Bag nested type pipe automatic package machine

A technology of automatic packaging machine and automatic control device, which is applied in the direction of packaging, transportation packaging, multiple packages, etc., can solve the problems of overheating of packaging bags, exposed pipes, etc., and achieve the effects of easy operation, reduced working time, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

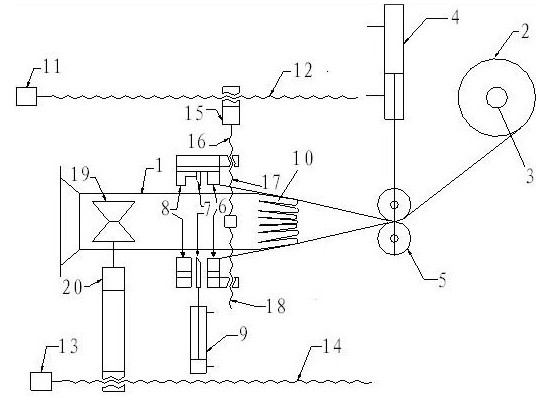

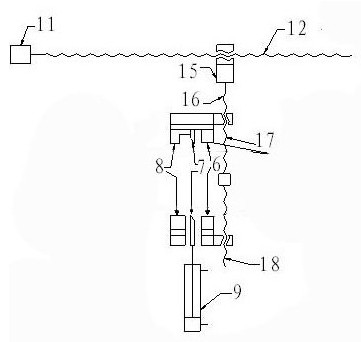

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

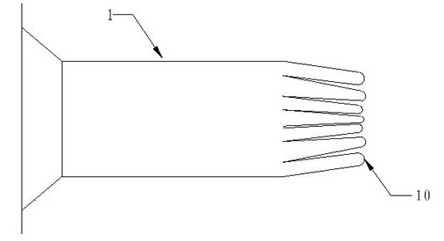

[0028] The structure of the present invention is as figure 1 As shown, a bagging type pipe automatic packaging machine includes a frame on which a first sliding device, a second sliding device, a plastic bag roll support, a plastic bag traction device, a suction bag shearing and sealing device, a guide Pipe 1, pipe pulling device and automatic control device;

[0029] like figure 1 As shown, the first sliding device is installed on the top of the frame along the horizontal direction, including the first motor 11 and the first screw mandrel 12, the first motor 11 is connected with the first screw mandrel 12, and the first screw mandrel 12 is connected with the suction bag scissors. The third motor 15 of cutting and sealing device is connected;

[0030] like figure 1 As shown, the second sliding device is installed below the frame in the horizontal direction, and it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com