Method for connecting trough-type base of steel trestle with embedded bolt in concrete bracket

A technology of steel trestle clamping and pre-embedded bolts, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as hindering bolt removal, increasing crane costs, and difficulty in positioning accurately, achieving enhanced safety, Easy to tighten, fast and accurate in place

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

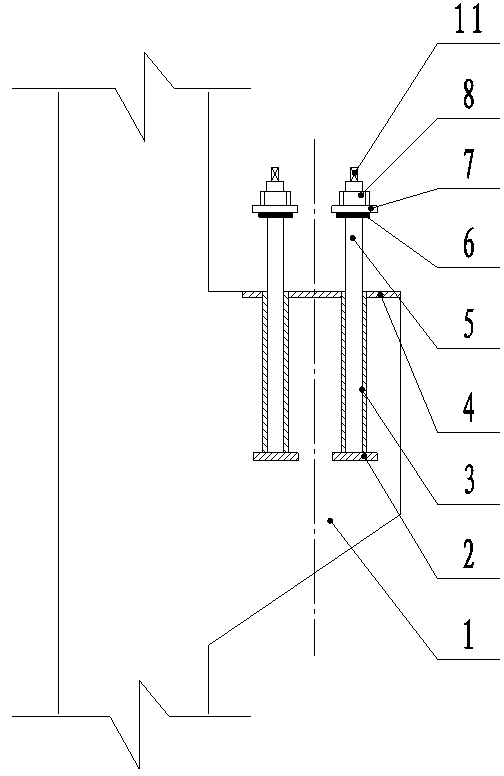

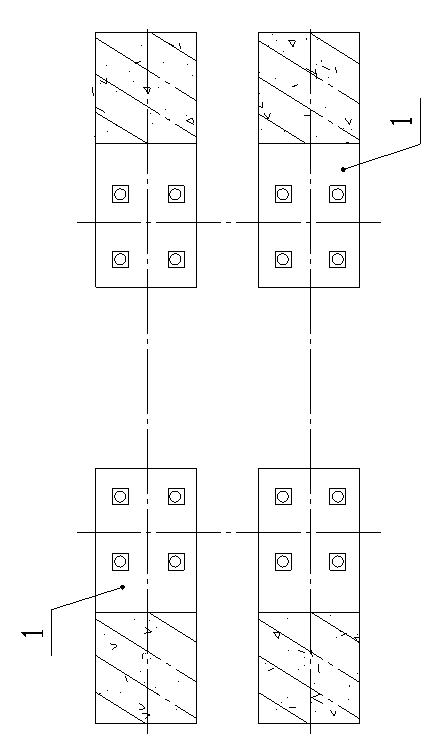

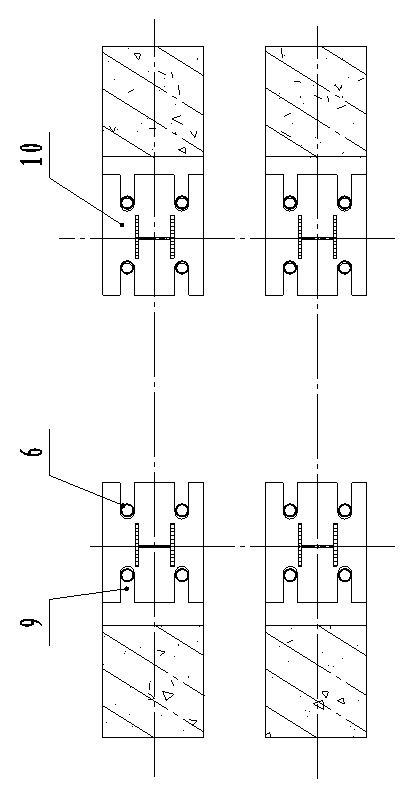

[0024] The connection method of the steel trestle card groove base and the embedded bolt in the concrete corbel of the present invention is carried out according to the following steps:

[0025] The first step is to weld and assemble the sleeve group. First, the end anchor steel plate 2 is welded to one end of the sleeve 3, and the other end of the sleeve 3 is welded to the pressure bearing plate 4. The pressure bearing plate 4 is welded with the same A total of four sleeves 3 with end anchor steel plates 2 welded at one end are welded in total. The sleeve 3 is threaded, and the stud 5 is fitted in the sleeve 3 through the thread and the stud 5 protrudes from the outer part of the sleeve 3. , at this point a set of socket sets is completed;

[0026] The second step is to fix the sleeve group, locate the pre-embedded position of the sleeve group on the concrete corbel according to the drawing, and then fix the multiple sleeve groups made according to the first step at their res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com