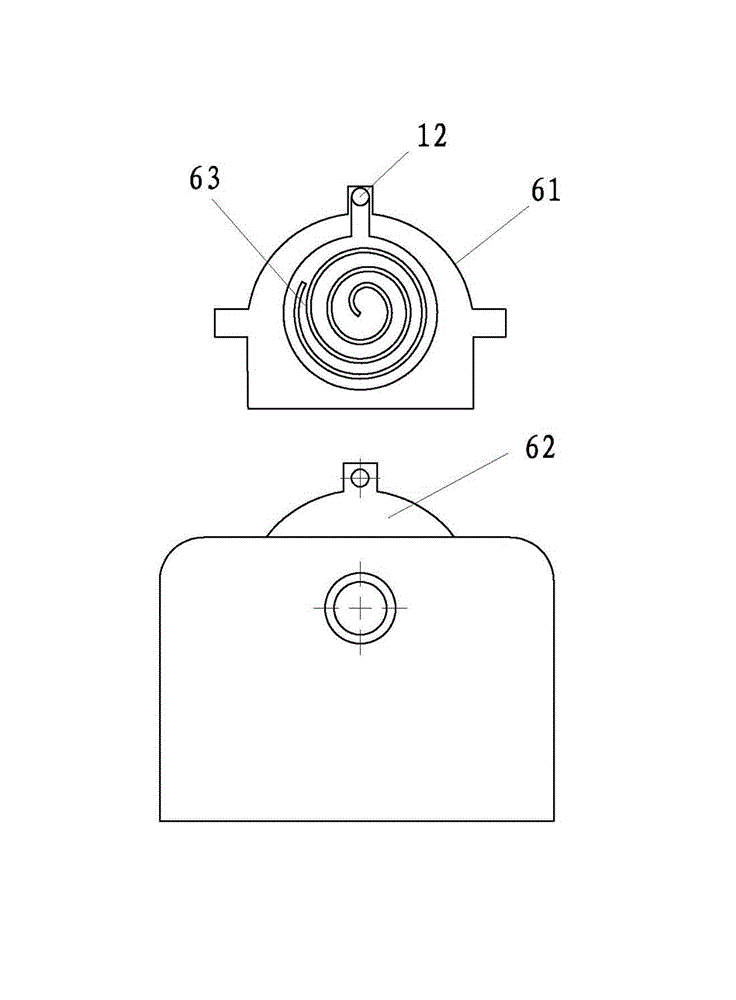

[0017] The press 6 is provided with a convex plate 61 and a concave plate 62, the convex plate 61 and the concave plate 62 are closely arranged together in turn, and the convex plate 61 and the concave plate 62 are provided with circu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com