Container aligning system and method

A technology for aligning systems and containers, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of unguaranteed stacking quality, affecting the production efficiency of stacking machinery, and high viewing angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

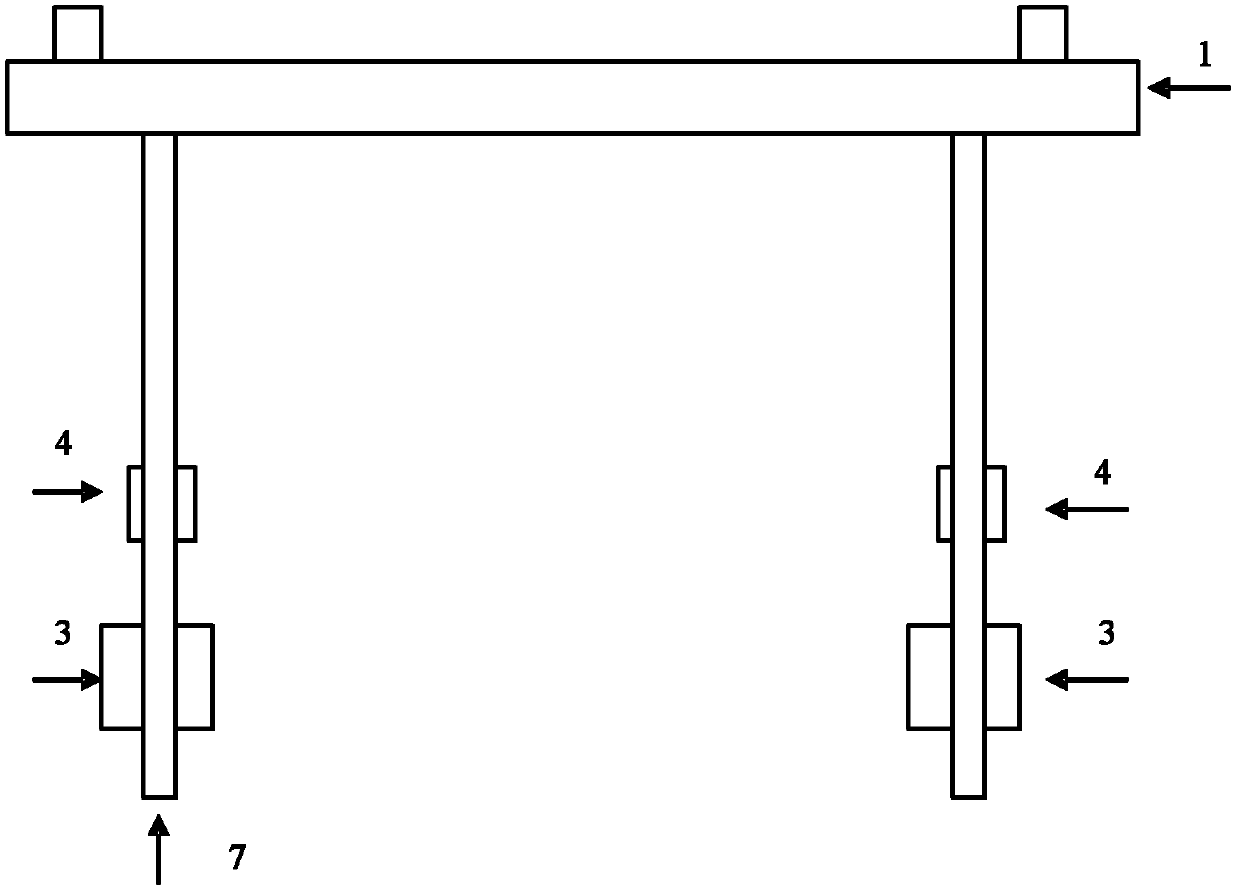

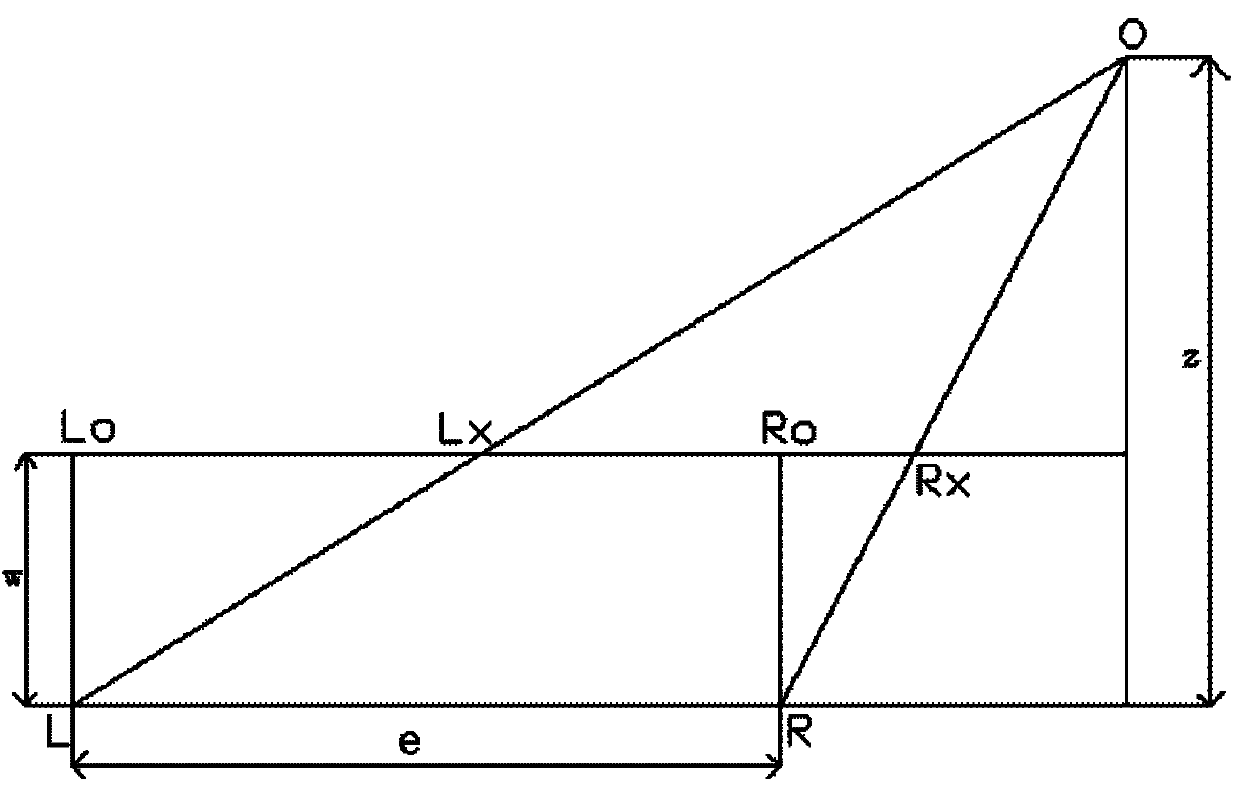

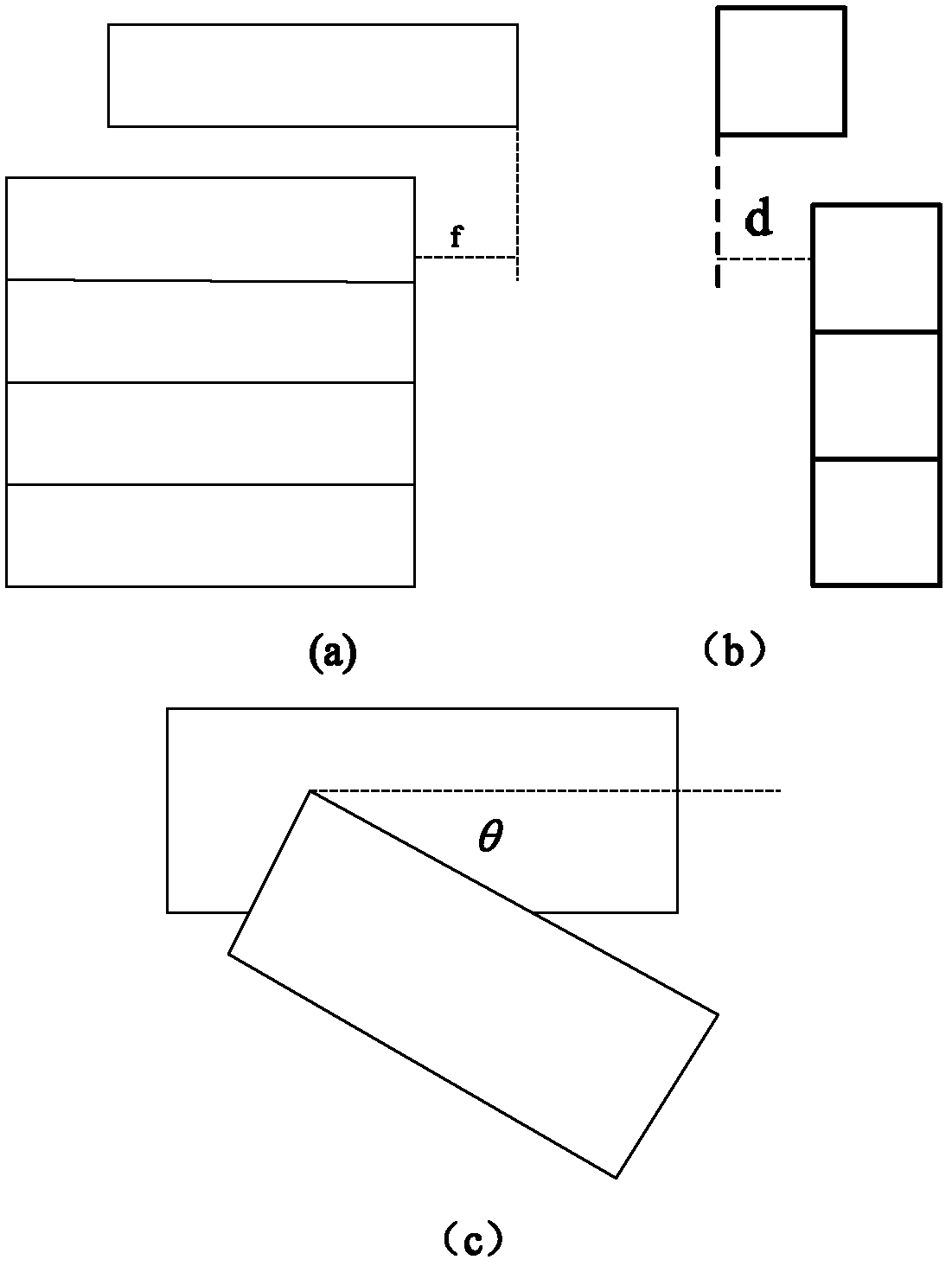

[0057] like Figure 1-5 As shown, the first layer of containers at the bottom is manually stacked by the driver of the stacking machine. When stacking the containers of the second layer and above, the driver manually lifts the container to the correct position to ensure that it is higher than the already Stacked containers. Then, the driver changes manual control to automatic control, and the system measures the position difference between the container on the spreader and the stacked container, and then controls the position of the container on the spreader until the stacking is successful, and then turns to For manual control, the driver manually controls to carry the next container, and repeats the above steps. If the position of the container is not automatically controlled, the driver can be informed of the position difference between the upper and lower containers in real time by using voice, text or image information, and then the driver manually controls the position ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com