Electric tea screening machine

An electric sieve and tea technology, which is applied in the direction of solid separation, tea treatment before extraction, and separation of solids from solids with airflow, can solve the problems of uneven thickness of tea leaves, many impurities, low efficiency, etc., and achieve improved screening Efficiency, broad market prospects, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

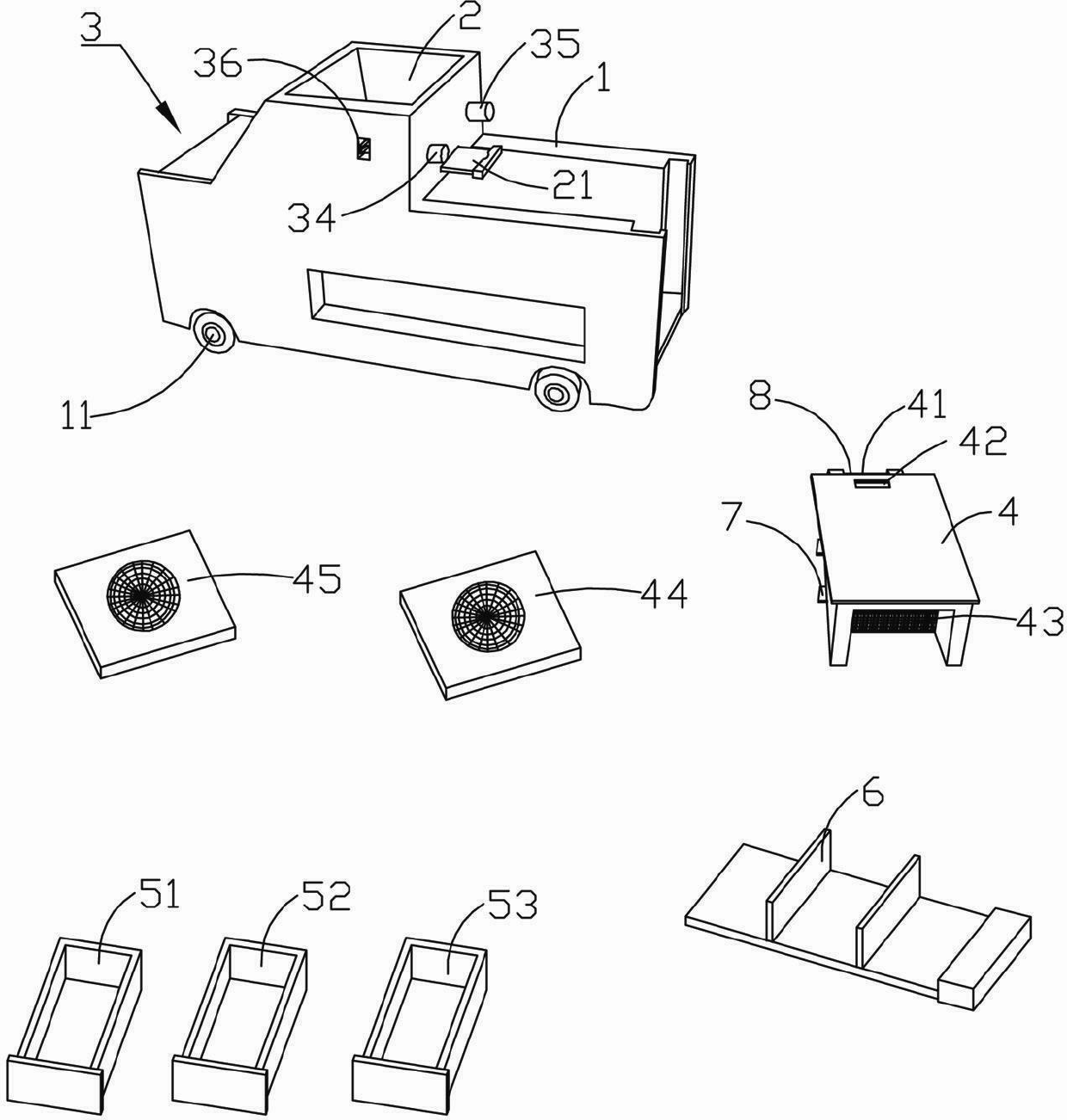

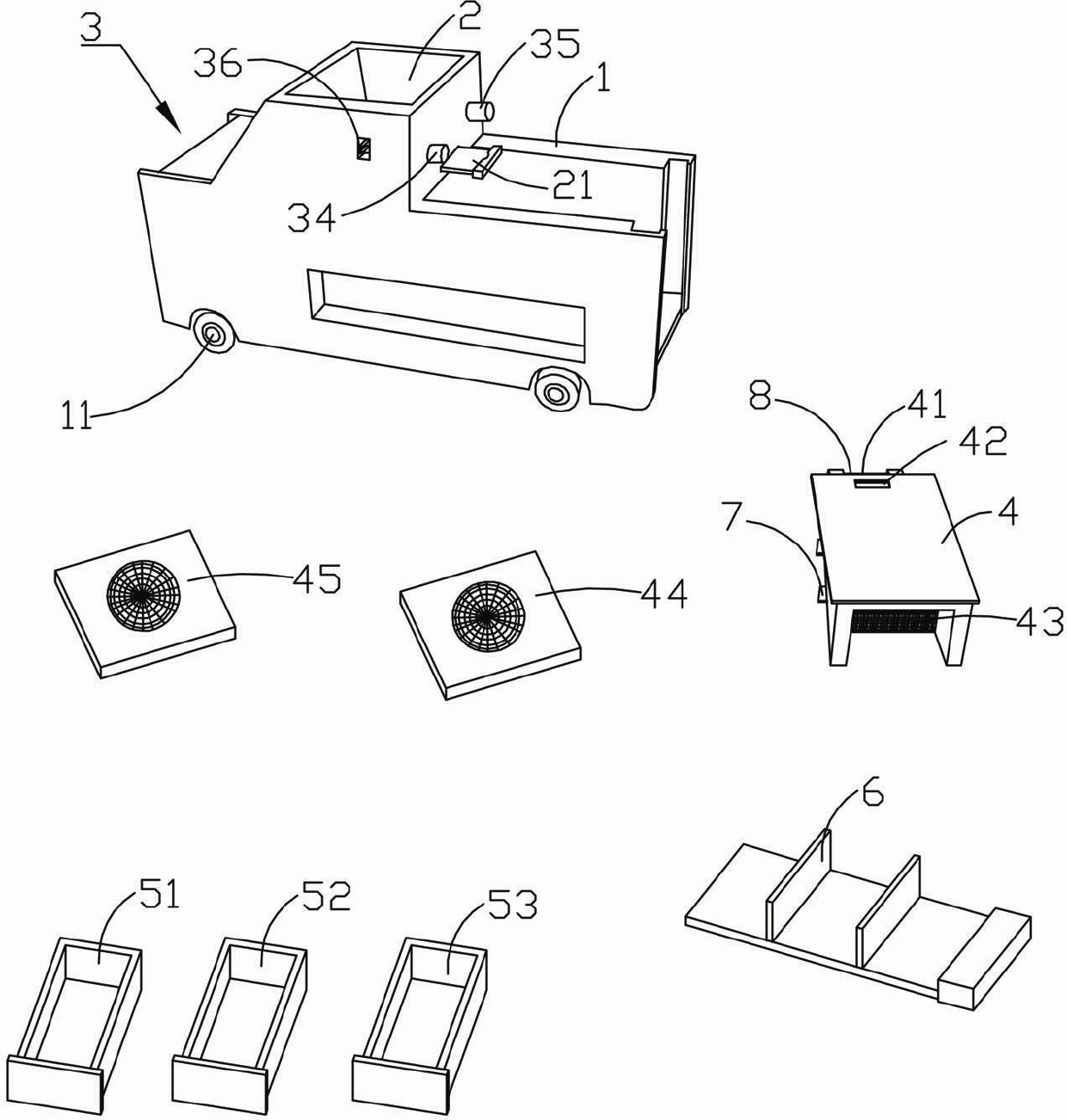

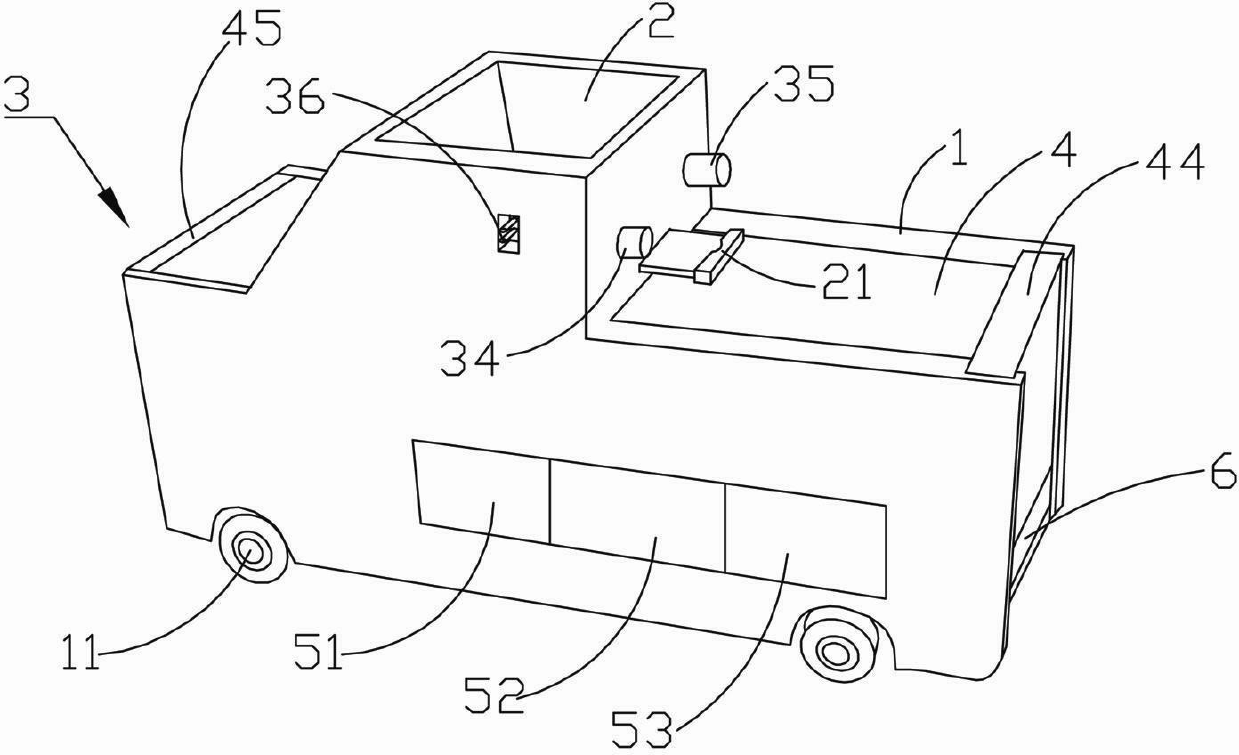

[0025] refer to figure 1 , figure 2 . An electric tea screening machine, comprising a bracket 1, a funnel 2 arranged on the bracket 1, an air outlet device 3 located on the side below the funnel 2, and an air duct 4 located below the funnel 2 and extending away from the air outlet device 3 And be positioned at three drawers below the air duct 4, the first drawer 51, the second drawer 52, the third drawer 53, between the adjacent drawers separated by the partition plate 6, the air inlet 41 of the air duct 4 and the air outlet device 3 Correspondingly, the air duct 4 is provided with a material inlet 42 corresponding to the outlet 21 of the funnel 2 , and the air duct 4 gradually becomes larger along the direction away from the air outlet device 3 . The position corresponding to the edge of the third drawer 53 on the air duct 4 is provided with a gauze ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap