A modified nylon composite material and its application

A nylon composite material and modification technology, which is applied in the field of nylon materials, can solve the problems of low melt fluidity requirements, poor welding compatibility, and insufficient welding strength, and achieve excellent resistance to fuel penetration, fire resistance, and sealing Good sex, avoid the effect of sharp decline

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

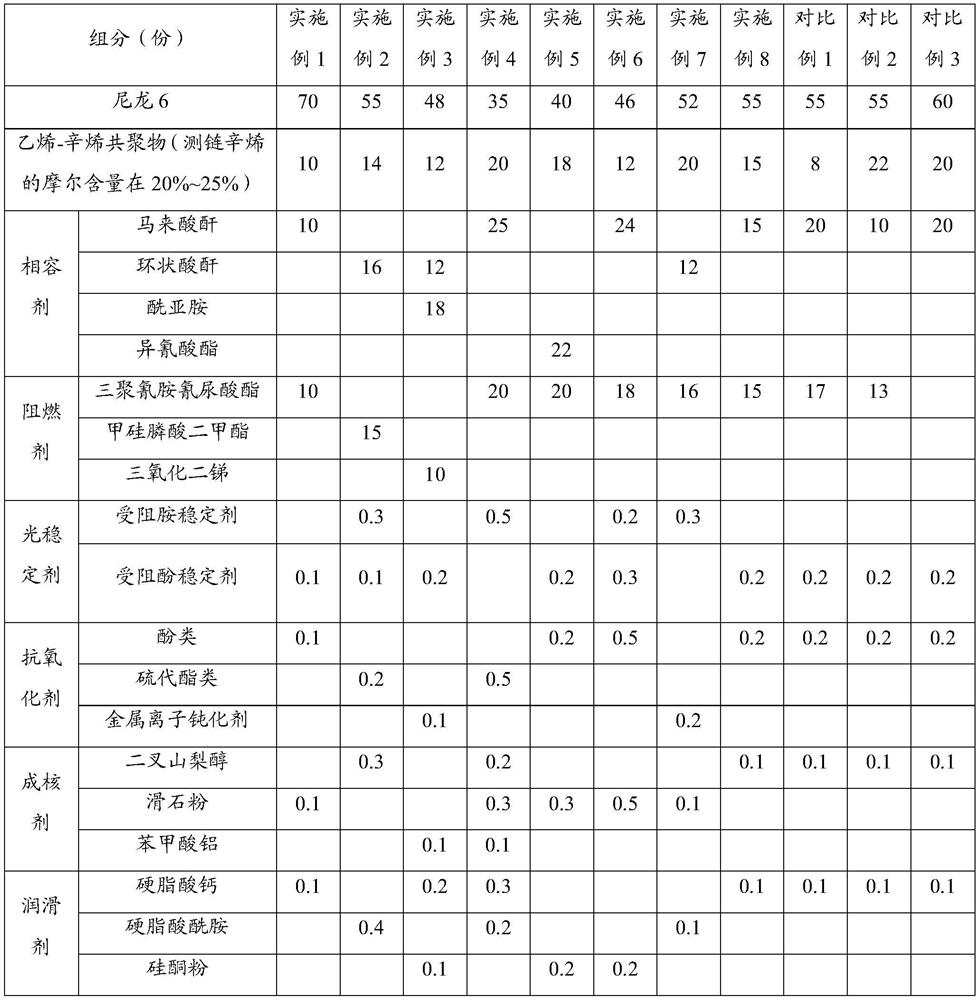

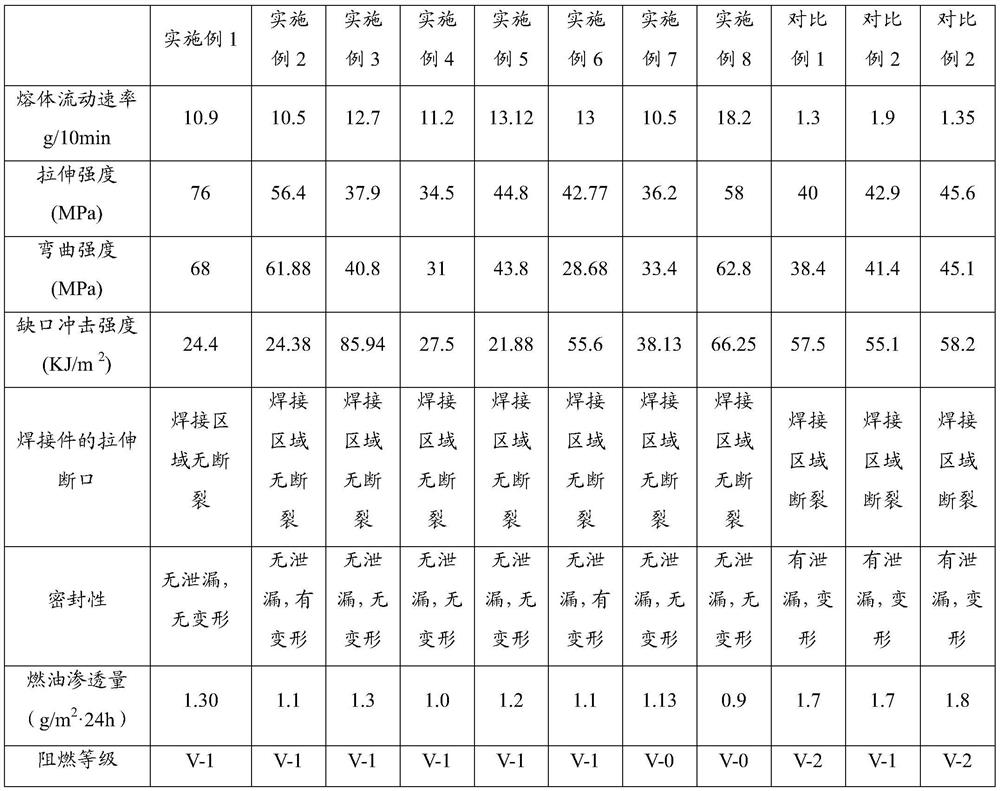

Method used

Image

Examples

Embodiment 9

[0040] The specific steps for preparing the combined urea fuel tank by utilizing the above-mentioned modified nylon composite material are:

[0041] (1) After the above-mentioned nylon composite material is melted, the melting temperature is 245°C-265°C, injected into the cavity of the mold through an injection molding machine, and the upper shell and the lower shell of the box are respectively obtained;

[0042] (2) After taking out the finished upper and lower shells from the mold, immediately put them into a steam incubator for cooling and forming. Preferably, the steam medium in the steam incubator is aqueous solution or potassium acetate solution, the steam temperature is 80-90°C, and the constant temperature time is 2-3h, or the steam temperature is 50-60°C, and the constant temperature time is 5-6h.

[0043] Said step (2) adopts steam at a certain temperature as the heat treatment medium during cooling molding, which is used to remove the internal stress generated in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com