Inner circle cutting power head with hydraulic adjusting device

A technology for adjusting devices and circular cutting, which is applied in the direction of knives for shearing devices, shearing devices, stone processing tools, etc. It can solve the problems of deformation cutting effect and multiple belt pulley transmission structures, so as to save space, save structure, Observe the effect of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

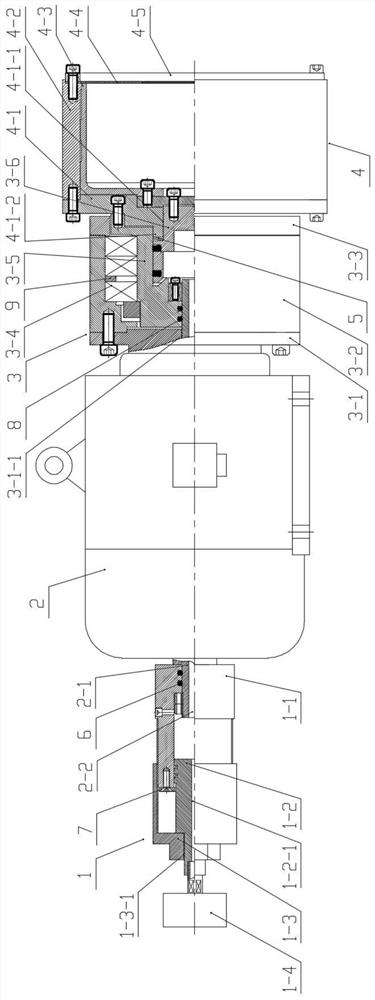

[0026] Such as figure 1 An internal cutting power head with a hydraulic adjustment device is shown, which includes a first hydraulic adjustment device 1, a drive motor 2, a second hydraulic adjustment device 3 and a cutter head device 4 arranged in sequence from left to right; The drive motor 2 is a coaxial double output shaft motor, and the middle part of the rotating shaft 2-1 of the drive motor 2 is provided with a through hole 2-2 along the axial direction;

[0027] The first hydraulic adjustment device 1 includes a first cylinder 1-1, a first piston 1-2, an adjustment sleeve 1-3 and a pressure gauge 1-4, and the left extended end of the rotating shaft 2-1 is controlled by the first The right side wall of the cylinder 1-1 protrudes into the inner cavity of the first cylinder 1-1, and the left extension end of the rotating shaft 2-1 is fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com