Low-temperature-resistant super-tough halogen-free flame-retardant nylon alloy and preparation method thereof

A technology of flame-retardant nylon and low-temperature resistance, which is applied in the field of low-temperature-resistant super-tough halogen-free nylon alloy and its preparation. The effect of performance decline, good coating and dispersion, and strong low-temperature impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

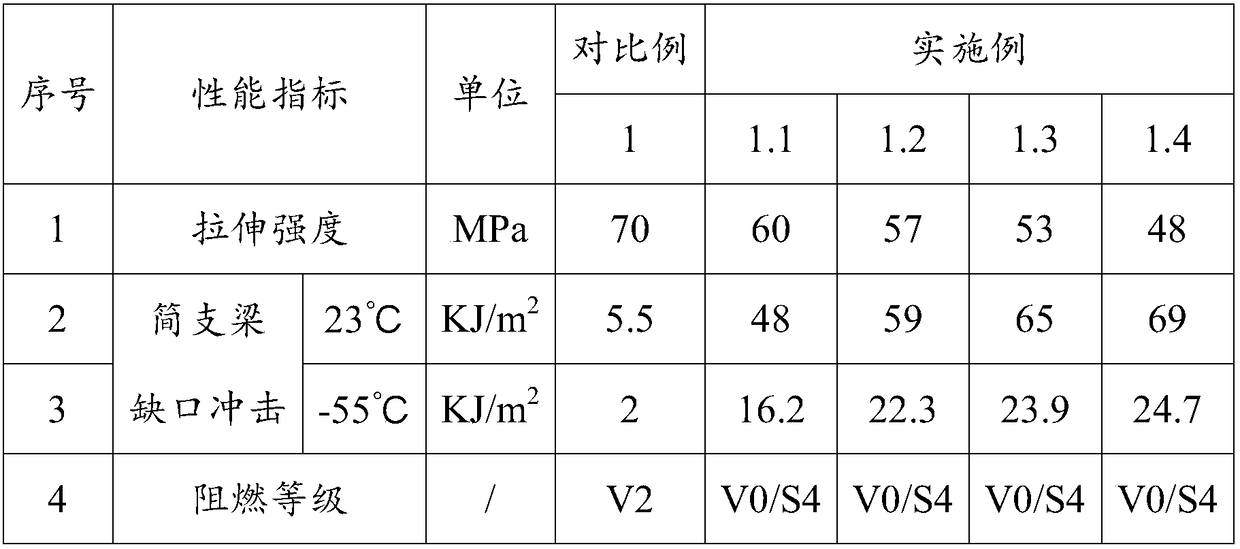

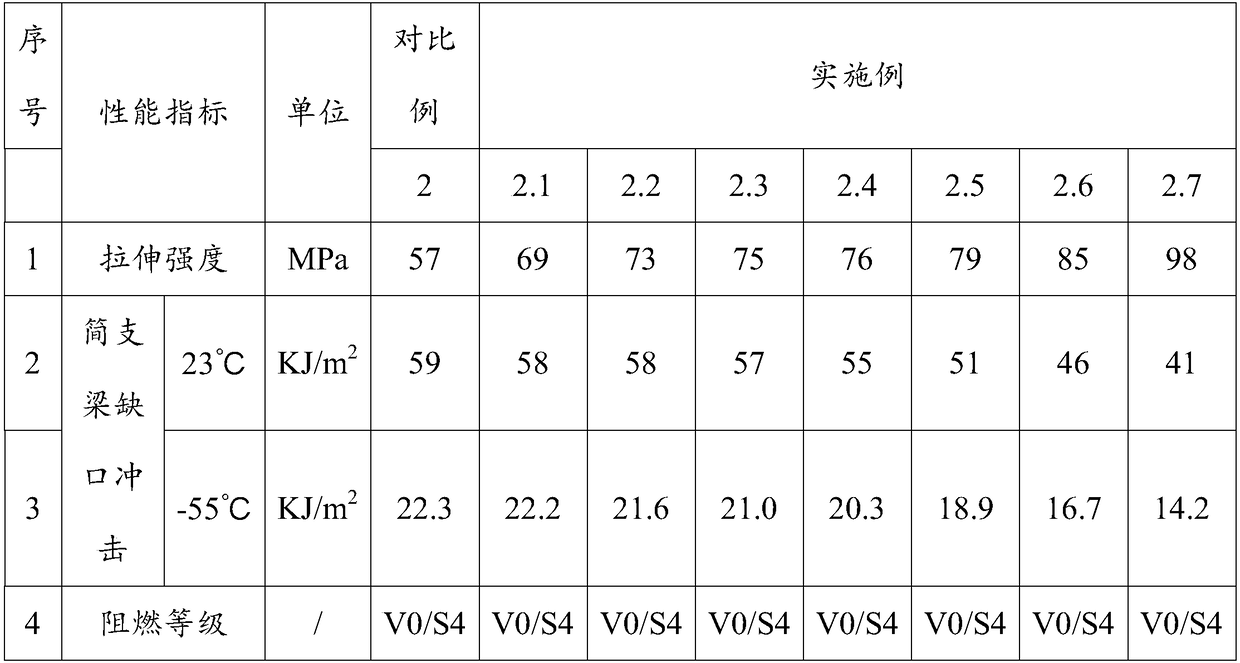

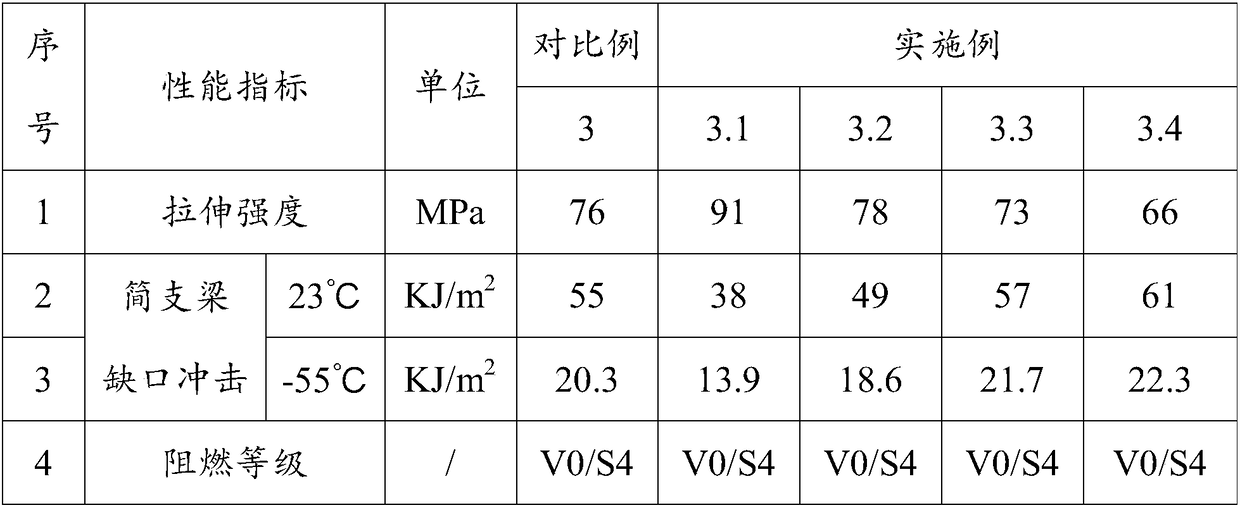

Examples

Embodiment 11

[0038]73 parts of nylon 6 (Xinhui Meida M2500), 10 parts of PE-g-MAH (Plasty ST-01), 7 parts of MCA (Sichuan Fine Chemical Industry), 1 part of antioxidant (1010), 1 part of light stabilizer (carbon black) and 1 part of processing aid, 1.5 parts of flame retardant synergist (pentaerythritol), after mixing in a high-speed mixer for 10 minutes, put them into the hopper of a twin-screw extruder, and the temperature in the first to third zones: 220~240 ℃, the temperature of zone four to six: 230~250℃, the temperature of zone seven to nine: 220~250℃, the main screw speed is 500 rpm, and the feeding screw speed is 50 rpm. Traction, cooling, pelletizing and drying.

Embodiment 12

[0040] 73 parts of nylon 6 (Xinhui Meida M2500), 15 parts of PE-g-MAH (Plasty ST-01), 7 parts of MCA (Sichuan Fine Chemical Industry), 1 part of antioxidant (1010), 1 part of light stabilizer (carbon black) and 1 part of processing aid, 1.5 parts of flame retardant synergist (pentaerythritol), after mixing in a high-speed mixer for 10 minutes, put them into the hopper of a twin-screw extruder, and the temperature in the first to third zones: 220~240 ℃, the temperature of zone four to six: 230~250℃, the temperature of zone seven to nine: 220~250℃, the main screw speed is 500 rpm, and the feeding screw speed is 50 rpm. Traction, cooling, pelletizing and drying.

Embodiment 13

[0042] 73 parts of nylon 6 (Xinhui Meida M2500), 20 parts of PE-g-MAH (Plastai ST-01), 7 parts of MCA (Sichuan Fine Chemical Industry), 1 part of antioxidant (1010), 1 part of light stabilizer (carbon black) and 1 part of processing aid, 1.5 parts of flame retardant synergist (pentaerythritol), after mixing in a high-speed mixer for 10 minutes, put the twin-screw into the hopper of the extruder, the temperature of the first to third zones: 220 ~ 240 ℃, the temperature of zone four to six: 230~250℃, the temperature of zone seven to nine: 220~250℃, the main screw speed is 500 rpm, and the feeding screw speed is 50 rpm. Traction, cooling, pelletizing and drying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com