Heat-fusing body

A thermal fuse, metal shell technology, applied in the direction of heating/cooling contact switches, etc., can solve the problems of large amount of epoxy resin, affecting the appearance of the product, and the epoxy resin seal is prone to collapse, so as to reduce the amount of epoxy resin, The effect of improving electrical insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

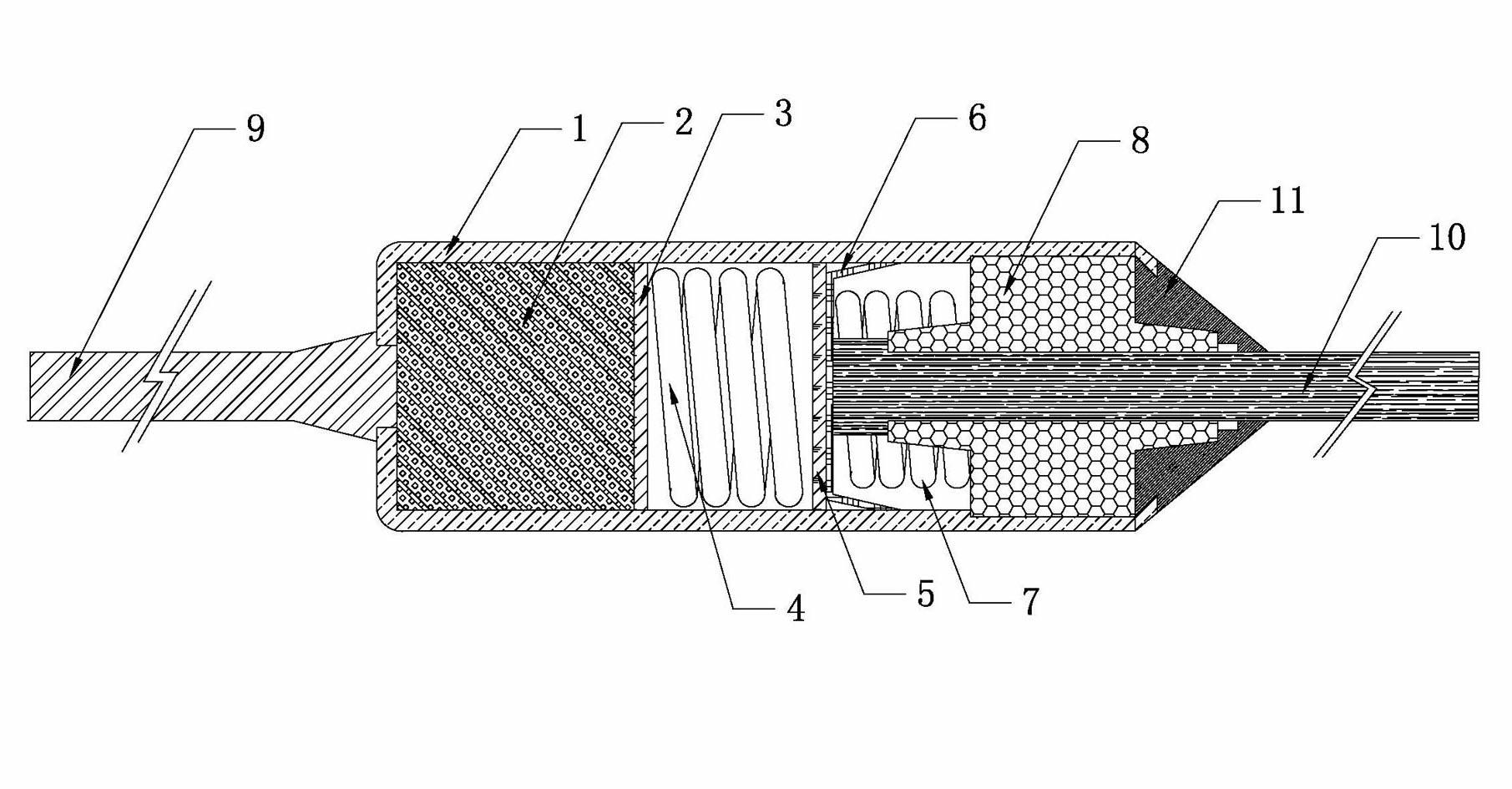

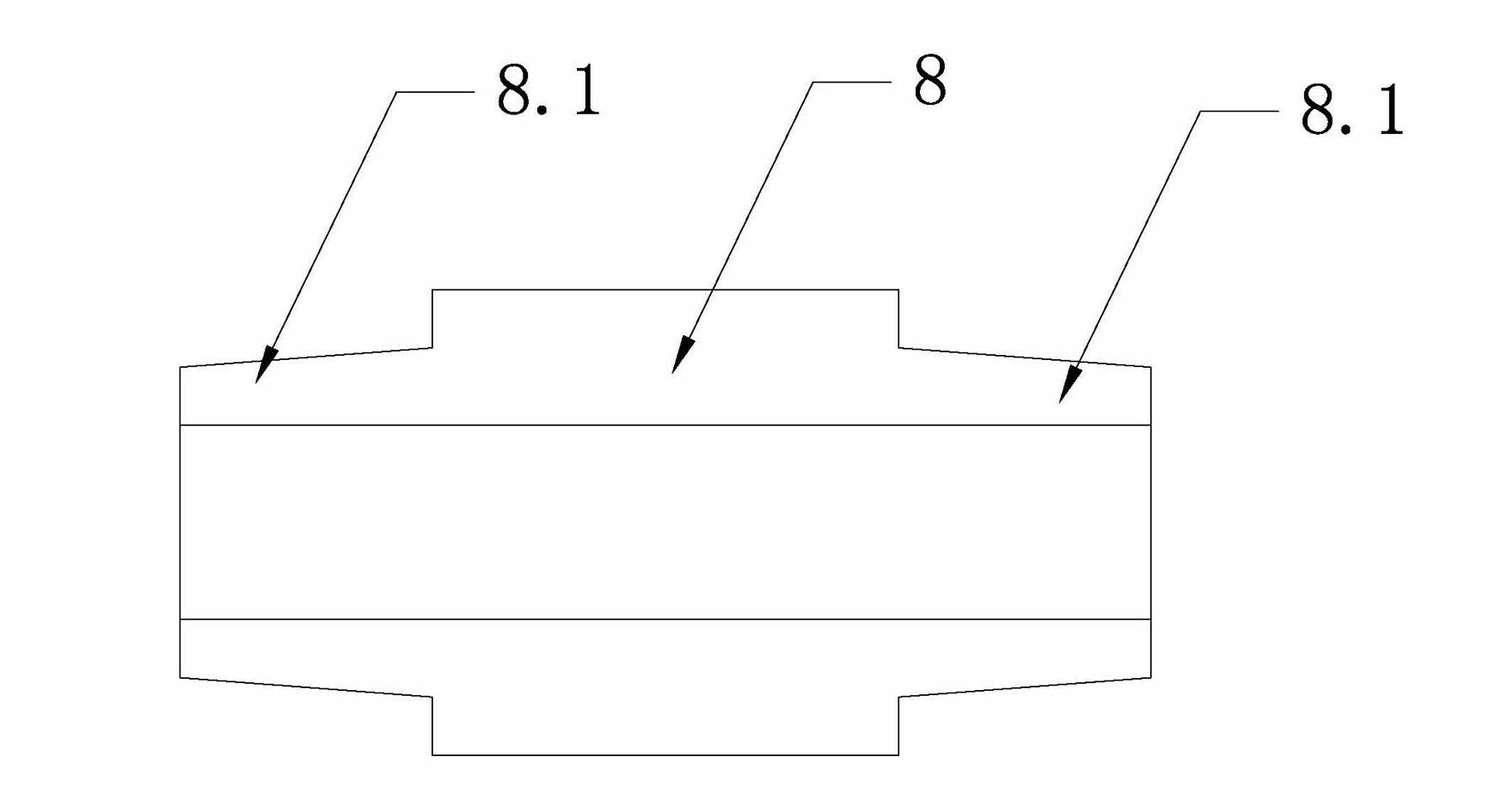

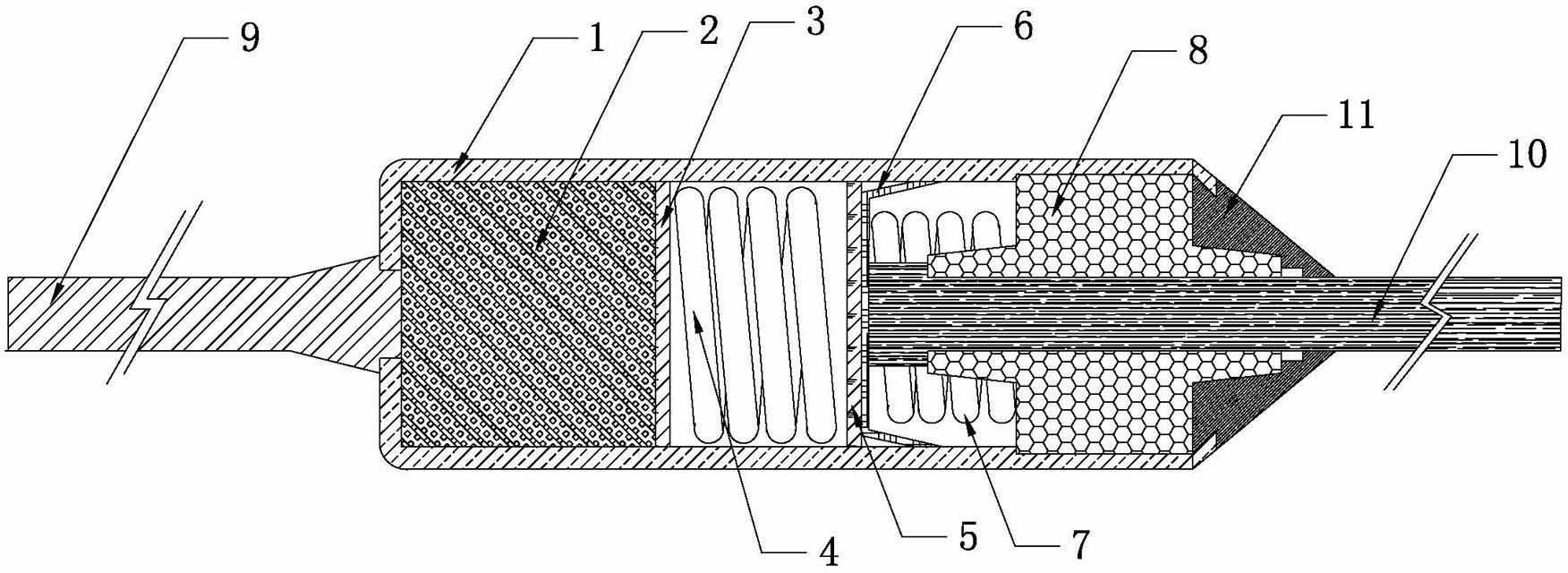

[0008] Such as figure 1 and figure 2 A thermal fuse is shown, including a metal shell 1, temperature-sensitive particles 2, front gasket 3, drum spring 4, rear gasket 5, breaking electrode 6, breaking spring 7, ceramic beads 8, riveting wire 9 and contacts Dot line 10; the port of the metal shell 1 at the junction of the contact line 10 and the ceramic bead 8 is sealed with epoxy resin 11; the characteristic is that there is a protruding head 8.1 at both ends of the ceramic bead 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com