Multilayer heat shrinkage film

A heat shrinkable film and outer layer technology, applied in the field of packaging materials, can solve the problems of reducing production efficiency, increasing processing steps, increasing costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] With the raw materials and proportions shown in Table 1, the raw materials used in each layer are first co-extruded into a multi-layer billet tube by means of multi-layer co-extrusion, and then the co-extruded multi-layer billet tube is passed through a warm water bath at 90°C Post-foam blown film, biaxially stretched 3.2 times in the machine direction (MD) and 3.6 times in the transverse direction (TD), then cooled to 15°C with air, and the cooled biaxially stretched The stretched multi-layer heat-shrinkable film is rolled up for further processing. All processed tube-packed films are processed into a width of 350mm for inspection.

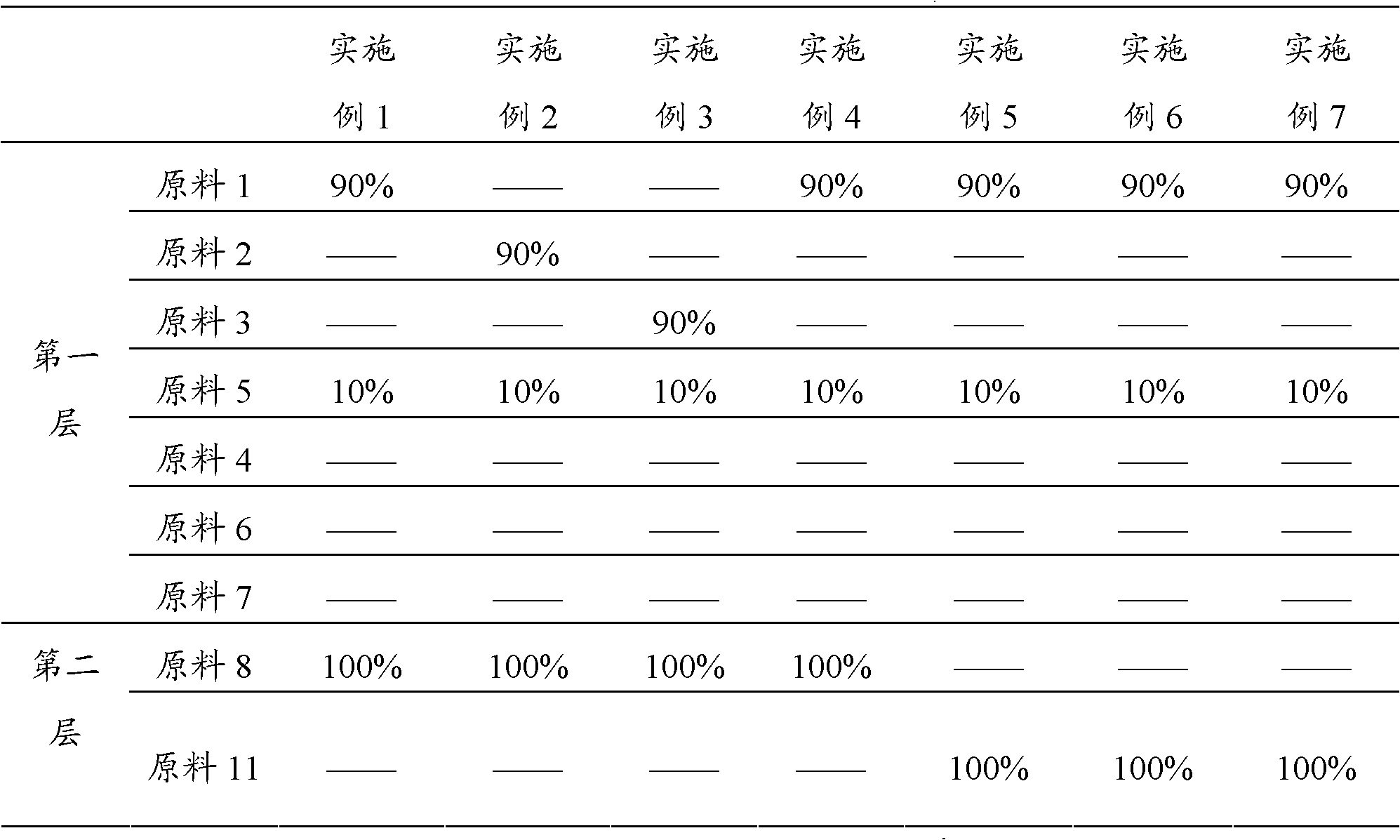

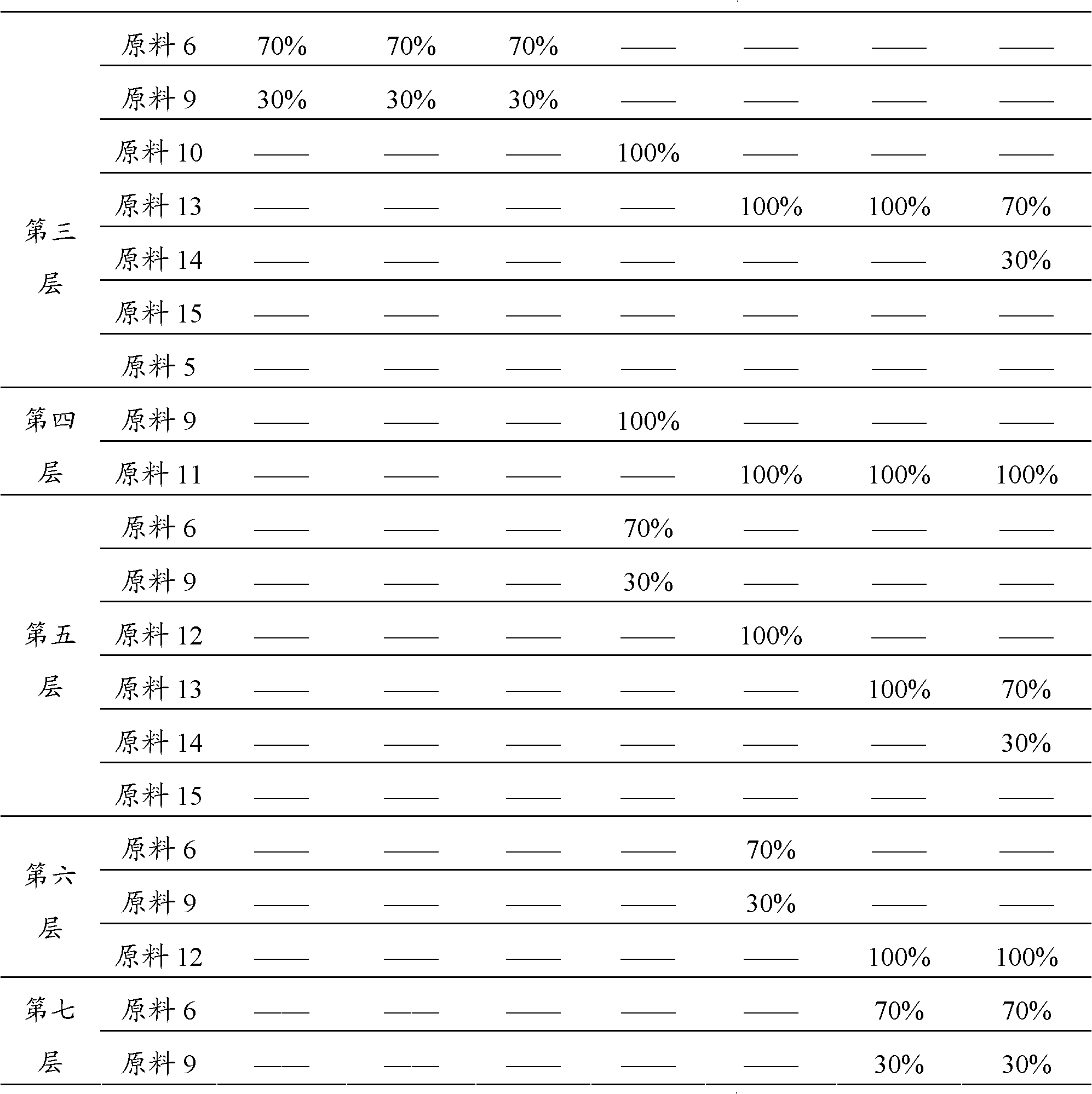

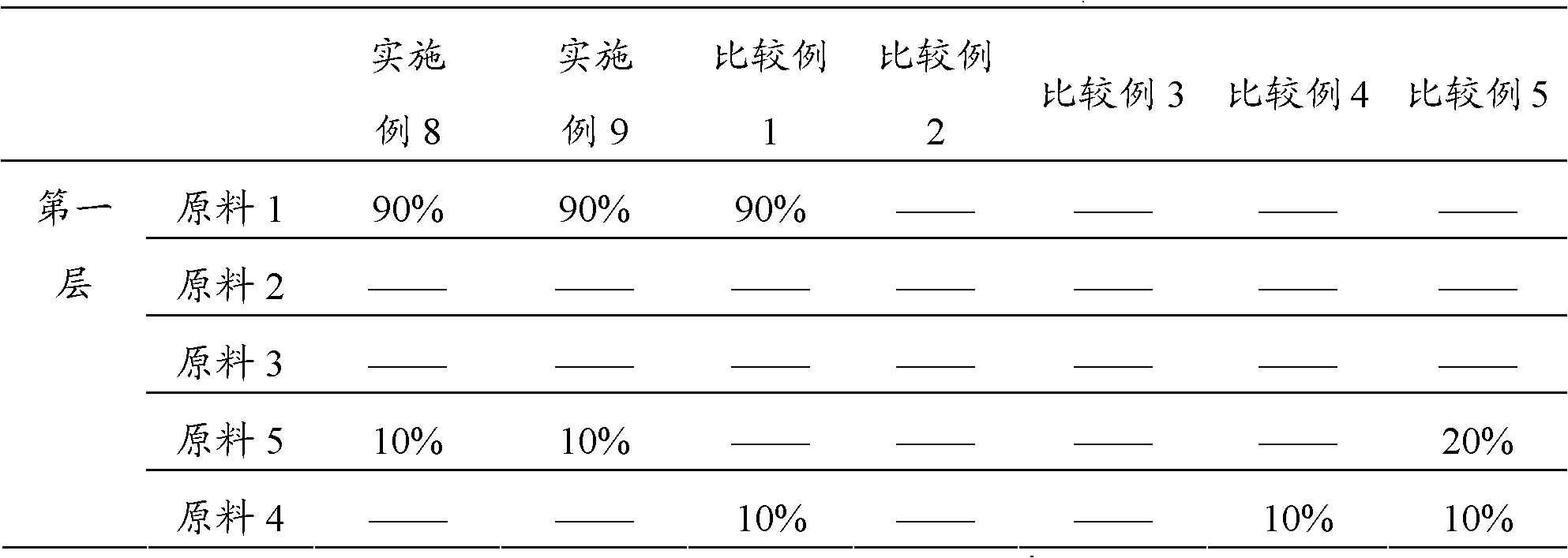

[0097] The raw material ratio of embodiment 1~embodiment 9, comparative example 1~5 is shown in Table 1;

[0098] The heat-shrinkable films prepared in Comparative Examples 2 and 3 were treated by an electron accelerator with an intensity of 5 MRad.

[0099] The process parameters of Examples 1 to 9 and Comparative Examples 1 to 5 are sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com