Stereo molding device of shell fabric

A three-dimensional, molding technology, applied in the direction of sewing tools and other directions, can solve the problems of fabric stretching and tissue damage, unbalanced tension, damage and other problems, and achieve the effect of wide applicability and balanced stretching.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

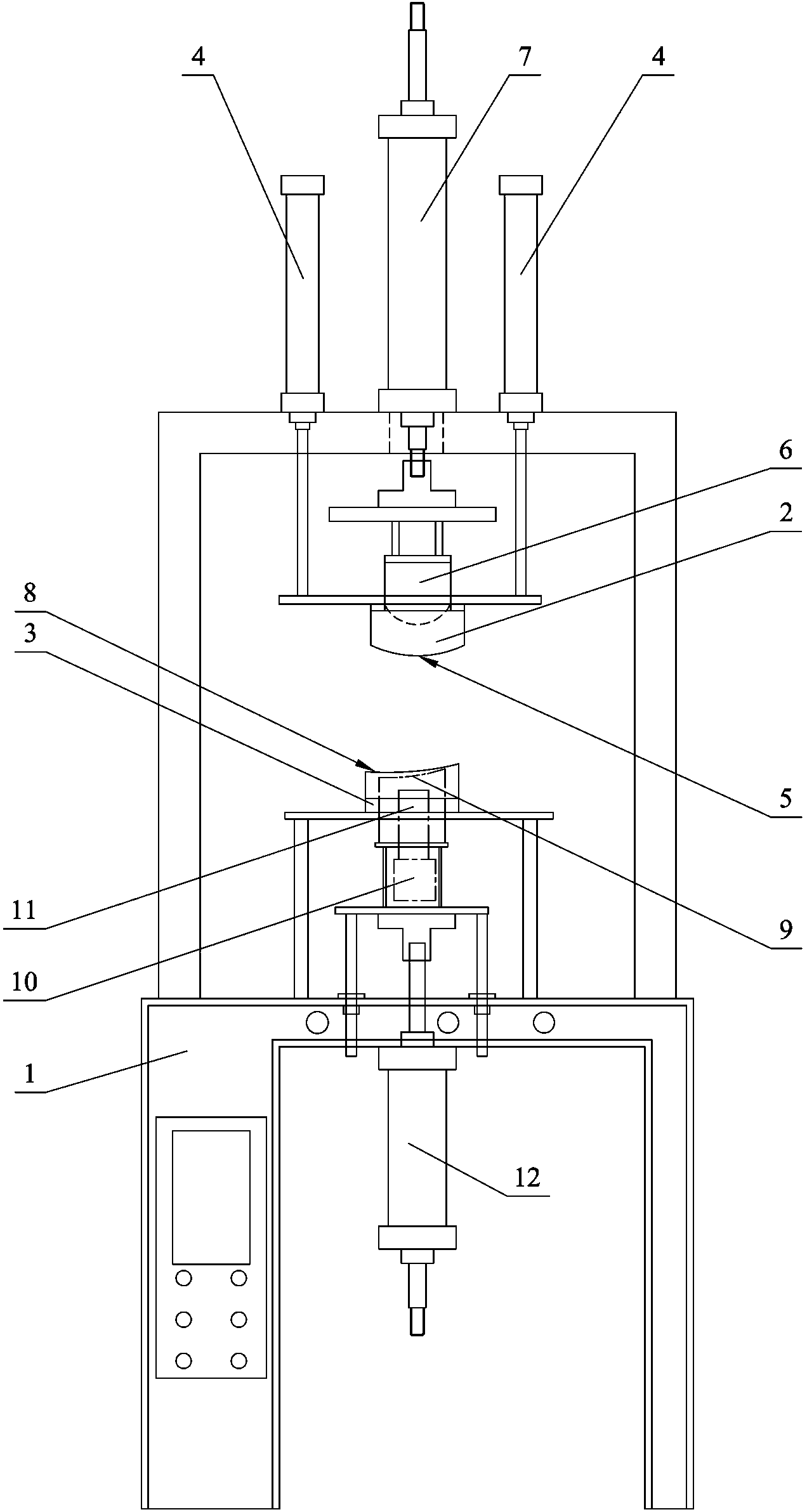

[0016] Embodiment one: see attached figure 1 shown.

[0017] A three-dimensional molding device for face cloth, comprising a frame 1, an upper mold 2 movably installed on the frame 1 and having an upper mold cavity, and a lower mold 3 fixedly installed on the frame 1 and having a lower mold cavity.

[0018] The upper mold 2 is provided with a third air cylinder 4 that drives it to move vertically. The bottom of patrix 2 has first curved surface 5, is provided with the special-shaped bullet mold 6 that can move in vertical direction in the patrix cavity, and its molding is consistent with the moulding that required molding is formed, makes the surface cloth after molding The fit between the product and the cup is higher. The special-shaped bullet mold 6 is connected with the first air cylinder 7 that drives it to move.

[0019] The top of lower mold 3 has second arc-shaped surface 8, is provided with the grid bracket 9 that can move in vertical direction in the lower mold ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com